I’ve spent years in the bearing business, talking to engineers like Rajesh from Mumbai. One question I hear often is about getting more life from conveyor systems. The answer often lies in the right bearing choice.

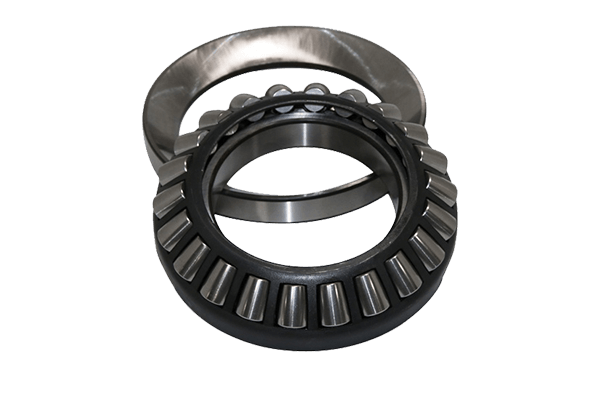

Spherical roller bearings are uniquely designed for heavy-duty conveyor pulleys and idlers because they can handle very high radial loads and moderate axial loads in both directions. Their key advantage is self-alignment, which compensates for shaft misalignment and housing deflections common in long conveyor frames, ensuring smooth operation and extended service life.

Conveyor systems are the backbone of industries from mining to logistics, and their downtime costs a fortune. The choice of bearing for pulleys and idlers isn’t just a component decision; it’s a critical business decision impacting maintenance budgets and production output. While many bearings can fit, few are engineered to thrive in the harsh, misaligned, and heavily loaded world of bulk material handling. Let’s look deeper at why spherical roller bearings are so often specified and what you need to know to make the best choice for your operation.

What are the disadvantages of spherical roller bearings?

Every solution has its trade-offs, and spherical roller bearings are no exception. Before you specify them for every application, it’s smart to understand their limitations.

The primary disadvantages of spherical roller bearings are their higher cost compared to some other roller bearings, slightly higher friction leading to elevated operating temperatures, and their limited suitability for very high-speed applications. Their design complexity and need for precise installation also contribute to these factors.

While spherical roller bearings are superstars in many heavy-load scenarios, they are not a universal fix. Understanding their weak points helps you apply them correctly.

A Critical Look at the Trade-Offs

Let’s break down the disadvantages into clear categories. This isn’t to discourage their use, but to ensure you deploy them where their strengths truly outweigh their weaknesses.

Cost and Economic Factors

For a procurement manager like Rajesh, balancing performance with budget is a daily task. Spherical roller bearings typically have a higher initial purchase price than comparable-sized cylindrical or deep groove ball bearings. This is due to their more complex internal design, with two rows of barrel-shaped rollers and a sophisticated spherical raceway. However, this is a classic case where Total Cost of Ownership (TCO) matters more than just the invoice price. The extended service life and reduced downtime in suitable applications often justify the higher upfront cost.

Performance Limitations

- Speed: They are not designed for very high rotational speeds. The large, heavy rollers and complex cage design create more centrifugal force and friction at high RPMs, leading to heat generation and potential lubrication breakdown. For high-speed spindles or machine tools, angular contact ball bearings or cylindrical rollers are usually better.

- Friction and Heat: The point contact between the rollers and raceways (before load application) and the self-aligning action inherently generate more friction than a precision-ground cylindrical roller bearing. This means they generally run hotter and may require more robust or frequent lubrication regimes.

- Precision: While available in precision classes like P5, they are not typically the first choice for applications requiring extreme rotational accuracy (like P4 or ABEC 7/9). Their self-aligning feature, while a strength for compensation, introduces a tiny amount of "play" not found in rigidly mounted bearings.

Operational and Maintenance Considerations

| Factor | Disadvantage | Practical Implication |

|---|---|---|

| Installation | More sensitive to installation errors. | Improper mounting (hammer blows, misalignment during press-fitting) can easily damage the delicate internal geometry and spherical surfaces. Proper tools and training are essential. |

| Lubrication | Demanding lubrication needs. | The complex internal space requires a sufficient quantity of high-quality grease or a reliable oil circulation system to reach all rolling contact surfaces and the cage. |

| Axial Load | Limited purely axial load capacity. | While they handle combined loads well, they are not thrust bearings. Applications with very high, continuous axial loads in one direction might need a dedicated tapered roller or thrust bearing pair. |

In my experience selling to distributors worldwide, the most common mistake is using a spherical roller bearing where a simpler, cheaper bearing would suffice. For a conveyor idler in a relatively clean, well-aligned environment with moderate loads, a deep groove ball bearing might be more cost-effective. The key is matching the bearing’s complexity to the application’s demands. I recall a client in Vietnam who switched all their fan motors to spherical rollers expecting longer life, only to face overheating issues. We helped them revert to deep groove bearings for the motors and reserve spherical rollers for their heavily loaded crushers, solving the problem and saving them money.

What loads can a spherical roller bearing handle?

This is the core of why we choose them. When a conveyor is piled high with ore or a crusher is shaking its frame, the bearing is the silent hero taking the punishment.

A spherical roller bearing is primarily designed to handle very high radial loads. It can also support significant axial (thrust) loads in both directions, typically up to about 25-35% of its radial load capacity. This makes it ideal for applications with heavy weight and potential shaft misalignment.

The term "high capacity" gets used a lot. But what does it really mean for your machinery? Let’s put some engineering perspective behind the marketing term.

Understanding Load Capacity in Practical Terms

Load capacity isn’t a single number. It’s a family of ratings that tell you how much force a bearing can withstand under different conditions and for how long. For engineers and buyers, these are the critical numbers in the catalog.

The Key Ratings: Basic Dynamic and Static Load

- Basic Dynamic Load Rating (C): This is the most important rating for most applications. It represents the constant radial load that a group of identical bearings can endure for one million revolutions with a 90% probability of survival. In simple terms, if a bearing has a C rating of 200 kN, and you apply a pure 200 kN radial load to it, it should theoretically last for 1 million revolutions. For longer life, you apply a load lower than C. This rating directly determines the theoretical service life (L10 life) of the bearing in a machine.

- Basic Static Load Rating (C0): This is the load a bearing can handle without permanent deformation (brinelling) that would cause vibration and noise. It matters for applications with very slow rotation, extreme shock loads, or where the bearing is stationary under load for long periods. You always want the maximum applied static load to be well below C0.

How Spherical Roller Bearings Excel with Combined Loads

The real magic happens when loads come from multiple directions. Imagine a conveyor tail pulley. The belt tension creates a strong radial load on the bearing (pushing down or sideways). But if the belt pulls slightly off-center or the shaft experiences thermal expansion, it also creates an axial load (pushing along the shaft). A deep groove ball bearing would struggle with this combination. A pair of tapered roller bearings would need precise adjustment.

A single spherical roller bearing handles both simultaneously. The two rows of rollers share the radial load. The spherical raceway in the outer ring allows the inner ring and rollers to tilt, which lets them accommodate the axial load by slightly changing the contact angle. This is why they are so popular on gearbox shafts, vibrating screens, and of course, conveyor pulleys—places where loads are rarely perfectly pure.

A Practical Example from Our Factory

We recently supplied a batch of 240 series spherical rollers to a mining equipment maker in South Africa for their new heavy-duty conveyor drives. Their calculation showed a steady radial load of 65 kN and an expected occasional axial thrust of up to 18 kN from belt drift. They needed a compact solution. A cylindrical roller bearing would handle the radial load but offer zero axial support. Using two tapered rollers would make the housing wider. The single spherical roller bearing, with its C rating of 325 kN and ability to handle the axial load (which was well under 35% of its radial capacity), was the perfect, space-saving fit. It simplified their housing design and reduced assembly time.

What roller bearing has the greatest load capacity?

When the load is the absolute king of your design criteria, and everything else is secondary, you need to know which bearing wears the crown.

Among standard roller bearing types, spherical roller bearings generally have the highest radial load capacity for a given bore size and outer diameter. Their design, with two rows of rollers maximizing contact area with the raceways, allows them to support heavier weights than single-row cylindrical or tapered roller bearings.

But "greatest" needs context. Load capacity is a battle with several contenders, each with different specialties. Pitting them against each other reveals why spherical rollers often come out on top for pure, brutal radial force.

The Heavyweight Championship: Comparing Bearing Types

Let’s stage a comparison. Imagine we have three bearings with the exact same bore (shaft size) and outer diameter (housing size). They are a single-row cylindrical roller bearing, a tapered roller bearing (usually considered in pairs for fair comparison), and a spherical roller bearing. Which can hold the most weight?

Why Spherical Roller Bearings Win on Pure Radial Load

- Two Rows of Rollers: This is the biggest advantage. A single-row cylindrical bearing has one set of rollers. A spherical has two. This essentially doubles the number of load-carrying elements sharing the force within the same width envelope.

- Optimal Line Contact: The barrel-shaped (spherical) rollers make long, favorable line contact with the inner and outer raceways. This spreads the load over a larger surface area compared to the point contact of ball bearings, dramatically reducing stress.

- Robust Design: They are built for harsh environments. Large roller diameters, strong cages, and high-quality forged steel rings are standard, all contributing to their ability to resist deformation under load.

The Challengers: When Others Might Compete

- Cylindrical Roller Bearings (Single/Double Row): For pure, perfectly aligned radial loads, a high-precision double-row cylindrical roller bearing can have a very high capacity and can run at higher speeds than a spherical. However, it has essentially zero axial load capacity. It’s a specialist, not an all-rounder.

- Tapered Roller Bearings: They are fantastic for combined radial and axial loads, especially when the axial load is predominantly in one direction. However, they are almost always used in opposed pairs to handle bidirectional thrust. When you add up the space and load capacity of two tapered bearings, a single spherical bearing often provides comparable or higher radial capacity in a more compact and simpler package, with the bonus of built-in misalignment tolerance.

- Cylindrical Roller Thrust Bearings: For purely axial loads, these have an immense capacity. But they cannot handle any radial load whatsoever. They are a completely different tool for a different job.

A Data-Driven Perspective

Look at any major bearing manufacturer’s catalog. Compare the Basic Dynamic Load Rating (C) for bearings in the same "size family." For example, in a common 320 size series (100mm bore, 215mm OD), you might find:

| Bearing Type | Approx. Basic Dynamic Load Rating (C) | Key Characteristic |

|---|---|---|

| Deep Groove Ball Bearing | ~ 180 kN | General purpose, low friction. |

| Single-Row Cylindrical Roller Bearing | ~ 340 kN | High radial, no axial capacity. |

| Tapered Roller Bearing (Single) | ~ 240 kN | Good combined load, one direction. |

| Spherical Roller Bearing | ~ 450 kN | Highest radial, good bidirectional axial. |

The data speaks for itself. For an importer like Rajesh’s company, "IndoMotion Parts," this is crucial. When a local mining customer comes to him asking for a bearing that can survive under a massive rotary dryer, recommending the spherical roller bearing isn’t just an upsell; it’s providing the technically superior solution that will build trust and prevent premature failures. It’s the bearing you specify when failure is not an option and the load is the primary design challenge.

What are spherical roller bearings used for?

Knowing a bearing’s specs is one thing. Seeing where it solves real-world problems is another. Their use cases tell the story of modern heavy industry.

Spherical roller bearings are used in heavy machinery where high loads, shaft misalignment, or harsh conditions are present. Common applications include conveyor pulleys and idlers, gearboxes, vibrating screens, industrial fans, agricultural equipment, crane sheaves, and rolling mill roll necks.

If you walk through a mine, a cement plant, or a steel mill, you’ll find spherical roller bearings working hard in some of the toughest spots. Their design directly answers the challenges these industries face.

The Workhorses of Industry: A Sector-by-Sector Breakdown

Let’s explore the specific roles these bearings play. This isn’t an exhaustive list, but it covers the major industries where FYTZ Bearing ships containers of these products every month.

Material Handling: The Classic Home

This is where our conversation started. Conveyor systems are ideal applications.

- Head and Tail Pulleys: These endure high belt tension (radial load) and potential misalignment from frame settling or thermal expansion.

- Idler Rolls: Especially impact idlers near loading points, which suffer shock loads from falling material. The bearing’s robustness is key.

- Bucket Elevators and Screw Conveyors: Similar challenges with weight, misalignment, and often contaminated environments.

Mining and Mineral Processing

A brutal environment demanding rugged components.

- Vibrating Screens: These machines shake violently to separate materials. Spherical rollers handle the extreme, oscillating radial loads and the slight axial movements from the vibration mechanism.

- Crushers and Grinding Mills: Massive, uneven forces from crushing rock. High radial load capacity and shock resistance are non-negotiable.

- Rotary Kilns and Dryers: Extremely large, slowly rotating drums. The bearings must support enormous weight (high static loads) and compensate for significant sag and thermal distortion of the long shell (self-alignment).

Power Generation and Heavy Manufacturing

- Industrial Fans and Blowers: Especially large induced-draft fans in power plants. They run hot, have heavy impellers (radial load), and can experience shaft flex (misalignment).

- Gearboxes: Particularly in wind turbines and large industrial drives. They transmit high torque, creating heavy radial and axial forces on the output shafts.

- Paper Mill Rollers: Wide rollers that must stay in precise alignment under load to produce uniform paper. The self-aligning feature is critical here.

- Steel Mill Roll Neck Bearings: This is a premier application. The bearings support the rolls that shape red-hot steel. They face extreme temperatures, high speeds, and incredible rolling forces. Special heat-resistant and high-precision spherical rollers are used.

Why Our Customers in Emerging Markets Choose Them

My daily conversations with distributors in countries like Brazil, India, and Egypt highlight a common theme: the drive for reliability. Rajesh in Mumbai isn’t just buying a box of bearings; he’s buying uptime for his customers. When a local sugar mill’s crusher goes down during harvest season, every hour of downtime means lost revenue. By supplying them with high-quality spherical roller bearings that can handle the shock loads of cane processing and tolerate the less-than-perfect alignment of older equipment, Rajesh becomes a reliability partner, not just a parts supplier.

The use case defines the needed features. For a vibrating screen, we might emphasize our bearings with reinforced cages and special heat treatment for shock resistance. For a slow-turning dryer, we highlight the high static load rating and our sealing options to keep out dust. This application-focused thinking is what separates a generic supplier from a true solution provider like FYTZ.

Conclusion

Choosing the right bearing is about matching engineering strengths to real-world challenges. For the heavy loads and inevitable misalignments of conveyors and other rugged machinery, high-capacity spherical roller bearings often provide the most reliable and cost-effective solution over the long term.