Conveyor systems keep your production moving, but unexpected bearing failure can bring everything to a costly halt. I’ve seen it happen too often in my years dealing with bearings. The right deep groove ball bearing is not just a part; it’s a commitment to smooth operation and less downtime.

Selecting and sourcing the right deep groove ball bearings for conveyor systems involves balancing load capacity, speed, and sealing against contaminants. Successful sourcing means finding a reliable supplier who offers consistent quality, technical support, and a value-driven partnership, not just the lowest price. This guide shares practical tips from my experience to help you make better decisions.

Choosing bearings can feel like a maze of specifications and suppliers. I understand the pressure to keep costs down while ensuring reliability. Let’s break down the key parts of the bearing itself first. Then we can look at how to choose and source them wisely for your specific needs. This knowledge will help you talk confidently with suppliers and avoid common mistakes.

What are the 4 major parts of a deep groove ball bearing?

If a bearing fails, you need to know what to look for. I remember a client who kept replacing entire bearings when only the cage was damaged. Understanding the four main parts helps you diagnose problems, communicate with suppliers, and even spot quality differences. It’s the foundation of smart selection.

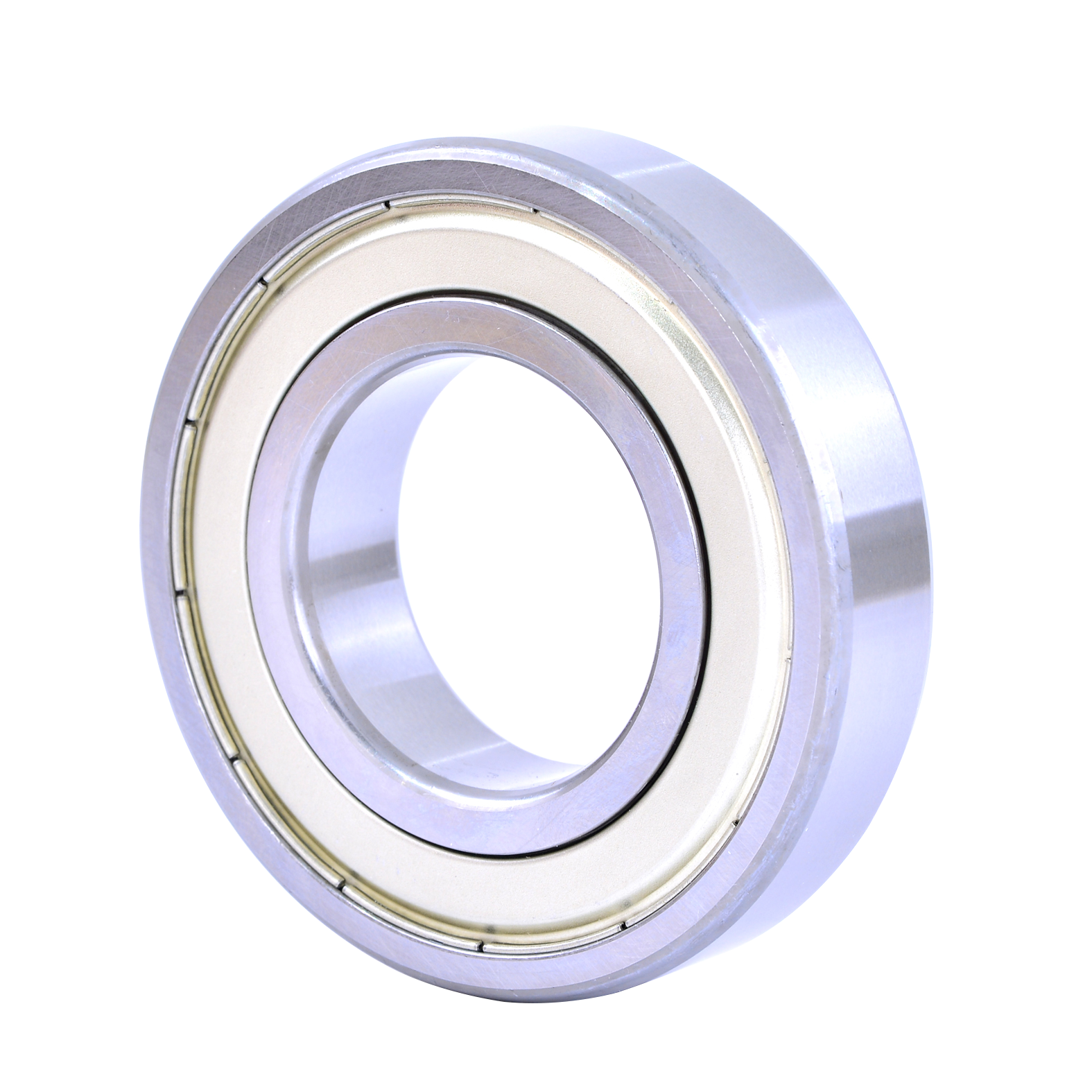

A deep groove ball bearing consists of four key components: the inner ring, the outer ring, the steel balls, and the cage (or retainer). The inner and outer rings have deep raceways to guide the balls. The balls carry the load, and the cage keeps them evenly spaced to prevent contact and reduce friction.

A Closer Look at Each Component’s Role

Knowing the parts is one thing. Understanding how each one affects performance and failure is another. Let’s examine each part’s function and what to watch for.

The Inner and Outer Rings

These rings are the backbone. They are typically made from high-carbon chromium steel. The deep, grooved raceways machined into them are precisely shaped. This shape controls how the balls roll. The precision of this machining directly affects the bearing’s noise level, vibration, and lifespan. A common issue I see is brinelling. This is when impact loads create permanent dents in the raceways. You see this often in conveyor systems where heavy items are dropped onto the belt. Choosing a bearing with the right hardness and a robust design can help prevent this.

The Steel Balls

These are the heart of the bearing’s motion. Their quality is non-negotiable. They must be perfectly spherical and have an extremely smooth surface. Even microscopic imperfections create vibration and wear down the raceways faster. The grade of the balls (like G10, G16) defines their tolerance. A higher grade means more precision and better performance, especially in high-speed applications. The number and size of the balls determine the load capacity. More or larger balls can handle heavier loads, but they might increase friction at very high speeds.

The Cage (Retainer)

This part is often overlooked, but it’s critical. The cage’s job is to separate the balls. It prevents them from rubbing against each other. This reduces friction, heat, and wear. Cages can be made from steel, brass, or engineered polymers (like polyamide).

| Cage Material | Key Advantages | Common Applications / Notes |

|---|---|---|

| Steel | High strength, good heat resistance, very durable. | Suitable for high-speed, high-temperature, and heavy-load situations. Common in industrial settings. |

| Brass | Good strength, smooth operation, lower friction. | Often used for low-noise applications. Provides good guidance for the balls. |

| Polyamide (Polymer) | Lightweight, self-lubricating, very quiet operation. | Excellent for low to medium loads and speeds. Sensitive to very high temperatures and certain chemicals. |

The choice of cage affects the bearing’s maximum speed (the "limiting speed") and its suitability for certain environments. For example, a polymer cage might not survive in a high-heat area near a dryer on a conveyor line. When you discuss with a supplier like us at FYTZ, specifying the operating environment helps us recommend the right cage material. Seeing a failed cage can tell you a lot. A melted polymer cage points to overheating. A cracked steel cage might indicate severe vibration or misalignment.

What factors should be considered when selecting a bearing for a specific application?

Picking a bearing from a catalog based only on size is a gamble. I’ve talked to many procurement managers who face early failures because the bearing wasn’t matched to the job. The right choice prevents costly shutdowns and rebuilds. It starts with asking the right questions about the application.

Key selection factors include the type and magnitude of the load (radial, axial, or combined), the required operating speed, the environmental conditions (dust, moisture, temperature), and the desired lifespan and maintenance schedule. You must balance these factors, as optimizing for one (like extreme load) might compromise another (like very high speed).

Balancing the Critical Selection Criteria

Selection is a balancing act. You rarely get the perfect bearing for every factor. The goal is to find the best compromise for your specific situation. Let’s break down the main factors into a practical framework.

1. Understanding Load and Speed: The Primary Drivers

The load tells the bearing what to carry. The speed tells it how fast to do it. These two factors are deeply connected.

- Load Type and Size: Is the load mostly pushing down on the shaft (radial load), pushing along the shaft (axial load), or both? Deep groove ball bearings handle radial loads best, but they can take moderate axial loads from either direction. For heavy axial loads, other bearings like taper roller bearings are better. You must calculate the expected load. An undersized bearing will fail quickly from fatigue.

- Operating Speed: Every bearing has a "limiting speed." Exceeding it generates excessive heat from friction. This heat can degrade the lubricant and damage the cage or balls. High-speed applications need bearings with precision-grade balls, special cages (often phenolic resin or machined brass), and sometimes special lubrication. Remember, a high load rating and a high speed rating often conflict. A bearing built for massive loads is usually not the best for extremely high speeds.

2. The Environment: The Silent Killer

The operating environment can destroy even a perfectly sized bearing. You must defend the bearing from its surroundings.

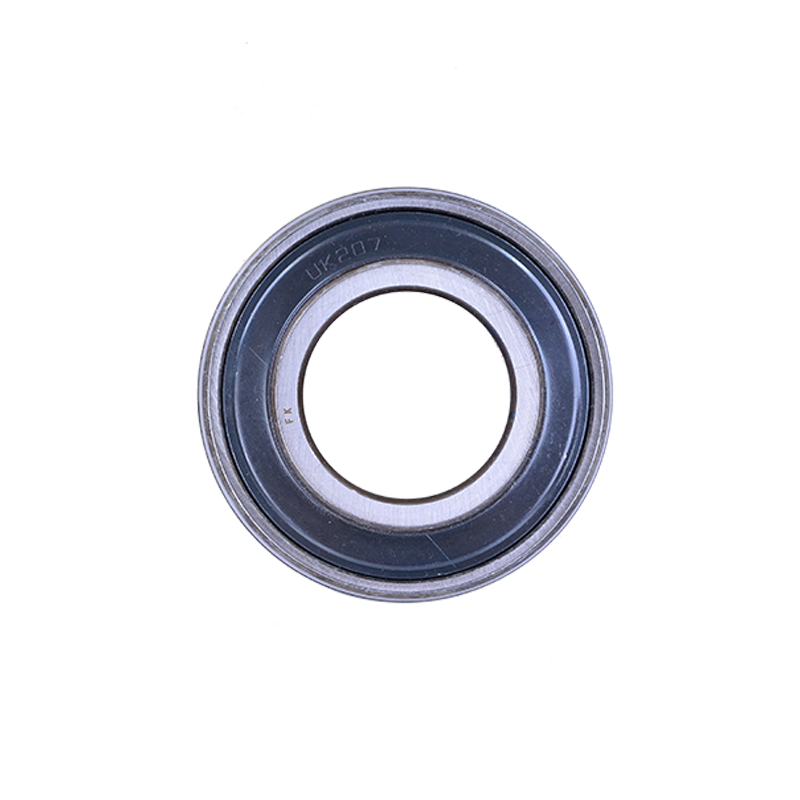

- Contaminants: Dust, grit, and water are enemies. They get inside the bearing, act like grinding paste, and cause rapid wear. For dirty or wet environments (like mining or food processing conveyors), sealed or shielded bearings are essential. Rubber-contact seals offer the best protection but add a little more friction.

- Temperature: Extreme heat or cold affects the bearing steel, the cage material, and the lubricant. High temperatures can soften the metal, reduce hardness, and cause lubricants to thin or oxidize. Low temperatures can make lubricants stiffen. You may need special heat-treated steel or different lubricants for temperature extremes.

3. Precision, Lifespan, and Maintenance

These are your performance and cost goals.

- Precision Class: Bearings are made to different precision levels (ISO classes like P0, P6, P5). A higher precision class (P5) has tighter tolerances on dimensions and running accuracy. This results in smoother, quieter, more efficient running with less vibration. It is crucial for high-speed spindles or precision machinery. For a standard conveyor roller, P0 (Normal class) is often sufficient. Using a P5 bearing there is often an unnecessary cost.

- Expected Lifespan (L10 Life): This is a calculated rating. It tells you the hours at which 90% of a group of identical bearings are expected to still be operating. It’s based on load and speed. You need a bearing whose L10 life exceeds your machinery’s service intervals or desired overhaul period.

- Lubrication and Sealing: Is the bearing pre-lubricated and sealed for life? Or will it be re-lubricated? "Sealed for life" bearings are low-maintenance but have a finite life. Bearings with re-lubrication features can last much longer but require maintenance access and schedule. Your choice here impacts your total cost of ownership.

The table below summarizes how these factors guide the specification:

| Application Factor | Key Question | Bearing Specification Implication |

|---|---|---|

| High Load | Is the load primarily radial, axial, or combined? How heavy is it? | Requires bearing with high Basic Load Rating. For heavy axial loads, consider angular contact or taper roller bearings. |

| High Speed | What is the shaft rotation speed (RPM)? | Requires high-precision balls, special cage (phenolic, machined brass), and possibly cooling features. Check the catalog’s "limiting speed." |

| Dirty/Wet Environment | Is there dust, fibers, splash, or steam? | Mandatory use of sealed bearings (RS or 2RS type). Rubber contact seals provide the best protection. |

| High Temperature | What is the ambient and operating temperature range? | Requires heat-stabilized steel (suffix S1, S2, etc.), high-temperature lubricant, and a cage material suited for heat (steel, brass). |

| Low Noise/Vibration | Is the application sensitive to noise (e.g., office equipment, medical devices)? | Requires high precision class (P5 or above), vibration-grade steel (Z1, Z2, etc.), and a quiet cage material (polyamide, brass). |

| Maintenance Access | Can the bearing be easily reached for re-greasing? | If yes, an open bearing with re-lubrication features may extend life. If no, a sealed-for-life bearing is better. |

What are the advantages of deep groove ball bearings?

Why are these bearings used everywhere, from conveyor rollers to electric motors? Their popularity isn’t an accident. I recommend them for a wide range of applications because their strengths match common industrial needs perfectly. Knowing these advantages helps you apply them correctly.

Deep groove ball bearings offer versatility, low friction, high-speed capability, minimal maintenance, and cost-effectiveness. They handle both radial and axial loads, run smoothly, and are available in many standardized sizes, making them a reliable, economical choice for countless applications.

Why Their Design Leads to Widespread Success

The advantages come from the simple, clever design. Let’s connect each benefit back to the physics and construction of the bearing.

1. Versatility in Load Handling

This is their standout feature. The deep, continuous raceways on both rings allow the balls to sustain not just radial loads but also significant axial loads in both directions. Many other bearing types are specialists. Tapered roller bearings are great for heavy axial loads but in one direction only. Cylindrical roller bearings handle very high radial loads but almost no axial load. The deep groove ball bearing is a good all-rounder. For a conveyor system, where rollers experience some side thrust and misalignment, this versatility is a major safety factor.

2. Low Friction and High-Speed Operation

The point contact between the balls and the raceways creates very little rolling resistance. Compared to bearings with line contact (like roller bearings), they generate less heat from friction. This lower friction allows them to achieve higher rotational speeds. This makes them the first choice for electric motors, spindles, and any high-RPM application. The low friction also translates directly to energy efficiency. A system with low-friction bearings uses less power to overcome resistance.

3. Low Maintenance and Reliability

When sealed and pre-lubricated, deep groove ball bearings are essentially "fit and forget" components for their design life. They don’t require constant adjustment or complex lubrication systems. This simplicity reduces the need for skilled maintenance labor and lowers the total cost of ownership over time. Their robust design, when properly selected, provides predictable and long service life. For a procurement manager like Rajesh, this reliability means fewer emergency orders and happier customers.

4. Standardization and Cost-Effectiveness

They are produced in the widest range of standardized sizes (ISO 15 series). This global standardization means they are interchangeable between brands (within the same tolerance class). This creates huge economies of scale in manufacturing, making them very cost-competitive. You can source a 6205 bearing from multiple suppliers, which gives you flexibility and negotiating power. For an importer/distributor, stocking these standard sizes guarantees a steady market demand.

5. Quiet and Smooth Operation

The continuous rolling motion of the balls, guided by the deep grooves, results in very smooth rotation with minimal vibration. This is why they are used in applications where noise matters, from household appliances to office equipment. High-precision grades (like the P5/P6 we offer at FYTZ) take this further, producing exceptionally quiet running for sensitive machinery.

What are the disadvantages of deep groove ball bearings?

No component is perfect for every job. I’ve also seen the consequences of using a deep groove ball bearing where it wasn’t suited. Understanding their limits protects you from application failures and guides you to better alternatives when needed. It’s about using the right tool.

The main disadvantages include limited axial load capacity compared to dedicated thrust bearings, sensitivity to misalignment and shock loads, and potential for faster wear in contaminated environments if not properly sealed. They are generalists, not specialists for extreme conditions.

Recognizing Their Limits to Avoid Costly Mistakes

Being aware of these weaknesses allows you to mitigate them or choose a different bearing. Let’s explore each disadvantage and its practical implications.

1. Limited Capacity for Heavy Axial Loads

This is the most important limitation. While they can handle axial loads, there is a limit. The contact angle in a deep groove bearing is essentially zero. Under pure axial load, the balls can skid or slide instead of rolling smoothly, especially if the load is too high. This causes rapid heat generation, lubrication breakdown, and early failure. For applications with predominantly heavy axial loads—like vertical pumps, crane hooks, or screw jacks—a dedicated angular contact ball bearing or a thrust bearing is a far better choice. They are designed with a built-in contact angle to handle axial force efficiently.

2. Sensitivity to Misalignment

Deep groove ball bearings are designed for precise alignment between the shaft and the housing. They have very little internal ability to compensate for angular misalignment. If the shaft is not perfectly parallel to the housing bore, it creates a bending moment on the bearing. This forces the balls to run on the edge of the raceway. The result is excessive stress, noise, heat, and drastically reduced life. For applications where shaft deflection or installation inaccuracy is likely (like long conveyor shafts or agricultural equipment), self-aligning ball bearings or spherical roller bearings are superior. They have a spherical outer ring that allows the inner ring to pivot, correcting for misalignment.

3. Vulnerability to Shock and Impact Loads

The point contact that gives them low friction also concentrates stress. A sudden, heavy impact—like a jammed conveyor belt or a dropped heavy object—can overwhelm this contact point. It can cause brinelling (permanent dents in the raceways) or even crack the rings. Roller bearings, with their line contact, distribute shock loads over a larger area and are generally more resilient. In harsh environments with frequent impacts, a cylindrical or spherical roller bearing might be more durable.

4. Performance in Harsh Environments (Without Protection)

An open deep groove ball bearing will fail quickly if exposed to abrasive dust or moisture. The precision gaps are easily invaded. While sealed versions solve this, the seals themselves have limits. High-temperature environments can degrade rubber seals. Very abrasive fine dust can eventually wear through seal lips. In extremely harsh conditions, additional external protective measures (like labyrinth seals or protective covers) might be needed, or a different bearing type with integral heavy-duty sealing could be considered.

The table below contrasts deep groove ball bearings with common alternatives for specific challenges:

| Application Challenge | Deep Groove Ball Bearing Suitability | Often Better Alternative |

|---|---|---|

| Very Heavy Radial Loads | Moderate. May require a larger bearing size. | Cylindrical Roller Bearing: Higher radial load capacity in the same envelope. |

| Very Heavy/Pure Axial Loads | Poor. Risk of ball skidding and overheating. | Thrust Ball Bearing or Taper Roller Bearing: Designed specifically for axial loads. |

| Shaft Misalignment | Poor. Intolerant of angular error. | Self-Aligning Ball Bearing or Spherical Roller Bearing: Can compensate for misalignment. |

| Extreme Shock/Impact Loads | Moderate. Prone to brinelling. | Spherical Roller Bearing or Cylindrical Roller Bearing: Better impact resistance. |

| Very High Speed with Precision | Excellent (with high-precision grade). | Angular Contact Ball Bearing: Often used for ultra-high-speed spindles. |

| Compact Design Needs | Excellent. Simple, low cross-section. | Needle Roller Bearing: Even smaller cross-section for very high radial load in confined space. |

Conclusion

Choosing the right deep groove ball bearing requires understanding its parts, your application’s demands, and its pros and cons. Partnering with a knowledgeable supplier ensures you get a reliable component, not just a cheap part, keeping your conveyors running smoothly.