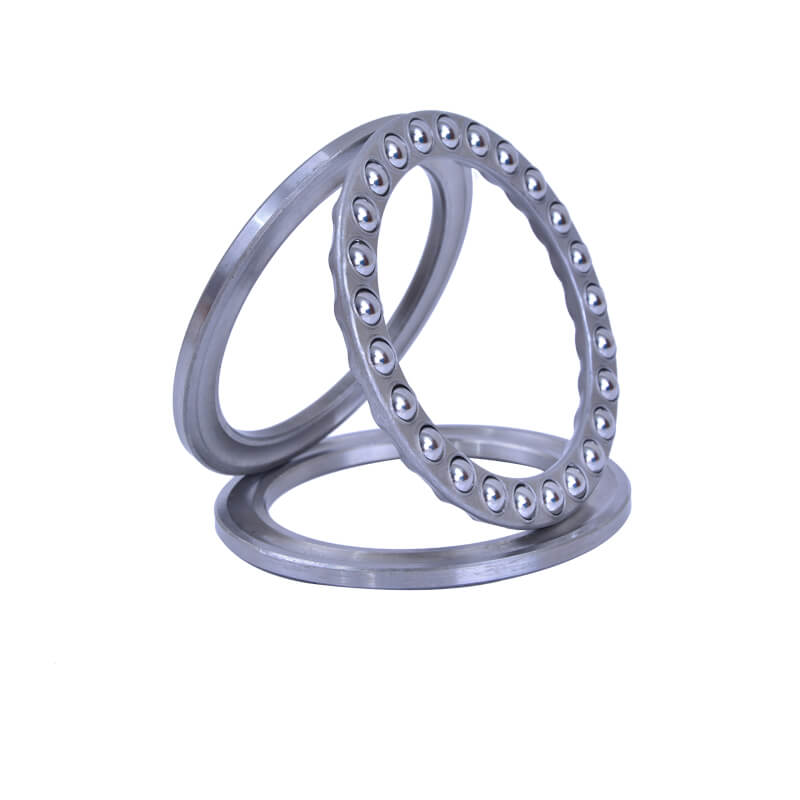

Thrust ball bearing assembly:

There are two key points of

thrust ball bearing assembly. One is to control the pressing quality of cage and steel ball, the other is to control the nominal height T after bearing assembly. In addition, the shaft ring and seat ring can be separated, which brings a management problem. Is to prevent imported bearing parts mixed. The M - type stamping cage uses a curved edge assembly die. After pressing, the steel ball is required to rotate flexibly in the pocket hole, but can not fall off from the pocket hole, and check the channeling momentum of the steel ball in the pocket hole. Too deep embossing of the solid cage will make the ball small momentum, and the connection between the embossing convex part and the cage is too little and the strength is not enough, which is easy to drop the block phenomenon, resulting in the scrapping of the cage. Small thrust ball bearing ring and shaft ring inner diameter size difference is very small, there is no obvious difference between the two groups. In order to prevent the occurrence of mixed sleeve phenomenon, that is, a set of bearings installed into a trapped are seat ring or shaft ring. This requires that certain measures be taken. Usually set with the aid of auxiliary tools will be drawn ring, seat group to be distinguished, or in the sampling of nominal height before checking the diameter of the inner diameter plug gauge, in order to check the diameter of the convenience, the seat ring is put below, the shaft ring is put above. If the inner diameter of the cabinet has obvious quenching heating oxidation color or not through grinding, there is no need to check the inner diameter size, can obviously see the difference between the shaft and the seat ring, not easy to mix the sleeve. After assembling thrust ball bearings, the nominal height T shall be measured and confirmed to be 100 qualified. When measuring, calibrate with height block or standard parts, and measure the load. The bearing needs to be rotated dozens of times, and the minimum height must be reached.

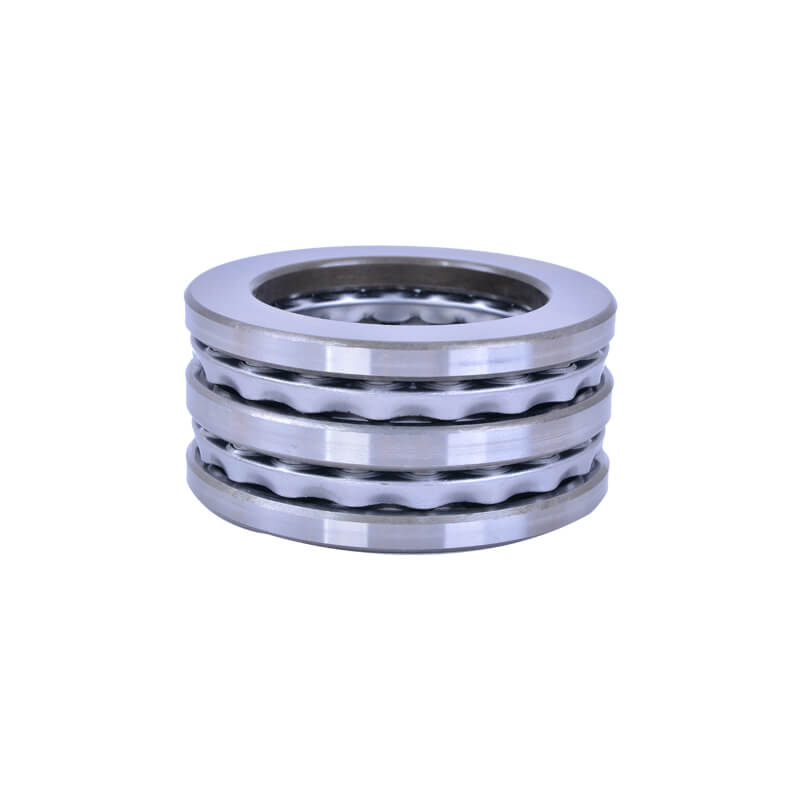

When the thrust ball bearing runs at high speed, the contact Angle between the ball and the radial plane of the raceway will be affected by centrifugal force, resulting in the sliding of the ball relative to the raceway. The adhesive wear caused by this sliding can damage the bearing. To prevent such damage, it is necessary to ensure the minimum load on the thrust ball bearing, as shown in Formula 1 or Formula 2, whichever is greater.

Formula 1: Famin=K • n*n

Formula 2: Famin=Coa/1000

Famin: Minimum axial load (N)

K: minimum axial load coefficient

N: Rotational speed (per minute)

Coa: Basic rated static load (N)

One-way thrust ball bearings can only bear the load in one direction. If they bear the load in two directions, two-way thrust ball bearings must be selected. Thrust ball bearings must apply minimum load or preload. When the shaft is perpendicular, the weight of the shaft usually exceeds the minimum load. At this time, due to the influence of the axial load in the opposite direction, the load of the action may be reduced.