Your washing machine makes a loud grinding noise during the spin cycle. Your ceiling fan wobbles and hums. These common problems often point to one component: a failing bearing. In home appliances, bearings work silently for years until they don’t.

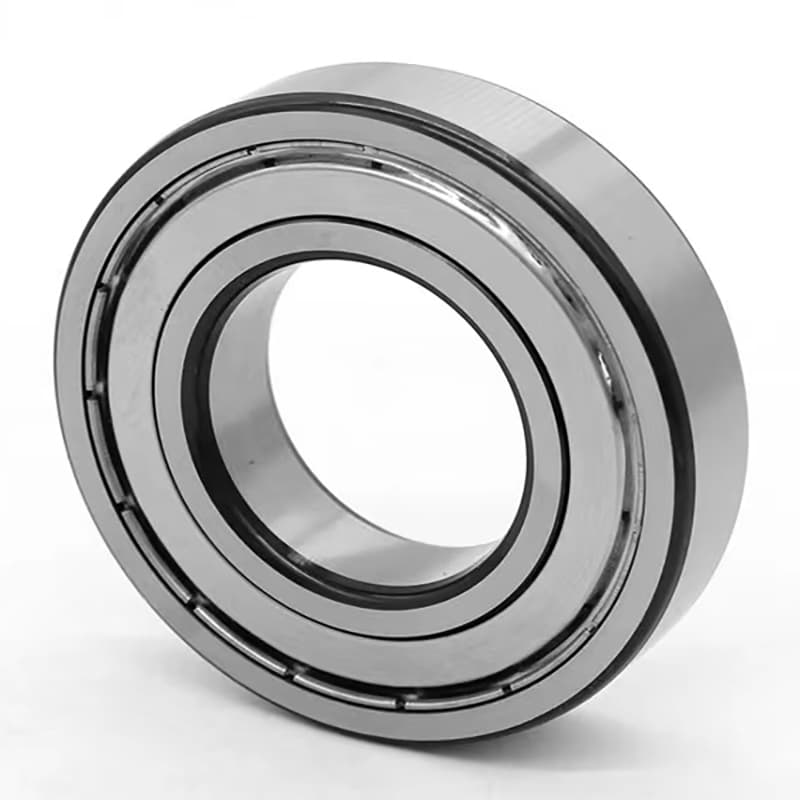

Deep groove ball bearings are the most common bearing in home appliances like washing machines (drum support), fans (motor shaft), and small motors. They provide smooth, quiet rotation, handle moderate loads, and are cost-effective. Their lifespan is challenged by moisture, unbalanced loads, and continuous operation in these appliances.

Appliances demand reliability and quiet operation. A bearing failure means an appliance repair or replacement. Understanding how these bearings work and why they fail is key for manufacturers, repair technicians, and parts distributors. Let’s explore the role of deep groove ball bearings in our everyday machines.

What are the disadvantages of deep groove ball bearings?

Every engineering choice involves a trade-off. Deep groove ball bearings are wonderfully versatile, but they are not invincible. In the specific environment of a home appliance, their inherent weaknesses can be exposed, leading to the failures we experience.

The disadvantages of deep groove ball bearings include limited axial (thrust) load capacity, sensitivity to misalignment, lower radial load capacity compared to roller bearings of similar size, and potential for increased noise if precision is low1 or they become worn. In appliances, these can manifest as premature wear from vibration2 or thrust loads.

How Appliance Stresses Amplify These Disadvantages

Appliance operation is deceptively harsh. What seems like simple spinning often pushes bearings to their design limits.

1. Limited Axial Load Capacity3: The Washing Machine Challenge

- The Disadvantage: They handle moderate axial loads, but are not designed for heavy, continuous thrust.

- Appliance Reality: A top-load washing machine drum, especially when unbalanced, exerts significant axial (side-to-side) forces on the support bearings during the spin cycle.

- The Result: Over time, this thrust wears down the bearing raceway shoulders4, leading to increased play, noise, and eventual failure. Appliance designers often use larger bearings or pair them with thrust washers to mitigate this.

2. Sensitivity to Misalignment5: The Fan and Motor Reality

- The Disadvantage: They require good alignment. Misalignment causes edge loading and rapid wear.

- Appliance Reality: The plastic housings in appliances can warp over time due to heat or stress. A bent fan blade shaft creates dynamic misalignment. A cheaply made motor might have imperfect bearing seats.

- The Result: Even slight misalignment increases friction and heat, accelerating grease breakdown and leading to a noisy, overheating bearing.

3. Load Capacity vs. Size6: The Compact Appliance Dilemma

- The Disadvantage: For a given size, a roller bearing can carry more load.

- Appliance Reality: Appliances are designed to be compact and lightweight. Engineers often choose the smallest possible bearing to save space and cost. This pushes the deep groove ball bearing closer to its load limit, especially during unexpected stress like an overloaded washer.

- The Result: Bearings operating near their limit have a shorter fatigue life7. A sudden shock can cause immediate damage.

For an appliance repair technician or a parts importer like Rajesh, these disadvantages are a diagnostic guide. When a customer complains about a noisy washing machine, understanding these limits points the investigation. Is the drum unbalanced (causing excessive axial load)? Is the shaft bent (causing misalignment)? The table below connects common appliance symptoms to the underlying bearing disadvantage:

| Appliance & Symptom | Likely Exacerbated Bearing Disadvantage | Probable Root Cause |

|---|---|---|

| Washing Machine: Grinding during spin. | Limited Axial Load Capacity3. | Unbalanced drum load creating heavy thrust. |

| Ceiling Fan: Wobble and humming noise. | Sensitivity to Misalignment5. | Bent blade bracket or warped motor housing. |

| Kitchen Blender: Loud whine under load. | Load Capacity vs. Size6 (operating near limit). | Overloading the blender jar. |

| Any Appliance: General bearing rumble after years. | All: General wear from operating at limits. | Normal fatigue accelerated by intermittent high stress. |

At FYTZ, we produce bearings that address these points. For appliance OEMs, we can supply bearings with enhanced axial load capacity8 or tighter precision tolerances to better withstand these common challenges, extending the appliance’s quiet life.

What are the bearings in home appliances?

Open up almost any motorized home appliance. You will find bearings. While deep groove ball bearings1 are the most common, they are not the only type. The specific bearing chosen depends on the load, speed, and cost requirements of that specific component.

The bearings in home appliances are predominantly deep groove ball bearings1, used in motors, fans, and drums. Sleeve (bush) bearings are common in low-cost, low-speed applications like some fan motors. Thrust bearings may be used in washing machines to handle axial load. Needle roller bearings can be found in gearboxes of mixers or food processors.

A Tour of Bearings in a Typical Home

Different appliances and different parts of the same appliance use different bearing solutions. Let’s look at some typical examples.

1. The Champions: Deep Groove Ball Bearings

- Washing Machine & Dryer: Support the heavy rotating drum. Typically two large, sealed bearings (e.g., 6204, 6205 size) in a housing. They must handle water, detergent, and heavy unbalanced loads.

- Refrigerator & AC: In the compressor motor and the condenser/evaporator fan motors. They run continuously and must be very quiet and efficient.

- Ceiling Fan & Table Fan: Support the motor rotor and the blade shaft. They prioritize low noise and long life with minimal maintenance.

- Vacuum Cleaner: In the high-speed motor (often >20,000 RPM). These are critical and must be high-precision to manage heat and vibration.

2. The Cost-Savers: Sleeve (Plain) Bearings

- Where used: In very low-cost appliances, low-speed fan motors (like in some exhaust fans), or in oscillating mechanisms.

- How they work: A shaft rotates in a lubricated brass or bronze bushing. They are cheap but have higher friction, wear out faster, and cannot handle high loads or speeds.

3. The Specialists: Other Bearing Types

- Thrust Bearings: Often used in combination with deep groove bearings in washing machines to specifically handle the axial load of the spinning drum.

- Needle Roller Bearings: Found in the gearboxes of hand mixers or electric can openers, where high radial load needs to be handled in a very compact space.

For a parts distributor, this variety means a diverse inventory is needed. Rajesh’s company, supplying the repair market in India, must stock the common deep groove ball bearings1 for motors (like 6200, 6201, 6202, 6203 series) and also the specific, often larger, sealed units for popular washing machine brands. Knowing which bearings are used where helps forecast demand and provide better service to repair shops.

Is it worth replacing bearings in a washing machine?

This is a practical and economic question every appliance owner and repair shop faces. The answer is not always "yes." It depends on the machine’s age, the cost of the bearings and labor, and the condition of other components.

Replacing washing machine bearings is often worth it if the machine is otherwise in good condition (good motor, electronics, drum) and less than 7-10 years old. The job is labor-intensive and requires special tools, but it can restore the machine to quiet, reliable operation for several more years, which is usually cheaper than buying a new machine.

The Cost-Benefit Analysis of a Bearing Replacement

This is a classic repair vs. replace decision. Let’s break down the factors that tip the scale.

1. The Case FOR Replacement:

- Cost-Effective1: A set of quality replacement bearings (like those from FYTZ) might cost $20-$40. Even with labor, the total is often a fraction of a new washing machine.

- Extends Appliance Life2: A machine with a solid motor, good controls, and no leaks can easily run for 5-10 more years after a bearing replacement.

- Environmental Choice3: Repairing is more sustainable than discarding a large appliance.

- Symptom Clarity: If the only problem is a loud grinding/rumbling during spin, it’s almost certainly the bearings (and often the seal that failed first, allowing water in).

2. The Case AGAINST Replacement:

- Labor Intensity4: Replacing drum bearings is one of the most complex appliance repairs. It often requires disassembling the entire machine, which is time-consuming.

- Risk of Secondary Damage5: If the bearings have been failing for a while, they may have damaged the drum shaft or the bearing housing (tub). Replacing bearings in a scored housing is a temporary fix.

- Age of the Appliance: If the machine is over 10-12 years old, other expensive components (like the transmission in some models, the motor, or the electronic control board) are also near the end of their life. Investing in bearings might be followed by another costly repair soon.

- Availability of Parts6: For some older or obscure brands, finding the exact bearing and seal kit can be difficult.

3. The Distributor’s and Technician’s Role:

For Rajesh’s business, this question represents an opportunity. They supply both the bearings and the knowledge.

- For Repair Shops: They can provide high-quality, reliable bearing and seal kits. A bearing that fails quickly after a difficult repair destroys the shop’s reputation. Supplying durable FYTZ bearings protects that.

- For DIYers (a smaller market): They can sell the kit with clear warnings about the complexity.

The decision often comes down to this rule of thumb: If the repair cost (parts + labor) is less than 50% of the price of a comparable new appliance, and the machine isn’t very old, repairing is usually worthwhile. Providing this context helps customers make informed decisions.

What are the advantages of deep groove ball bearings1?

Despite their disadvantages, deep groove ball bearings1 are everywhere for a reason. Their advantages perfectly match the core needs of mass-produced, cost-sensitive, and performance-driven products like home appliances.

The key advantages of deep groove ball bearings1 are their ability to handle both radial and moderate axial loads, their high-speed capability2 with low friction3, their simple and compact design4 for easy installation, their relatively low cost due to mass production, and their potential for very quiet operation5 when manufactured to high precision.

Why Appliance Designers Love Deep Groove Ball Bearings

These advantages are not abstract; they translate directly into benefits for the appliance manufacturer and the end-user.

1. Versatility in Load Handling (The "Two-for-One" Benefit)

An appliance motor shaft experiences radial load from the rotor weight and often some axial load from magnetic forces or attached components. A deep groove ball bearing handles both without needing an additional thrust bearing. This simplifies design, reduces part count, and saves space and cost.

2. High-Speed and Low-Friction Operation (The Efficiency Benefit)

- High Speed: They can easily handle the speeds of appliance motors (from a few hundred RPM in a washer drum to tens of thousands in a vacuum cleaner).

- Low Friction: Rolling friction is much lower than the sliding friction of a sleeve bearing. This means less energy is wasted as heat, making the appliance more efficient and cooler running. This is critical for meeting modern energy standards.

3. Simple and Robust Design (The Reliability & Cost Benefit)

- Easy to Manufacture: The design is symmetrical and well-understood, allowing for high-volume, consistent production at low cost.

- Easy to Install: They are non-separable but can be pressed onto a shaft easily. Pre-lubricated and sealed versions are "fit and forget" components for assembly lines.

- Robust: With proper seals, they keep grease in and contaminants out, leading to long, maintenance-free life6—a must for sealed appliances.

4. Quiet Operation (The User Experience Benefit)

When manufactured to good precision standards (like the P6 class FYTZ offers), deep groove ball bearings1 run very smoothly and quietly. Noise is a key quality indicator for appliances like refrigerators, fans, and washing machines. A quiet bearing is a happy customer.

For an appliance OEM, these advantages are compelling. They allow the designer to create a reliable, efficient, quiet, and affordable product. For a bearing manufacturer like FYTZ, serving this market means mastering high-volume production of consistent quality. We must deliver bearings that are cost-competitive7 (advantage #3) but also quiet and reliable (advantage #4) to meet our clients’ brand standards. The table below summarizes this value proposition:

| Appliance Design Goal | How Deep Groove Ball Bearings Help Achieve It | FYTZ’s Role |

|---|---|---|

| Cost-Effective Production | Simple, mass-producible design. | Provide consistent quality at competitive OEM pricing. |

| Energy Efficiency | Low rolling friction. | Ensure smooth, low-torque operation. |

| Quiet Operation | Potential for high-precision, smooth running. | Manufacture to P6/P5 precision grades for low-noise models. |

| Long, Maintenance-Free Life | Robust, sealed design. | Use effective seal designs and long-life grease. |

| Compact Design | Single unit handles combined loads. | Offer a wide range of sizes (miniature to medium) to fit any space. |

This synergy between the bearing’s inherent advantages and the appliance industry’s needs is why deep groove ball bearings1 will remain the heart of home appliance rotation for the foreseeable future.

Conclusion

Deep groove ball bearings are the unsung heroes of home appliances, enabling smooth, quiet, and efficient operation. Understanding their advantages, limitations, and common failure modes is essential for designing reliable products, executing successful repairs, and supplying the right parts to the global market.

-

Explore this link to understand the fundamental role of deep groove ball bearings in various applications. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the high-speed capabilities of these bearings and how they enhance appliance performance. ↩ ↩ ↩

-

Discover how low friction contributes to energy efficiency in appliances, making them more effective. ↩ ↩ ↩ ↩

-

Find out why a simple and compact design is crucial for manufacturing and installation in appliances. ↩ ↩ ↩

-

Investigate the factors that lead to quiet operation in deep groove ball bearings, enhancing user experience. ↩ ↩ ↩ ↩

-

Understand the design features that allow these bearings to operate maintenance-free for extended periods. ↩ ↩ ↩ ↩

-

Explore the reasons behind the cost-competitive nature of these bearings in the appliance industry. ↩ ↩

-

Exploring this can reveal how advanced bearing designs can improve appliance reliability and performance. ↩