The hum of a motor should be smooth. The flow of air from a fan should be steady. But what if you hear a persistent whine, a troubling rumble, or feel excessive vibration? Often, the source is not the motor or fan itself, but its support system: the pillow block bearing.

Pillow block bearings for motors and fans must minimize vibration and noise. This requires precision bearings (like P6 class), proper internal clearance, high-quality lubrication, and correct installation. A quiet, smooth-running bearing extends equipment life and improves overall system efficiency.

Noise and vibration are more than just nuisances. They are energy loss and early failure in action. For critical equipment like HVAC systems, industrial fans, and pump motors, controlling them is essential. Understanding the role of pillow block bearings in this control is the first step to a quieter, more reliable operation.

What are pillow block bearings used for?

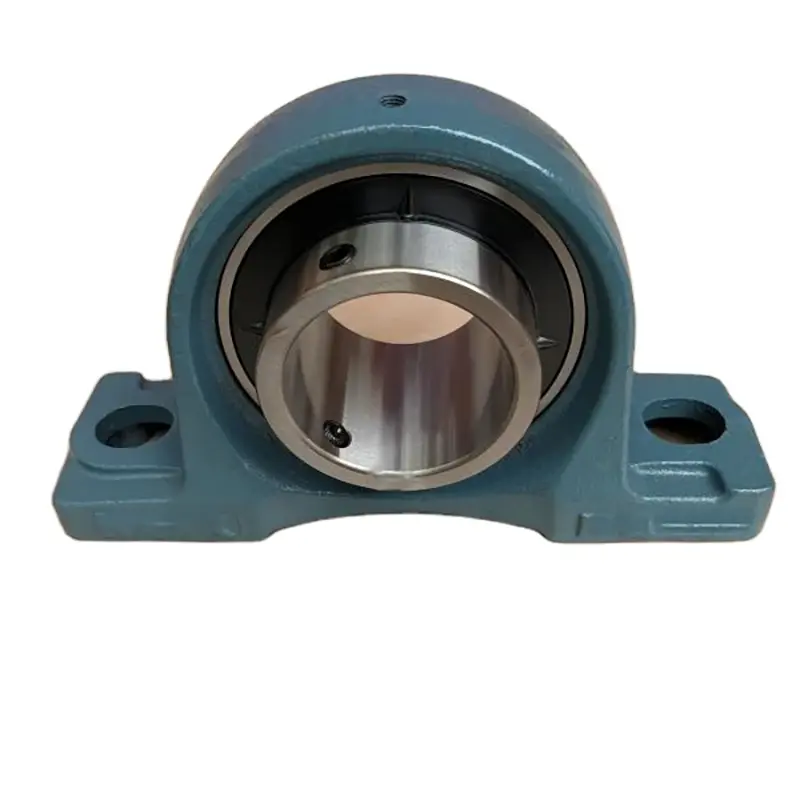

You see them everywhere in industry: those sturdy blocks bolted to a frame, holding a rotating shaft. They are not just holders. They are the critical link between a spinning shaft and a stationary machine. Their job determines the machine’s health.

Pillow block bearings1 are used to support a rotating shaft and its attached components (like pulleys, fans, or gears) in a fixed location. They provide secure mounting, accommodate some misalignment, protect the bearing from contamination, and simplify installation and maintenance across countless industrial machines.

The Pillow Block as a System Integration Component

A pillow block is more than a bearing in a box. It is a pre-assembled, ready-to-install module that solves multiple engineering challenges at once. For motors and fans, its specific uses are vital for performance.

1. Primary Function: Shaft Support and Load Management2

The core bearing inside (ball, spherical, etc.) carries the load. The pillow block housing transfers that load securely to the machine frame. For a fan, this means handling the weight of the shaft and impeller, plus any dynamic forces from imbalance or airflow.

2. Critical Function for Motors/Fans: Alignment and Misalignment Accommodation3

Perfect, permanent alignment between a motor and a driven fan or pump is rare. Thermal expansion, frame settling, and belt tension all cause small shifts.

- Self-Aligning Types: Many pillow blocks use spherical roller bearings or ball bearings with spherical outer surfaces. These allow the bearing inside to pivot slightly within the housing, compensating for angular misalignment of the shaft. This prevents binding and excessive load on the bearing.

3. Essential Function: Sealing and Protection4

Industrial environments are dirty. Dust, moisture, and chemicals can kill a bearing. Pillow blocks come with integrated seals (rubber, labyrinth) that protect the bearing’s lubricant and keep contaminants out. This is crucial for long life.

4. Practical Function: Ease of Installation and Maintenance5

The split design of many pillow blocks (like UCP) allows them to be installed onto a shaft without needing to slide the bearing over shaft ends. This is a huge advantage for maintenance. They also typically have grease fittings for easy relubrication.

For an equipment manufacturer or maintenance provider, choosing the right pillow block is a design decision. The table below shows how function dictates selection for typical motor/fan applications:

| Application | Primary Load & Challenge | Recommended Pillow Block Type | Key Functional Reason |

|---|---|---|---|

| Small Electric Motor (up to 10kW) | Light radial load, high speed, need for low noise. | UCP 200 Series6 (Ball Bearing) with rubber seals. | Ball bearings run quietly at high speed. Standardized, cost-effective. |

| Industrial Centrifugal Fan | Moderate to heavy radial load, potential for shaft misalignment, dirty environment. | UKP 200 Series7 (Spherical Roller Bearing) with labyrinth seals. | Spherical roller handles misalignment and heavier loads. Better sealing. |

| Belt-Driven Blower | Combined radial (belt tension) and light axial load. | UCP with Tapered Roller Bearing (if axial load is significant). | Tapered rollers handle combined loads effectively. |

| Large HVAC Fan (Low Speed) | Heavy load, emphasis on long life with minimal maintenance. | Heavy-Duty Split Housing8 with Spherical Roller Bearing. | Robust design for load, easy maintenance access. |

At FYTZ, we produce a range of pillow blocks for these exact scenarios. For a distributor like Rajesh’s company, this functional understanding helps them match our products to their customer’s needs in Indonesia’s manufacturing plants or South Africa’s mining operations, ensuring the bearing supports the machine’s function perfectly.

What is the difference between UCP and UKP?

In a parts catalog, you see UCP 205 and UKP 205. They look similar, maybe even have the same bolt holes. But using a UCP where you need a UKP is a common mistake that leads to premature failure. The letters define a critical internal difference.

UCP denotes a pillow block with a ball bearing insert (typically 62 series, like 6205). UKP denotes a pillow block with a spherical roller bearing insert1 (typically 22 series, like 22205). This fundamental difference determines their load capacity2, misalignment tolerance3, and suitable applications.

Choosing Between a Sprinter and a Weightlifter

The "P" stands for "Pillow Block." The "UC" and "UK" define the athlete inside. You wouldn’t ask a sprinter to lift a heavy barbell, or a weightlifter to run a marathon. The same logic applies here.

UCP Series: The Precision Sprinter (Ball Bearing)

- Internal Bearing: Deep Groove Ball Bearing (e.g., 6205).

- Key Traits:

- Lower Radial Load Capacity: Compared to a same-size spherical roller bearing.

- Higher Speed Capability: Can run at very high RPMs smoothly.

- Minimal Misalignment Tolerance: Ball bearings do not self-align well. They rely on precise shaft alignment.

- Lower Cost: Generally more economical.

- Best For: Applications with high speed, light to moderate radial loads, and precise alignment. Examples: small electric motors, conveyor tail pulleys, light-duty fans.

UKP Series: The Robust Weightlifter (Spherical Roller Bearing)

- Internal Bearing: Spherical Roller Bearing (e.g., 22205).

- Key Traits:

- Very High Radial Load Capacity: Can handle 2-3 times the load of a same-size ball bearing.

- Good Misalignment Tolerance: The spherical rollers allow the bearing to accommodate 1-3 degrees of angular misalignment. This is a critical advantage.

- Moderate Speed Capability: Suitable for most industrial speeds, but not for extremely high RPMs like a ball bearing.

- Higher Cost: Due to a more complex bearing.

- Best For: Applications with heavy radial loads4, shock loads, and expected shaft misalignment. Examples: large industrial fans, heavy conveyors, gearboxes, vibrating screens.

Why the Confusion Happens:

They often share the same numbering system (e.g., 205, 206) which refers to the shaft diameter (in millimeters divided by 5). A UCP 205 fits a 25mm shaft. A UKP 205 also fits a 25mm shaft. The housings have similar footprints. This makes them seem interchangeable, but they are not.

For a procurement manager like Rajesh, this distinction is business-critical. If a customer in Brazil orders a "205 pillow block" for a heavy fan, supplying a UCP 205 could lead to a rapid failure and a damaged relationship. Knowing to ask about the load and application allows Rajesh to recommend and supply the correct UKP 205 from FYTZ’s catalog. This technical knowledge builds trust and prevents costly errors.

What is a 6203 bearing1 used for?

The 6203 is one of the most common bearings in the world. You will find it in everything from small appliances to industrial gearboxes. When it’s inside a pillow block, it usually defines a UCP 2032 unit. Its popularity comes from its versatile size and performance.

A 6203 bearing1 is a deep groove ball bearing3 with a 17mm bore, 40mm OD, and 12mm width. It is used for light to moderate radial loads at high speeds. Common applications include small electric motors (fans, pumps), skateboards, agricultural equipment spindles, and as the insert in UCP 2032 pillow blocks.

The Workhorse of Small Power Transmission

The 6203 is a standard component in the engineer’s toolkit. Its specifications make it suitable for a vast range of applications where size, cost, and performance must balance.

1. Specification Breakdown:

- Bore: 17 mm (Common shaft size)

- Outside Diameter: 40 mm

- Width: 12 mm

- Dynamic Load Rating (C)4: Approximately 10 kN (varies by manufacturer)

- Speed Rating: Can often exceed 10,000 rpm with proper lubrication.

2. Typical Applications in Detail:

- Small AC/DC Electric Motors: This is the premier application. Motors in the fractional to 1 horsepower range often use 6203 bearing1s on both ends of the rotor shaft. They provide smooth, low-friction support for high rotational speeds.

- Pillow Block Bearings: As the core of a UCP 2032 or UCF 203 (flange block), it creates a compact, ready-to-mount shaft support for light-duty conveyors, fan shafts, and machinery.

- Automotive Accessories: Alternators, water pumps, and idler pulleys may use 6203-sized bearings.

- Agricultural and Garden Equipment: In lawnmower blade spindles, tiller rotors, and small implement wheels.

- Consumer Products: From industrial blowers to washing machine drums and even high-performance skateboard wheels.

3. Why it’s Chosen for Motor/Fan Noise Control:

For noise-sensitive applications, the 6203, when manufactured to a P6 or even P5 precision class5, offers significant advantages:

- Geometric Accuracy: The raceways and balls are more perfectly round and smooth. This reduces vibration caused by geometric imperfections.

- Surface Finish: A superior surface finish on rolling elements minimizes friction and the resulting noise.

- Consistent Clearance: Tighter control over internal radial clearance ensures smooth operation without slop or preload.

At FYTZ Bearing, we produce 6203 bearing1s in standard and precision grades. For our distributors supplying the repair market, this is a high-volume item. When Rajesh’s company supplies a local motor repair shop6 in Mumbai, providing FYTZ 6203 bearing1s with consistent quality and good noise performance means the repaired motor runs quietly and reliably. This builds a repeat business stream based on product performance, not just price.

What are the common problems with pillow blocks?

A pillow block fails. The immediate reaction is to blame the bearing inside. But often, the root cause is external. The pillow block system amplifies or creates problems that a bare bearing might not face. I see these patterns repeatedly.

Common pillow block problems include lubrication failure (dry or contaminated grease), seal damage allowing dirt ingress, improper installation (misalignment, incorrect fit), housing wear from loose bolts, and bearing creep (rotation in housing) due to poor fit or excessive load.

Diagnosing System Failures, Not Just Component Failures

A pillow block is a system. Failure analysis must consider all interacting parts: housing, bearing, seal, lubricant, shaft, and frame. Let’s categorize the common problems from a system perspective.

1. Lubrication-Related Problems (The Most Common)

- Grease Degradation: The grease oxidizes from heat, hardens, or separates. The bearing runs dry.

- Over-greasing: Especially in high-speed applications, overfilling causes churning and overheating.

- Contaminated Grease1: Dirt enters through damaged seals or during greasing, acting as an abrasive.

2. Installation and Mounting Problems

- Shaft Misalignment2: Even self-aligning types have limits. Severe misalignment causes edge loading, heat, and noise. This is often due to a poorly aligned frame or a bent shaft.

- Incorrect Fit: A loose fit on the shaft causes creep and fretting wear. A tight fit on the outer ring in the housing can distort the bearing, removing internal clearance.

- Improper Locking: A set screw not tightened on the shaft flat, or an eccentric collar not properly engaged, allows the bearing to spin on the shaft.

3. Seal and Contamination Problems

- Seal Damage3: Rubber lip seals can tear during installation or degrade from heat/chemicals. Labyrinth seals can get packed with solid material.

- Ingress of Contaminants: Water, dust, or process material (flour, cement) gets in, leading to abrasive wear and corrosion.

4. Housing and Frame Problems

- Loose Mounting Bolts4: Vibration causes bolts to loosen, allowing the entire unit to move, which destroys alignment.

- Housing Bore Wear5: If the bearing outer ring rotates in the housing (due to loose fit or heavy load), it wears the housing bore, creating even more looseness.

- Frame Resonance6: Sometimes, the natural vibration frequency of the support frame amplifies bearing vibration, creating excessive noise.

For maintenance teams and bearing suppliers, a structured troubleshooting approach is key. The table below links symptoms to likely system-level problems:

| Symptom Observed | Possible Pillow Block System Problem | Investigation & Action |

|---|---|---|

| High Temperature | Over-greasing; Misalignment; Dry grease; Excessive load. | Check grease amount/condition; Check alignment; Verify load. |

| Excessive Noise/Vibration | Bearing damage (from contamination); Misalignment; Loose fit; Unbalanced shaft. | Inspect bearing; Check alignment and fits; Balance rotor. |

| Grease Leakage | Over-greasing; Damaged seal; Wrong grease type (too soft). | Clean relief port; Inspect/replace seal; Use correct grease. |

| Bearing Creep7 (outer ring turns) | Loose housing fit; Excessive load; Housing bore wear. | Measure housing bore; Check load; Repair housing or use adhesive. |

Understanding these system problems allows FYTZ and our distributors to provide complete solutions. When Rajesh’s customer in Vietnam reports a failed UKP block, the conversation can move beyond "send a new one." They can ask about mounting practices and seals. This helps the customer fix the root cause, ensuring the replacement FYTZ bearing lasts its full design life, cementing a reputation for reliability and support.

Conclusion

For electric motors and fans, the right pillow block bearing is a strategic choice for noise and vibration control. Selecting the correct type (UCP vs. UKP), ensuring precision, and avoiding common installation pitfalls are the keys to smooth, quiet, and long-lasting operation.

-

Contaminated grease can severely affect performance; understanding this can help in selecting the right maintenance practices. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learning about shaft misalignment can improve installation practices and enhance the longevity of your equipment. ↩ ↩ ↩ ↩ ↩ ↩

-

Exploring seal damage can help you identify potential issues before they lead to significant failures. ↩ ↩ ↩ ↩

-

Understanding the risks of loose mounting bolts can help in maintaining proper alignment and reducing vibration issues. ↩ ↩ ↩ ↩

-

Recognizing housing bore wear can lead to better maintenance strategies and prevent premature bearing failures. ↩ ↩ ↩

-

Exploring frame resonance can lead to better design choices and improved operational efficiency in machinery. ↩ ↩ ↩

-

Preventing bearing creep is essential for ensuring the stability and reliability of your pillow block systems. ↩ ↩

-

Learn about the robust design of heavy-duty split housing and its impact on maintenance and load handling. ↩