Classification application:

Thrust bearings are divided into thrust ball bearings and thrust roller bearings.

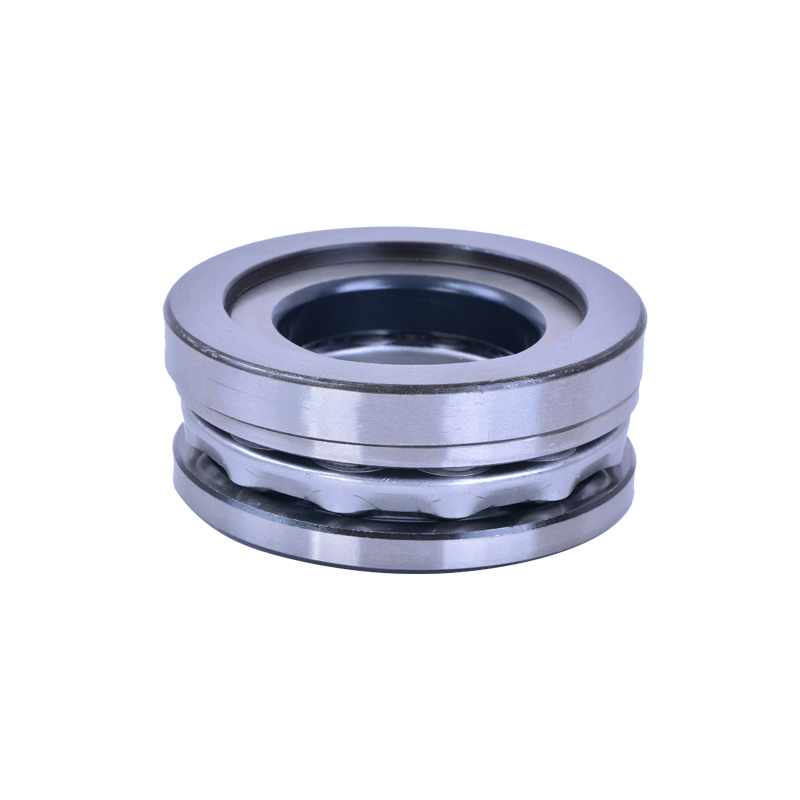

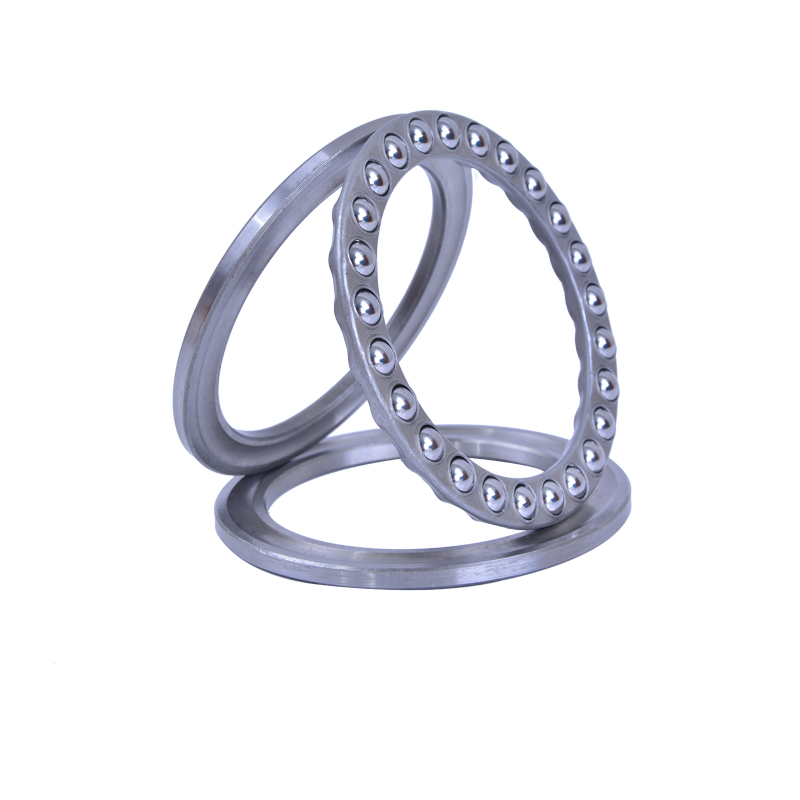

Thrust ball bearings are divided into thrust ball bearings and thrust angular contact ball bearings. A raceway ring with a raceway gasket and a ball and a cage assembly is called a raceway ring with a shaft, and a raceway ring with a housing is called a seat ring. Two-way bearings match the center ring with the shaft. Unidirectional bearing can bear unidirectional axial load, and bidirectional bearing can bear bidirectional axial load. The bearing with spherical mounting surface of the seat ring has self-aligning performance, which can reduce the influence of installation error. This kind of bearing is mainly used in automobile steering mechanism, machine tool spindle.

Thrust roller bearings are divided into thrust cylindrical roller bearings, thrust self-alting roller bearings, thrust tapered roller bearings, thrust needle roller bearings.

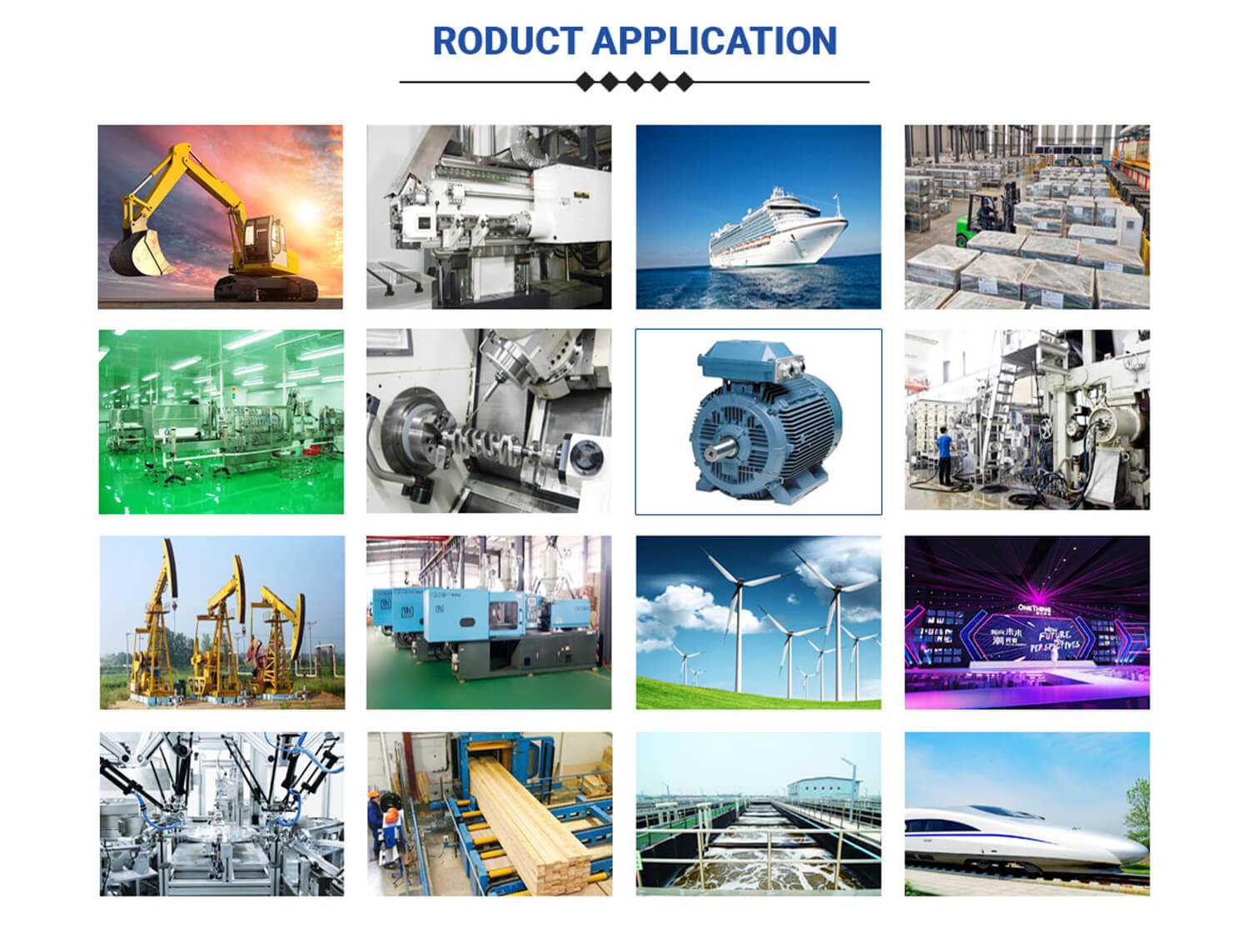

Thrust cylindrical roller bearings are mainly used in oil drilling RIGS, iron and steel machinery.

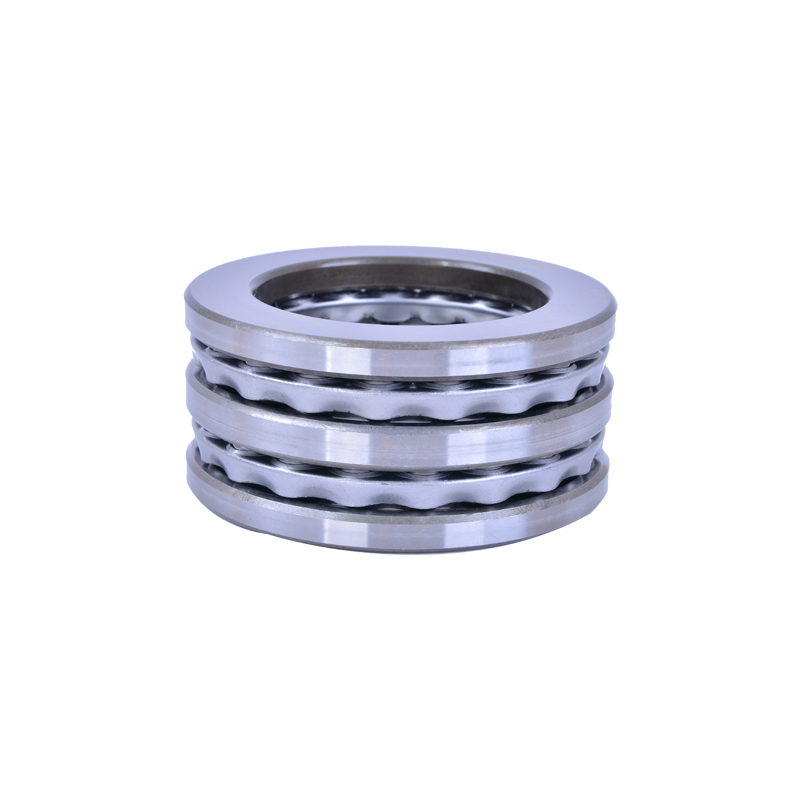

This kind of thrust self-aligning roller bearing is mainly used in hydraulic generator, vertical motor, ship propeller shaft, tower crane, extruder and so on.

Thrust tapered roller bearing this kind of bearing main uses: one-way: crane hook, oil drilling ring. Two-way: roll neck of rolling mill.

Planar thrust bearing is mainly subjected to axial load in assembly and is widely used. Although the installation and operation of thrust bearings are relatively simple, errors often occur in actual maintenance, that is, the installation position of the tight ring and loose ring of the bearings is not correct, which results in the loss of the bearing and the journal is quickly worn out. The tight ring is installed on the end face of the stationary part, that is, wrong assembly. The inner ring of the tight ring is a transition fit with the shaft journal. When the shaft rotates, the tight ring is driven and friction occurs with the end face of the stationary part. When the axial force (Fx) is applied, the friction torque is greater than the resistance moment of the inner diameter fit, resulting in forced rotation of the tight ring and the shaft mating surface, which intensifies the wear of the shaft journal.