A conveyor in a copper mine stops. A crusher in a quarry jams. Downtime costs thousands per hour. At the heart of these brutal machines, pillow block bearings face a constant war against dirt, shock, and massive loads. Standard industrial units simply won’t survive.

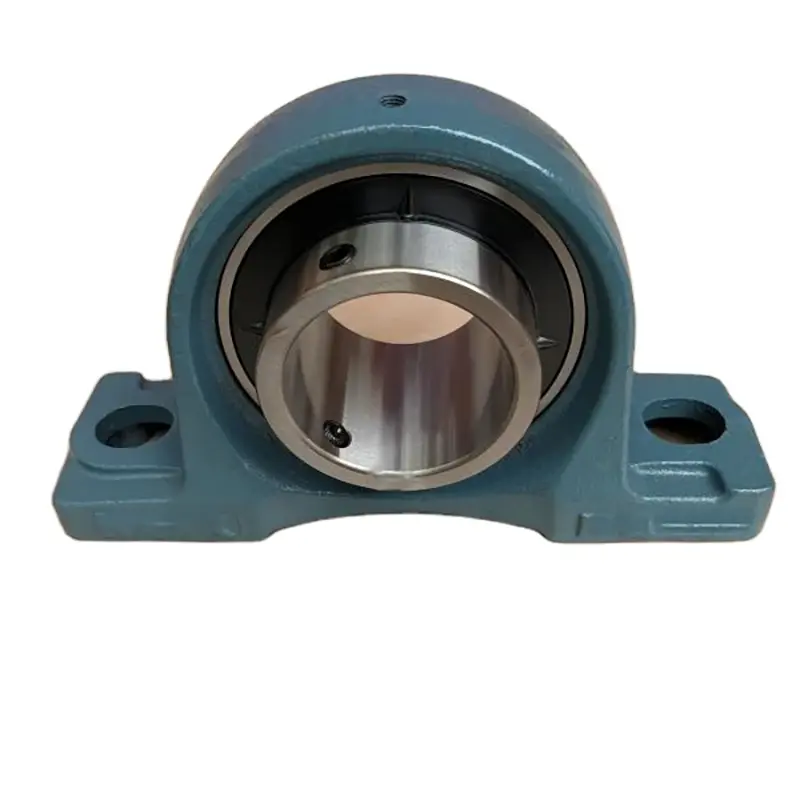

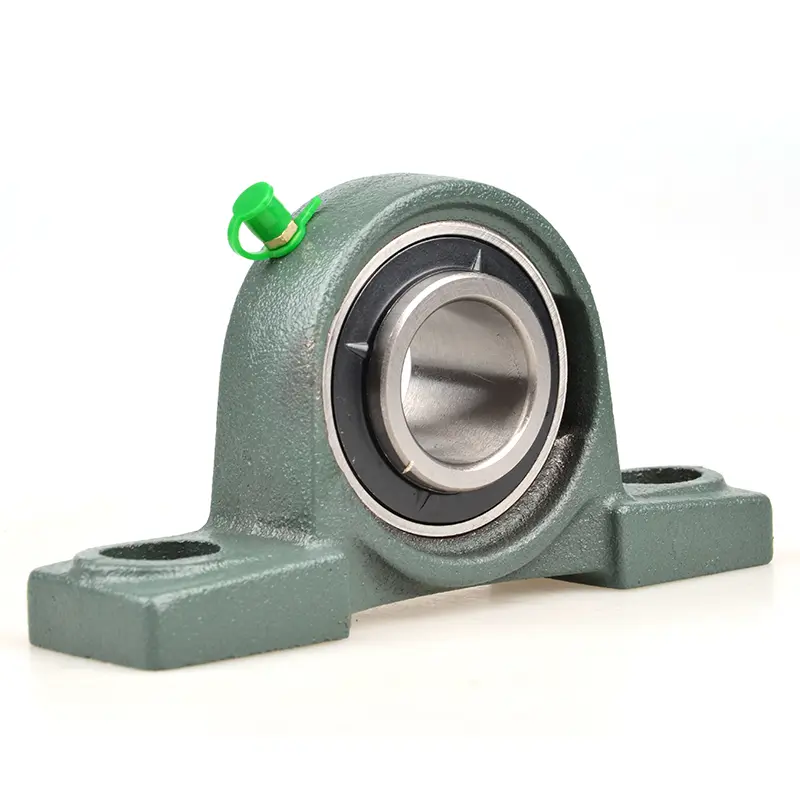

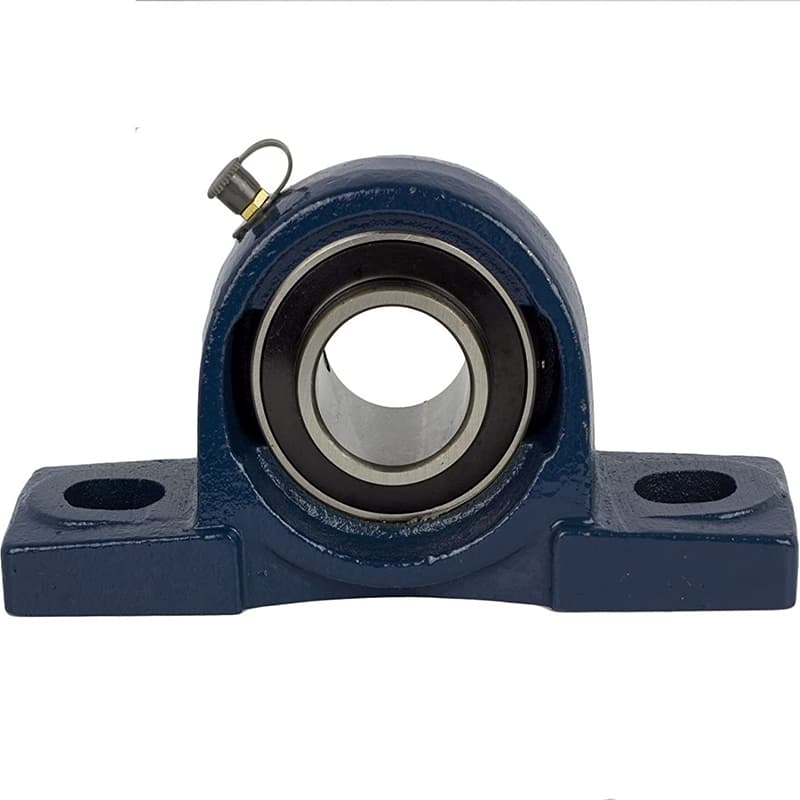

Pillow block bearings for mining and quarry equipment are heavy-duty units designed to withstand extreme radial and axial shock loads, severe contamination (dust, water, slurry), and significant misalignment. They feature robust housings (often ductile iron or cast steel), premium spherical roller bearing inserts, advanced sealing systems, and often specialized lubrication for the harshest environments.

This isn’t just about picking a bearing from a catalog. It’s about selecting a survival system engineered for an environment that eats standard components for breakfast. For equipment owners, OEMs, and parts distributors, understanding this specialization is the key to reliability. Let’s examine what makes a mining-grade pillow block.

What are pillow block bearings used for?

In mining and quarrying1, pillow block bearings are not just supports; they are the critical pivot points that enable movement under unimaginable stress. They are the workhorses that allow massive, heavy, and dirty systems to rotate reliably day after day.

In mining and quarry equipment, pillow block bearings are used to support rotating shafts on conveyors (head, tail, and bend pulleys), crushers and screens, vibrating feeders, stackers and reclaimers, and fan and pump drives. They provide secure mounting, carry immense loads, and protect the bearing from the abrasive, wet environment.

The Specific, Demanding Roles in a Mine or Quarry

Each application subjects the pillow block to a unique combination of abuse. Let’s break down their primary battlefield roles.

1. Conveyor Systems: The Backbone of Material Movement

This is the most common application. Pillow blocks support every pulley.

- Head/Tail Pulleys: Experience high belt tension (radial load) and some misalignment. They are exposed to falling material and dust.

- Bend/Take-up Pulleys: Must accommodate shaft movement as the tensioning system operates, requiring bearings that allow axial shift or using units designed for this.

2. Crushing and Screening Equipment: The Shock and Vibration Zone

- Crusher Drives: Bearings here face extreme shock loads from rocks being crushed. The loads are not smooth; they are sudden, hammer-like impacts.

- Vibrating Screens and Feeders: These units impose continuous, high-frequency vibration on the bearings. Standard bearings can suffer from "false brinelling" where the rollers fret in the raceways without rotating.

3. Heavy-Duty Fans and Pumps: The High-Speed, Contaminated Challenge

Fans for ventilation and pumps for slurry handling run at higher speeds. Their bearings must handle both the dynamic load and the ingress of fine, abrasive dust or corrosive slurry.

For an equipment designer or a maintenance planner, the application dictates the specification. The table below summarizes the brutal demands:

| Mining Equipment | Primary Bearing Function | Extreme Challenges Faced |

|---|---|---|

| Conveyor Pulley | Support shaft under high belt tension. | Continuous radial load, dust and moisture ingress, potential for misalignment. |

| Jaw Crusher | Support the eccentric shaft. | Extreme shock loads, contamination from rock dust. |

| Vibrating Screen | Allow the box to vibrate freely. | Continuous high-frequency vibration, exposure to abrasive material. |

| Slurry Pump | Support the impeller shaft. | Combined radial/thrust loads, abrasive/corrosive slurry contamination, higher speeds. |

At FYTZ, we don’t just see a "pillow block." We see an application. When a mining OEM in South Africa or a quarry operator in Indonesia needs a solution, we specify the housing material, bearing type, seal, and lubrication specifically for that punishing role. This application-focused approach2 is what separates a generic part from a heavy-duty solution.

How much weight can a pillow block bearing hold?

This is the most frequent question, but it’s incomplete. "Weight" implies a static radial load. In mining, the load is dynamic, shocking, and often combined with thrust. The answer is not a single number but a capacity profile defined by the internal bearing’s dynamic load rating (C)1 and the housing’s strength.

The weight a pillow block can hold is determined by the dynamic load rating (C)1 of its internal bearing insert (e.g., a spherical roller bearing2). For heavy-duty mining blocks with spherical rollers, this rating can range from 200 kN to over 2000 kN (20 to 200+ metric tons of dynamic load capacity). The static load capacity (Co) is even higher for shock loads.

Understanding Load Ratings in the Context of Mining Abuse

The catalog C value is a starting point. In mining, you must de-rate it for the harsh conditions and consider the system’s ability to handle shock.

1. The Core: Internal Bearing Load Rating

The capacity comes from the rolling element inside. For mining, this is almost always a spherical roller bearing2.

- Dynamic Load Rating (C): The load at which the bearing will achieve an L10 life of 1 million revolutions. This is the key rating for continuously rotating equipment like conveyors.

- Static Load Rating (Co): The maximum load the bearing can withstand without permanent deformation while stationary. This is critical for shock loads in crushers.

2. The Housing’s Role: It Must Be Strong Enough

A high-capacity bearing in a weak housing is useless. Mining pillow blocks use:

- Ductile Iron (Grade 500-700)3: Stronger and more shock-resistant than standard gray cast iron.

- Cast Steel: For the most severe applications with massive shock loads.

The housing must be designed with sufficient wall thickness and robust base geometry to transfer the load to the frame without flexing or cracking.

3. The Reality of Mining Loads: De-Rating for Conditions

The catalog C rating assumes clean, well-lubricated, aligned conditions. In a mine, you must apply severe adjustment factors:

- Contamination Factor: Dust and grit in the bearing drastically reduce life. Effective sealing is part of the "capacity" solution.

- Shock Load Factor: For crushers, engineers often select a bearing with a static load rating (Co)4 at least 4-5 times the expected peak shock load to prevent brinelling.

Practical Load Selection Guide:

For a distributor like Rajesh’s company, helping a customer select a block involves understanding the real load. Here’s a simplified approach:

| Application (Example) | Load Type | Key Rating to Consider | Selection Advice |

|---|---|---|---|

| Conveyor Tail Pulley | Steady radial load from belt tension. | Dynamic (C). Ensure C is sufficiently high for desired L10 life. | Choose a standard heavy-duty block (e.g., FYTZ series with 222 spherical roller). |

| Jaw Crusher Eccentric | Extreme shock loads. | Static (Co). Co must be several times the estimated shock force. | Choose a block with a high-Co bearing (maybe 223 or 230 series) in a cast steel housing. |

| Vibrating Screen | High cyclic load from vibration. | Dynamic (C) and bearing’s resistance to fretting. | Select a bearing with internal preload or special clearance to prevent false brinelling. |

When FYTZ supplies mining-grade pillow blocks, we provide these load ratings transparently. We help our partners understand that for a 150-ton shock load in a crusher, you need a block with a Co rating of 600+ kN, not just a block that "fits the shaft." This technical support ensures the solution works, protecting the end-user’s operation and the distributor’s reputation.

What are the common problems with pillow blocks?

In the gentle world of mining, "common problems" are often catastrophic failures. Understanding these failure modes is the first step to specifying a block that can resist them. The problems in mining are amplified versions of industrial issues.

Common problems with pillow blocks in mining include seal failure leading to abrasive contamination1, housing fracture from shock loads2, bearing inner ring creep on the shaft3, lubrication wash-out or contamination4, and false brinelling on vibrating equipment5. These failures are directly linked to the extreme environment and loads.

Diagnosing and Designing Out Failure in Harsh Environments

Each problem points to a specification requirement. Your choice of pillow block must proactively address these points.

1. Seal Failure & Contamination: The #1 Killer

Dust and slurry are abrasive. Once inside, they grind down the bearing surfaces.

- The Solution: Standard lip seals fail. Mining blocks need multi-stage labyrinth seals6 or PTFE (Teflon) seals that create a complex, tortuous path for contaminants. Some designs include grease purge ports to actively push dirt out.

2. Housing Fracture

Gray cast iron is brittle. A massive rock impact on a crusier can crack it.

- The Solution: Specify ductile iron or cast steel housings. These materials absorb shock without cracking.

3. Bearing Creep (Rotation on the Shaft)

Under heavy load and vibration, the bearing’s inner ring can slowly rotate on the shaft, causing fretting wear that destroys both the shaft and the bearing fit.

- The Solution: Ensure a proper interference fit. For extreme cases, use pillow blocks with adapter sleeves (like SAF blocks) that provide a more uniform and secure clamping force than a simple set screw.

4. Lubrication Problems

Water can wash out grease. High temperatures can bake it solid.

- The Solution: Use high-temperature, water-resistant synthetic grease as a standard fill. For critical, high-speed applications, specify blocks prepared for automatic centralized lubrication systems.

5. False Brinelling on Vibrating Equipment

On screens, the bearing oscillates slightly without full rotation. This causes wear patterns in the raceways.

- The Solution: Use bearings with special internal clearance or preload designed for vibrating applications. Regular re-greasing to replenish the film is also critical.

For a maintenance manager or parts supplier, this knowledge is diagnostic. When a pillow block fails, you can look at the failure mode and trace it back to a specification shortfall. The table below acts as a troubleshooting and specification guide:

| Observed Failure | Likely Root Cause in Mining | Spec Solution for Replacement/New Design |

|---|---|---|

| Bearing filled with gritty paste | Seal failure, contamination ingress. | Upgrade to multi-labyrinth or PTFE seals. |

| Cracked housing | Insufficient shock resistance. | Use ductile iron (500-7) or cast steel housing. |

| Worn shaft under the bearing | Inner ring creep due to poor fit. | Use adapter sleeve mounting or ensure correct shaft tolerance (k6/m6). |

| Bearing noise on vibrating screen | False brinelling from micro-movement. | Select bearings with C4 clearance or "V" designation for vibration. |

At FYTZ, we engineer our heavy-duty pillow block range to combat these exact problems. We offer housings in ductile iron, seals designed for slurry, and can pre-load bearings for vibrating applications. This turns a list of common problems into a checklist of solved challenges for our distributors and their mining clients.

What is another name for a pillow block bearing?

In technical drawings, catalogs, and site conversations, you’ll hear different terms. Knowing these aliases is essential for clear communication, especially in international trade and when dealing with technical specifications from different regions.

Another common name for a pillow block bearing is a plummer block. The terms are often used interchangeably, though "pillow block" is more common in North America and general industry, while "plummer block" is frequently used in British-influenced regions and heavy industries like mining. They both refer to a bearing housing with two bolts for mounting to a horizontal surface.

Navigating the Terminology in Heavy Industry and Global Trade

Beyond the basic name, there is a whole family of related units. Understanding this family helps you specify and source the exact component you need.

1. The Core Family: Pillow Block = Plummer Block

This is the standard unit with a two-bolt base for mounting on a flat surface. When someone in a South African mine says "plummer block," they mean the same thing as "pillow block" in a Brazilian quarry.

2. The Flange Block Cousins

These are used when mounting on a vertical surface or where space is constrained.

- Flange Block: A housing with a circular flange and bolt holes for mounting.

- Take-Up Unit: A specialized block set in a sliding frame to adjust belt tension on conveyors. This is extremely common in mining conveyors.

3. The "SAF" and "SD" Series: The Heavy-Duty Standard

In mining and heavy industry, you often encounter codes like SAF 22230 or SD 22320. These are not just names; they are standardized dimensional plans.

- SAF Series: A standardized "self-aligning flanged" housing unit. The "22230" refers to the spherical roller bearing insert size. This system guarantees interchangeability between manufacturers.

- SD Series: The "self-aligning" housing with a "detachable" (split) housing. This is the classic heavy-duty split pillow block.

Why This Matters for Sourcing and Specification:

Using the correct terminology ensures you get the right part and can communicate effectively with global suppliers.

- If an OEM drawing calls for a "Plummer Block, SAF 22230," you know you need a specific, interchangeable unit with a 150mm bore spherical roller bearing.

- If you ask a supplier for a "pillow block for a 150mm shaft," you might get various options. If you ask for an "SD 22330 housing with a C4 clearance spherical roller bearing," you get exactly what the application needs.

For a global distributor like Rajesh’s company, mastering this terminology is business-critical. When a mining company in India requests "Plummer Blocks for their conveyor," Rajesh’s team knows to ask for the SAF or SD number or the shaft size and load details to match it to the correct FYTZ heavy-duty product. This precision prevents errors, builds trust, and positions them as experts, not just order-takers.

Conclusion

Mining and quarry pillow block bearings are engineered survival systems, not commodity components. Success depends on specifying for extreme load, contamination, and shock, understanding load ratings in context, proactively addressing common failure modes, and using precise terminology to ensure you get the heavy-duty solution your operation demands.

-

Understanding seal failure can help you choose the right pillow block to prevent contamination and extend equipment life. ↩ ↩ ↩ ↩

-

Explore solutions to prevent housing fractures, ensuring durability and reliability in harsh mining environments. ↩ ↩ ↩ ↩

-

Learn about the causes of bearing creep to improve your pillow block specifications and reduce wear. ↩ ↩

-

Discover effective lubrication strategies to maintain optimal performance and longevity of your pillow blocks. ↩ ↩

-

Understanding false brinelling can help you select the right bearings for vibrating applications, enhancing performance. ↩

-

Explore the benefits of multi-stage labyrinth seals for better protection against contamination in harsh environments. ↩