Your machine’s bearings are failing too soon. You replaced them with high-quality units, but the problem returns. The issue might not be the bearing itself, but an invisible force bending its internal components: shaft misalignment. It’s a silent killer that accounts for a huge portion of premature failures.

Misalignment forces bearing rollers to skid and scrub instead of roll, creating edge loading, excessive heat, and vibration. This drastically accelerates wear and fatigue, shortening bearing life by up to 90%. Prevention requires proper installation alignment, using self-aligning bearings, and regular checks to correct drift caused by operation and settling.

A perfectly manufactured bearing cannot compensate for a poorly aligned system. Misalignment doesn’t just reduce life; it actively destroys the bearing from day one. For maintenance teams and equipment designers, understanding and combating misalignment is non-negotiable for reliability. Let’s explore this critical issue.

Can misalignment cause bearing failure1?

Absolutely, and it’s one of the leading causes. A bearing is designed for pure rolling motion. Misalignment distorts this motion, turning smooth rotation into a grinding, destructive process. I’ve seen bearings destroyed in weeks by misalignment that would have lasted years in a straight system.

Yes, misalignment is a primary cause of bearing failure1. It creates uneven load distribution across the rollers, leading to localized stress2 (edge loading3), increased friction and heat, excessive vibration, and rapid wear of raceways, rollers, and cages. This process quickly leads to spalling4, overheating, and catastrophic seizure.

The Mechanics of Destruction: How Misalignment Kills a Bearing

To prevent it, you must understand how it works. The damage follows a predictable and devastating chain reaction.

1. The Initial Insult: Edge Loading

Imagine a perfectly aligned shaft. The load is distributed evenly across the full length of the roller. Now, tilt the shaft. The roller no longer sits square in the raceway. It contacts the raceway only at one edge. This is edge loading3. The entire load is now carried by a tiny area of the roller and raceway, creating immense localized stress2—far beyond the design limits.

2. The Secondary Effects: Skidding, Friction, and Heat

Because the roller is skewed, it cannot roll cleanly. It must skid and scrub along the raceway. This sliding friction generates significant heat. The heat has two effects:

- It degrades the lubricant, breaking down its protective film.

- It can soften the bearing steel (tempering), reducing its hardness and wear resistance.

3. The Vicious Cycle and Final Failure

- Increased heat > Lubricant fails > Metal-to-metal contact increases > More heat and wear > Vibration increases.

- The high stress from edge loading3 initiates micro-cracks below the surface (fatigue).

- These cracks grow and eventually cause spalling4—chunks of material flaking off the raceway or rollers.

- The bearing becomes noisy, hot, and finally seizes or disintegrates.

For anyone responsible for machinery, this is a critical failure mode to recognize. The table below links specific misalignment types to their destructive mechanisms:

| Type of Misalignment | What Happens Inside the Bearing | Primary Failure Mode |

|---|---|---|

| Angular Misalignment (Shafts at an angle) | Rollers are forced into a cone shape, causing severe edge loading3 at one end of each roller. | Rapid spalling4 on raceway and roller ends. |

| Parallel/Offset Misalignment (Shafts parallel but offset) | Creates a bending moment on the bearing, uneven load distribution around the bearing circumference. | Increased vibration, uneven wear around the raceway. |

| Combined Misalignment (Both angular and parallel) | The worst-case scenario, combining both destructive effects. | Extremely rapid progression to catastrophic failure. |

When a bearing supplied by a distributor like Rajesh’s company fails early, misalignment should be the first suspect after lubrication. Educating customers to check alignment before blaming the bearing saves relationships and identifies the true root cause.

How to prevent shaft misalignment1?

Prevention is always cheaper than repair and downtime. Preventing misalignment is a combination of good design, precise installation, and proactive maintenance. It’s a process, not a one-time event.

Prevent shaft misalignment1 by ensuring precise initial installation using laser or dial indicator alignment tools, designing rigid foundations and frames to resist deflection, using self-aligning bearing types where appropriate, implementing proper coupling selection and installation, and conducting regular alignment checks as part of preventive maintenance to correct thermal and operational drift.

A Multi-Layer Defense Strategy Against Misalignment

Think of alignment as a system with several lines of defense, from design to daily operation.

1. The Foundation: Design and Mounting

- Rigid Supports: The machine frame and base must be strong and stable. Weak frames flex under load, creating dynamic misalignment.

- Proper Machining: Bearing seat surfaces on the frame must be machined flat and square. Shim packs should be used for precise height adjustment, not random washers.

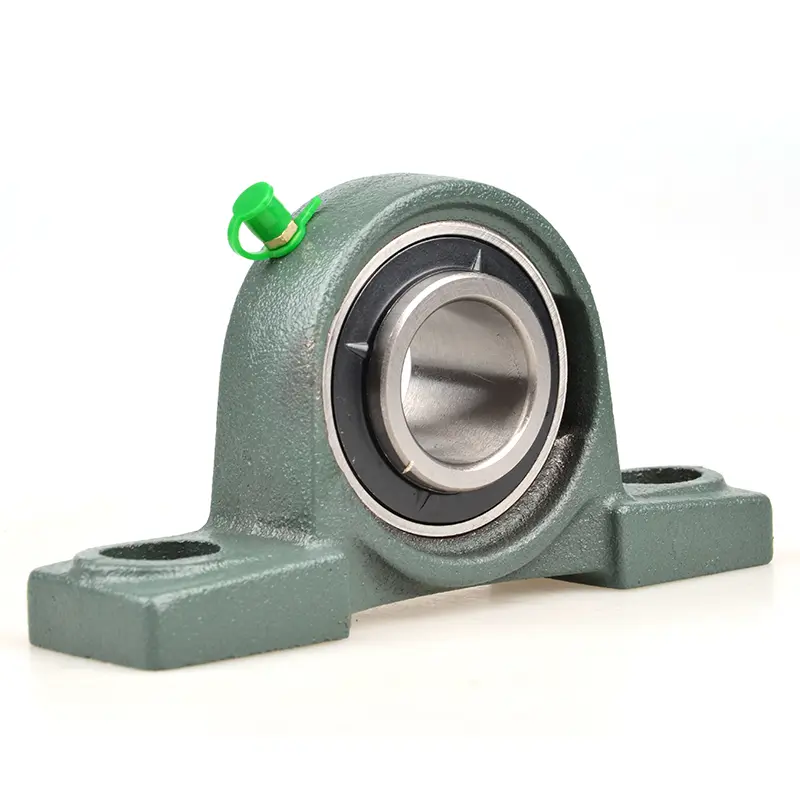

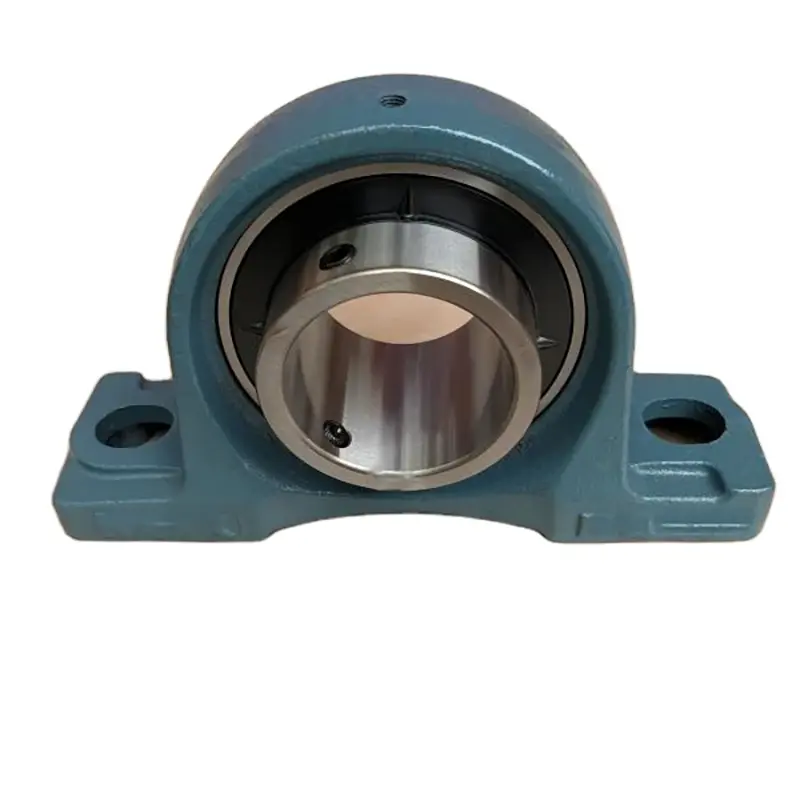

- Correct Bearing Selection: In applications where some misalignment is inevitable (like on long conveyors or due to thermal expansion), specify self-aligning bearings2 (spherical roller bearings in pillow blocks) from the start. This is a proactive design choice.

2. The Critical Phase: Precision Installation

This is where most errors occur. "Eyeballing" is not acceptable.

- Use Proper Tools: Laser alignment systems are the modern standard for accuracy and speed. Dial indicators are a reliable, lower-cost alternative. Both are far superior to a straightedge or feeler gauge.

- Follow a Procedure: Align in steps: rough alignment, soft foot check (ensuring all machine feet are in solid contact), then fine alignment. Always align to the driven machine (e.g., the pump), not the motor.

- Consider Thermal Growth: For equipment that runs hot (like turbines, dryers), you may need to perform "hot alignment" or set a "cold offset" based on the manufacturer’s data, so it aligns perfectly at operating temperature.

3. The Ongoing Effort: Maintenance and Monitoring

Alignment is not permanent. Machines settle, frames shift, components wear.

- Schedule Regular Checks: Include alignment verification in your preventive maintenance schedule, especially after any work on the machine or its foundation.

- Monitor Condition: Increasing vibration is often the first sign of developing misalignment. Trend vibration data3 to catch problems early.

For a bearing supplier or distributor, your role extends beyond the part. You can provide value by promoting alignment awareness. When Rajesh’s company sells a pair of pillow blocks to a factory, they can include a simple leaflet or link to a video on basic alignment principles. This helps their customers succeed, ensuring the FYTZ bearings they install achieve their full design life. This builds loyalty and reduces unjustified warranty claims.

What consequences can occur with a misaligned shaft?

Misalignment doesn’t just hurt the bearing. It sends shockwaves through the entire drive train, wasting energy, damaging other components, and creating safety hazards. The bearing failure is often just the most visible symptom of a systemic problem.

A misaligned shaft causes premature bearing failure1, excessive vibration2 leading to seal and housing damage, increased energy consumption3 due to friction, coupling wear or failure4, shaft fatigue and potential fracture5, excessive noise, and overall reduced reliability and productivity6 of the machine.

The Ripple Effect of a Misaligned System

The costs of misalignment compound quickly, affecting operational expenses and capital assets.

1. Direct Bearing Damage (The Immediate Cost)

As detailed, this is the primary and most frequent consequence. It leads to:

- Frequent bearing replacements.

- Cost of downtime for repairs.

- Labor costs for maintenance.

2. Vibration: The Destroyer of Everything

Misalignment is a direct source of forced vibration.

- Seal Damage: Excessive vibration destroys lip seals, allowing lubricant leakage and contaminant ingress.

- Housing and Bolt Fatigue: Vibration can loosen mounting bolts, crack bearing housings, and fatigue welds on frames.

- Foundation Damage: Severe vibration can transfer to the foundation, causing long-term structural issues.

3. Energy Waste: The Silent Profit Drain

The increased friction from skidding rollers and the constant flexing of the shaft and coupling require more motor torque. This translates directly into higher electricity consumption. Studies show misalignment can increase energy use by 5-15% in a typical motor-driven system.

4. Coupling Failure

The coupling is designed to transmit torque and accommodate small amounts of misalignment. Excessive misalignment overloads the coupling’s flexing elements (discs, grids, elastomers), leading to premature wear, tear, and failure.

5. Shaft Stress and Potential Failure

A misaligned bearing imposes bending stresses on the shaft. Over time, this can lead to shaft fatigue, resulting in cracks and ultimately catastrophic shaft failure, which is a much more expensive repair than a bearing change.

For a plant manager or business owner, this list translates into real financial impact. The table below quantifies the broader consequences:

| Consequence | Direct Impact | Indirect Business Impact |

|---|---|---|

| Bearing Failure | Part + labor cost for replacement. | Production downtime, missed deadlines. |

| Increased Vibration | Damage to seals, housings, other components. | More extensive repairs, higher spare part inventory. |

| Higher Energy Use | Increased electricity bill. | Reduced profitability, higher carbon footprint. |

| Coupling/Shaft Failure | Cost of more expensive components and repair. | Major unplanned downtime, safety risks. |

Understanding this full picture makes the investment in proper alignment tools and procedures clearly worthwhile. It’s not a maintenance luxury; it’s a core reliability and profitability strategy.

What bearings are best for misalignment?

You cannot always eliminate misalignment. Frames warp, shafts bend under load, and temperatures change. Therefore, selecting a bearing that can tolerate some misalignment is a smart engineering decision. This is where the pillow block’s internal bearing choice becomes critical.

The best bearings for accommodating misalignment are self-aligning bearings1. These include:

- Spherical Roller Bearings: The best choice for heavy-duty applications. They can accommodate 1-3 degrees of angular misalignment2.

- Self-Aligning Ball Bearings: For lighter loads and higher speeds.

- CARB Toroidal Roller Bearings: Specialized for very high misalignment and axial movement.

For pillow blocks in industrial settings, spherical roller bearing inserts are the standard and most effective solution for misalignment.

Why Spherical Roller Bearings are the Industrial Champion for Misalignment

Among self-aligning options, spherical roller bearings3 offer the best combination of misalignment tolerance, load capacity, and robustness for pillow block applications.

1. The Design Principle: Internal Freedom

A spherical roller bearing has two rows of barrel-shaped rollers. They run on a spherical raceway in the outer ring. This allows the entire inner ring and roller assembly to pivot or self-align within the outer ring. The bearing corrects its own internal geometry to match the shaft angle, ensuring the rollers maintain proper contact.

2. Key Advantages in Misalignment Service

- High Load Capacity: They maintain excellent radial and axial load capacity even when misaligned, unlike other types whose capacity drops sharply.

- Robustness: The design is tough, handling the shock and vibration that often accompany misaligned conditions.

- Common and Cost-Effective: They are widely available and offer the best value for performance in demanding industrial environments.

3. Important Limitations to Remember

- They Are Not a Cure-All: Spherical rollers tolerate misalignment; they do not thrive on it. The allowable angle (e.g., 0.5° to 2°) is a safety buffer, not an operational target. You should still aim for the best possible alignment.

- Axial Misalignment vs. Parallel Misalignment: They are excellent for angular misalignment. They do not compensate for large parallel (offset) misalignment; that must be corrected mechanically.

Selecting the Right Pillow Block for Misalignment-Prone Applications:

For distributors and engineers, the specification is clear. The table below guides the choice:

| Application Context | Likely Misalignment Source | Recommended Pillow Block Specification |

|---|---|---|

| Long Conveyor | Frame settling, thermal expansion. | Standard Duty: Split housing pillow block with spherical roller bearing (222 series). |

| Heavy Gearbox/Motor Drive | Foundation shift, load deflection. | Heavy Duty: SAF/ SD series housing with spherical roller bearing (223, 230 series). |

| High-Speed Fan | Thermal growth, housing distortion. | For higher speeds: Spherical roller bearing with machined brass cage for stability. |

| Extreme Misalignment (e.g., agricultural equipment) | Severe frame flexing. | CARB bearing pillow block or spherical roller with wide inner ring. |

At FYTZ Bearing, we specialize in spherical roller bearings3 and the pillow blocks that house them. We know that for our global customers in mining, cement, and power generation, misalignment is a fact of life. By providing high-quality, reliable spherical roller bearing units, we give our distributors like Rajesh the right tool to solve a fundamental industrial challenge, ensuring their customers’ machinery keeps running despite imperfect conditions.

Conclusion

Misalignment is a primary destroyer of pillow block bearing life, but it is a manageable threat. By understanding its destructive effects, implementing precise alignment practices, and strategically selecting self-aligning spherical roller bearings, you can dramatically extend bearing service life and improve overall machine reliability.

-

Explore the advantages of self-aligning bearings for better performance in misalignment situations. ↩ ↩ ↩ ↩ ↩ ↩

-

Gain insights into angular misalignment and its impact on bearing performance. ↩ ↩ ↩ ↩ ↩

-

Learn why spherical roller bearings are the top choice for handling heavy loads and misalignment. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Identifying the causes of coupling wear can help in selecting the right components and improving system reliability. ↩ ↩ ↩ ↩

-

Recognizing signs of shaft fatigue can prevent catastrophic failures and ensure operational safety. ↩

-

Understanding the link between reliability and productivity can drive improvements in manufacturing processes. ↩