You are about to order a container of spherical roller bearings from China. The price is right. But you have heard stories: inconsistent quality, failed shipments, angry customers. How do you protect your investment and your reputation? A proactive, documented QC checklist is your essential tool.

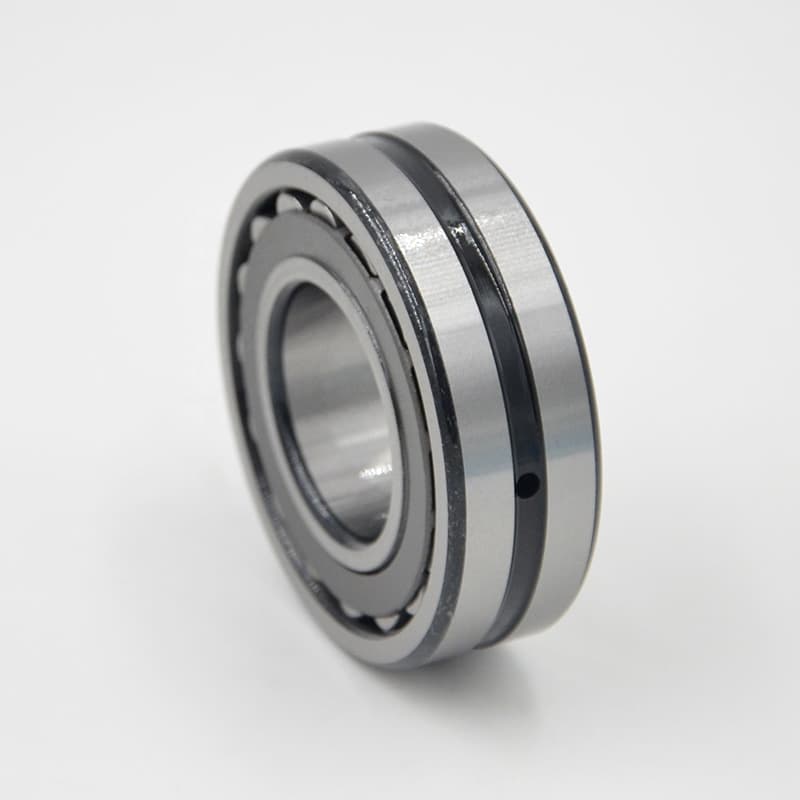

A comprehensive QC checklist for spherical roller bearings from China must cover documentary review (ISO standards, material certs), dimensional checks (bore, OD, width), visual and tactile inspection (surface finish, seals, smooth rotation), performance testing (vibration per ISO 15242), and packaging/labeling verification. Partnering with a factory that has integrated quality control, like FYTZ, is crucial.

China produces both world-class and sub-standard bearings. The difference is often in the buyer’s diligence. A checklist turns hope into a systematic verification process. Whether you’re a first-time importer or a seasoned distributor like Rajesh, this guide will help you secure reliable quality. Let’s build that checklist step by step.

What is the ISO standard for spherical roller bearings?

Your checklist starts with a standard. ISO standards are the universal language of quality. They tell the supplier what you expect, and they give you the objective criteria to judge what you receive. Without referencing ISO, you are buying on faith.

For spherical roller bearings, key ISO standards include ISO 151 (dimensional series), ISO 76/2812 (load ratings), ISO 4923 (tolerances), and ISO 152424https://www.iso.org/obp/ui/en/#!iso:std:69977:en)[^1]242 (vibration). Requiring compliance with these standards in your purchase order and verifying it during QC ensures you receive a product with predictable performance and interchangeability.

Turning ISO Standards into Actionable Checklist Items

Simply writing "must meet ISO" is not enough. You must break each standard down into specific checks you or a third-party inspector can perform.

1. Documentary Check: The First Line of Defense

Before you even inspect the physical bearing, check the documents.

- Checklist Item 1.1: Verify the supplier provides a Certificate of Compliance stating the bearings conform to ISO 151, 76, 281, 492.

- Checklist Item 1.2: For critical applications, request Material Test Certificates (MTC) for the steel, proving grade (e.g., GCr15/52100) and cleanliness.

- Checklist Item 1.3: Request Vibration Test Reports per ISO 152424https://www.iso.org/obp/ui/en/#!iso:std:69977:en)[^1]242 for the batch or a sample. This data is a powerful indicator of internal manufacturing quality.

2. Dimensional Check: The Fit and Function Verification

- Checklist Item 2.1: Using calibrated micrometers and bore gauges, measure the Bore (d), Outside Diameter (D), and Width (B or C) of a statistical sample (e.g., AQL Level II). Compare to the tolerance limits specified in ISO 4923 for the declared tolerance class (usually P0/Normal).

- Checklist Item 2.2: Check chamfer dimensions and ring thickness. Significant deviations can affect fit in the housing or against shoulders.

3. Performance Pre-Check: Vibration

- Checklist Item 3.1: If possible, perform a basic vibration check on a sample using a portable tester. While not a full ISO 152424https://www.iso.org/obp/ui/en/#!iso:std:69977:en)[^1]242 lab test, it can identify gross outliers. Compare results to any supplied test reports.

By embedding ISO standards into your checklist, you shift the conversation. When you send your PO to a supplier like FYTZ, stating these requirements, it immediately filters out workshops that cannot comply. For Rajesh’s company, having this checklist ready makes factory audits and pre-shipment inspections efficient and objective.

Does SKF manufacture bearings in China?

This question reveals a common concern: "If I buy from China, am I getting a cheap imitation?" The reality is more nuanced. Many global brands, including SKF, have manufacturing plants in China. But they control the process tightly. Your checklist must help you identify suppliers who operate with similar discipline, even if they are independent Chinese brands.

Yes, SKF manufactures bearings in China through its own factories and joint ventures. This demonstrates that China has the capability to produce world-class bearings. However, the market also has many smaller factories with varying quality levels. Your QC checklist must help you distinguish between a professionally run factory and a low-cost assembler.

Learning from Global Brands: What to Look for in a Chinese Supplier

You may not be buying SKF, but you should look for suppliers who emulate the systems that make SKF reliable. Your checklist should include a supplier qualification1 section before you even place the order.

1. Factory Audit Checklist (Pre-Order)

- Checklist Item A1: Does the factory have integrated production lines2 (forging, turning, heat treatment, grinding, assembly) or are they just an assembler buying components from the open market? Integrated control is better.

- Checklist Item A2: What in-process quality controls3 are in place? Look for statistical process control (SPC) charts on the shop floor, first-article inspection records, and final inspection stations.

- Checklist Item A3: Is there a dedicated metrology lab4 with calibrated equipment (CMMs, profilometers, hardness testers, vibration testers)? This is a strong sign of commitment to quality.

- Checklist Item A4: Ask for a tour of the heat treatment department. Proper, controlled heat treatment is the heart of bearing life. Chaotic or outsourced heat treatment is a major red flag.

2. How This Relates to Your Physical QC

If you have qualified a factory like FYTZ, which has these systems, your incoming QC checklist on the shipment can be more of a verification sample check. If you bought from an unknown trader, your checklist must be far more rigorous and your sampling rate much higher, as you are effectively doing the final inspection they may have skipped.

The Importer’s Reality:

Most importers like Rajesh cannot audit every small supplier. The practical approach is to partner with a few established, integrated manufacturers with proven export records. Your initial due diligence (the factory audit checklist) is more important than trying to catch every defect at the port. A good supplier wants to pass your QC; a bad supplier will always find ways to hide problems.

How to check bearing quality?

This is the core of your checklist—the hands-on inspection you or your agent performs on the shipment before payment. It moves from documents to physical reality. A systematic approach prevents you from being overwhelmed.

To check spherical roller bearing quality, perform a multi-stage inspection: 1) Dimensional verification1 of bore, OD, width, and chamfers; 2) Visual & tactile inspection2 for surface defects, proper stamping, smooth rotation, and seal integrity; 3) Functional testing3 for vibration and noise; and 4) Packaging and marking check4.

A Detailed, Step-by-Step Physical QC Checklist

Here is a breakdown of practical checks you can implement, even in a warehouse setting.

1. Dimensional and Geometric Checks

- Checklist Item P1: Bore Diameter. Use a bore gauge or an internal micrometer. Measure at several points and angles to check for roundness and taper. Record values against the ISO tolerance.

- Checklist Item P2: Outside Diameter and Width. Use a micrometer. Check for conformity to dimensions.

- Checklist Item P3: Radial Clearance5 (Optional but valuable). For a more thorough check, measure the radial internal clearance using a dial indicator. It should correspond to the specified clearance group (C3, C4, etc.).

2. Visual and Tactile Inspection

- Checklist Item P4: Surface Finish6. Examine raceways and rollers under good light. Look for grinding burns (bluish tint), scratches, nicks, or rust. Surfaces should be smooth and uniformly finished.

- Checklist Item P5: Markings. Check that the bearing is clearly stamped with the brand, bearing number, origin (e.g., China), and clearance group (if not standard). Faint or missing stamps are a red flag.

- Checklist Item P6: Manual Rotation. Hold the bearing. Rotate it slowly by hand. It should rotate smoothly and quietly without any binding, gritty feeling, or intermittent tight spots. Listen for any grinding or scraping sounds.

- Checklist Item P7: Seal/Shield Inspection. For sealed bearings, ensure the seals are properly fitted, not crooked or damaged. Check for grease leakage.

3. Packaging and Documentation (Final Gate)

- Checklist Item P8: Packaging. Bearings should be individually wrapped in anti-rust paper or plastic, properly boxed, and the boxes should be sturdy enough for export. Poor packaging leads to corrosion and damage in transit.

- Checklist Item P9: Shipping Mark vs. Purchase Order. Verify that the bearing number, quantity, and PO number on the shipping marks match your order exactly.

For an importer, empowering your warehouse team with this checklist is key. They don’t need to be master engineers; they need to follow clear steps. The table below can be part of your checklist form:

| Check | Tool Needed | Acceptance Criteria | Accept | Reject | Notes |

|---|---|---|---|---|---|

| Bore Diameter | Bore Gauge | Within ISO 492 tolerance for declared class. | ☐ | ☐ | |

| Hand Rotation | None | Smooth, free, no noise or binding. | ☐ | ☐ | |

| Surface Finish6 | Magnifying Glass | No burns, deep scratches, or rust. | ☐ | ☐ | |

| Markings | None | Clear, stamped with correct number & origin. | ☐ | ☐ | |

| Packaging | Visual | Individual anti-rust wrap, sturdy box. | ☐ | ☐ |

Who is the largest bearing manufacturer in China?

Knowing the landscape helps you set expectations. The largest player sets a certain benchmark for scale and capability. However, for many importers, the "largest" may not be the most suitable partner. Your checklist should help you find the right partner, which might be a large, medium, or specialized manufacturer.

The largest bearing manufacturer in China is the C&U Group1. It is a massive, publicly listed company with a full range of bearings and a significant global market share. Other major players include ZWZ2, HRB3, and LYC4. These are huge, state-influenced enterprises. However, many export-focused, privately-owned factories like FYTZ Bearing offer competitive quality with greater flexibility and direct customer focus for B2B wholesalers.

Choosing Between Giants and Focused Exporters: Implications for Your QC

The size and type of manufacturer you choose will influence where you need to focus your quality control5 efforts.

1. Dealing with the Industry Giants (C&U, ZWZ2, etc.)

- Strengths: Immense scale, complete R&D, ability to supply any bearing type. Quality is generally good and consistent for their standard lines.

- Challenges for Importers: They often prioritize large OEM contracts. Minimum order quantities (MOQs) can be high for direct orders. Communication can be slower through layers of management. As an importer, you might be buying through a trading company, adding a layer that obscures the factory’s actual QC data.

- QC Focus: Your checklist must be strictly enforced because you may have less direct influence over the manufacturing process. Reliance on third-party pre-shipment inspection (PSI) is common.

2. Partnering with Focused Export Factories (like FYTZ)

- Strengths: Often more flexible on MOQs and customization. Communication is typically more direct and responsive. They are hungry for export business and may be more willing to provide detailed QC documentation and accommodate your specific checklist requirements.

- Challenges: You must conduct thorough due diligence to verify their actual capabilities, as the range of quality among such factories is wide.

- QC Focus: Your initial factory audit checklist is critical. If they pass, you can often establish a more collaborative QC relationship. They may allow you to specify inspection protocols and provide in-process data.

The Importer’s Strategic Choice:

For a distributor like Rajesh’s company, ordering 3-5 containers a year, a giant like C&U might be inaccessible directly. A focused exporter like FYTZ is a perfect match. The QC process can be more integrated. Rajesh can specify that his shipments must pass the FYTZ internal vibration test (with reports provided) and can send his own inspector for pre-shipment checks more easily. This partnership model, backed by a rigorous checklist, often yields better value, control, and long-term reliability than buying generic "Chinese bearings" from a faceless trader.

Conclusion

A robust QC checklist is your essential toolkit for sourcing spherical roller bearings from China. It combines documentary verification, dimensional checks, physical inspection, and an understanding of the supplier landscape to transform sourcing from a gamble into a managed, low-risk business process.

-

Explore the C&U Group’s extensive offerings and market influence to understand their role in the bearing industry. ↩ ↩ ↩ ↩ ↩

-

Learn about ZWZ’s capabilities and how they stack up against other major players in the industry. ↩ ↩ ↩ ↩ ↩

-

Investigate HRB’s standing and product quality to make informed sourcing decisions. ↩ ↩ ↩ ↩ ↩

-

Find out about LYC’s specialization and how it can meet your specific bearing needs. ↩ ↩ ↩ ↩ ↩ ↩

-

Enhance your understanding of quality control measures to ensure product reliability and performance. ↩ ↩

-

Surface finish affects the performance and longevity of bearings, making it a critical quality factor. ↩ ↩