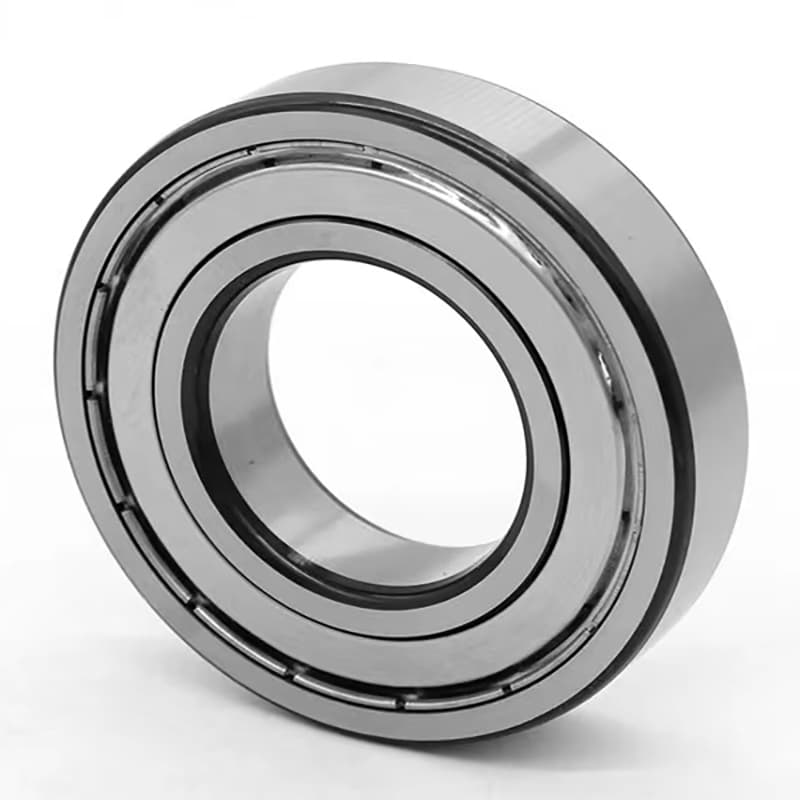

You installed new bearings. They fit the shaft and housing perfectly. But a strange noise starts within weeks—a clunking or rumbling. The bearing isn’t broken, but its life is draining fast. The hidden culprit is often the internal clearance, a dimension you never see but defines everything.

Incorrect radial internal clearance (too loose or too tight) in deep groove ball bearings causes premature failure. Too much clearance leads to vibration, impact loads, and noise. Too little clearance (preload) generates excessive heat and friction. Both conditions drastically accelerate wear and fatigue, cutting bearing life far short of its design potential.

Clearance is not an afterthought. It is a fundamental design parameter as critical as the bore size. Ignoring it turns a precision component into a problem. In real projects—from pumps in Egypt to motors in Vietnam—getting clearance wrong is a fast track to downtime. Let’s uncover why this invisible space matters so much.

Think of a loose bearing like a loose wheel on a car. It wobbles. In a bearing, this wobble isn’t just side-to-side play; it’s a destructive force that attacks the bearing from the inside. I’ve seen this cause failures in fans and conveyors that should have run for years.

If the main bearing clearance1 is too loose, the rolling elements (balls) can skid and impact the raceways instead of rolling smoothly. This causes excessive vibration2, increased noise (a rumbling or knocking sound), premature wear, and can lead to cage damage3 due to uncontrolled roller movement. The bearing loses precision and fails early.

A bearing needs a tiny amount of internal space to allow for thermal expansion4 and lubricant film. But when this space becomes too large, the stable rolling motion breaks down. The problems cascade.

1. Loss of Rolling Geometry and Skidding

Under ideal conditions, balls roll with minimal sliding. With too much clearance, the load zone becomes very small. Balls in the unloaded zone are not properly constrained. When they enter the load zone, they can skid or skew instead of rolling. Skidding scrapes the metal surfaces, generating heat and wear particles that contaminate the lubricant.

2. Impact Loading and Vibration

This is the most direct damage. As the shaft rotates, the loose balls have room to move radially. When the load direction changes (which it does constantly in a rotating system), the balls are slammed against the raceway. This is impact loading5. Instead of a smooth, distributed force, the raceway suffers repeated hammer-like blows. This causes:

3. Cage Damage and Potential for Jamming

The cage’s job is to keep the balls separated and guided. With excessive clearance, balls move unpredictably. They can hit each other or hammer against the cage pockets. This leads to cage wear, cracking, or even complete fracture. A broken cage can cause balls to cluster and jam, leading to instantaneous seizure.

4. The "Real Project" Scenario: Misdiagnosis

In a factory, the symptoms of loose clearance (noise, vibration) are often mistaken for imbalance or misalignment. Maintenance teams might spend time rebalancing a fan or realigning a motor, but the problem persists because the root cause is inside the bearing. Replacing the bearing with another of the same incorrect clearance group perpetuates the cycle.

For a bearing supplier or maintenance provider, understanding this chain is key to diagnosis. The table below links observable symptoms back to the root cause of excessive clearance:

| Symptom on Site | Underlying Mechanical Action | Long-Term Consequence |

|---|---|---|

| Low-frequency rumbling noise | Balls impacting raceways due to radial play. | Raceway brinelling and spalling. |

| Shaft feels "loose" or has measurable radial play | Excessive internal clearance allows shaft movement. | Accelerated wear on seals and housing fits. |

| Increased vibration at 1x or 2x running speed | Unbalanced load distribution and impact forces. | Fatigue failure of bearing and possibly the machine frame. |

| Cage fracture found during inspection | Uncontrolled ball movement hammering the cage. | Catastrophic bearing seizure and possible shaft damage. |

At FYTZ, when we produce deep groove ball bearings, we strictly control internal clearance groups6 (C2, CN, C3, etc.). When a distributor like Rajesh’s company supplies bearings for a project, they must know the application’s thermal conditions to recommend the right clearance. A motor in a hot climate might need a C3 bearing to account for shaft expansion, while a precision instrument might need a CN. Getting this recommendation right from the start prevents the costly domino effect of "too loose."

Every bearing type has trade-offs. The deep groove ball bearing’s versatility comes with specific limitations. If your application pushes against these limits, you will see rapid failure. Incorrect clearance makes these inherent disadvantages much worse.

The main disadvantages of deep groove ball bearings are their limited axial load capacity compared to dedicated thrust bearings, their sensitivity to misalignment, their lower radial load capacity compared to roller bearings of the same size, and their need for precise internal clearance control. They are not ideal for very heavy loads or severe shock loads.

These disadvantages aren’t flaws; they are design boundaries. A successful application stays within these boundaries. Incorrect clearance effectively moves the boundary, making the bearing fail even under normal loads.

1. Limited Axial Load Capacity1

2. Sensitivity to Misalignment3

3. Lower Radial Load Capacity vs. Roller Bearings4

4. Necessity for Precise Clearance Control5

For an equipment designer or a bearing importer, respecting these limits is crucial. When selecting a bearing for a pump that will have some axial thrust, you might need to pair it with a thrust washer or choose a different bearing type altogether, rather than hoping a deep groove ball bearing will cope. At FYTZ, we can advise on this. We can also manufacture bearings with non-standard clearances (wider or narrower) to help a design stay within the safe zone of this versatile but specific component.

In the field, "too much clearance1" has a signature. It’s not a silent failure. It announces itself through noise, vibration, and a feeling of looseness. These are not just symptoms; they are the visible signs of active destruction inside the bearing.

A bearing with too much clearance1 causes uncontrolled movement of the rolling elements, leading to impact loads, skidding, excessive vibration, audible knocking or rumbling noises, rapid wear of raceways and balls, increased heat from friction, and accelerated failure of the cage and seals.

Let’s trace the cause-and-effect pathway from that extra thousandth of an inch of space to a seized bearing on the shop floor.

Stage 1: The Initiation of Impact

The shaft rotates. Due to clearance, it can move radially within the bearing. Under load (like the weight of a pulley), the shaft settles to one side. As it rotates, the load vector rotates with it. The balls are repeatedly picked up and dropped onto the raceway. This is low-cycle impact fatigue2. Each impact creates a tiny dent or accelerates microscopic cracks.

Stage 2: The Contamination Cycle

The impact and skidding generate wear debris—microscopic particles of steel. These particles are harder than the parent material due to work hardening. They mix with the lubricant, creating an abrasive paste3. This paste now grinds away at all bearing surfaces, accelerating wear and creating more debris—a vicious cycle.

Stage 3: The Thermal and Stability Breakdown

Stage 4: Catastrophic Failure Modes

The end can come in several ways:

For a maintenance technician, the diagnostic clues are clear. If you can grasp the inner ring of an installed bearing and feel a distinct "clunk" by moving it radially, the clearance is almost certainly excessive. This simple check can prevent a major failure. For a bearing distributor, educating customers on this simple check is a valuable service. When Rajesh’s team in Mumbai trains a local motor repair shop to check for play, they help that shop diagnose problems correctly, leading to more accurate replacement part orders and happier end-customers.

Clearance is the bearing’s breathing room. It is the space that allows it to live. Get it wrong, and you suffocate it with heat or break its bones with impact. It is the single most critical internal dimension after the basic size.

Bearing clearance is critically important because it accommodates thermal expansion2 of the shaft and inner ring, ensures proper lubricant film formation, allows for minor misalignments, and directly influences bearing stiffness, vibration, noise, operating temperature, and ultimate service life. It is the adjustment parameter that matches the bearing to its specific operating environment.

That tiny gap isn’t empty; it’s a functional zone that performs several essential jobs simultaneously. Eliminating it or making it too large disrupts all these functions.

1. Thermal Expansion Accommodation

This is the primary reason for clearance. When a machine runs, the shaft gets hotter than the housing. The inner ring expands onto the shaft. If there is zero clearance to start with, this expansion creates preload3 (negative clearance), squeezing the balls and generating destructive heat. Correct initial clearance allows for this expansion without creating preload3.

2. Enabling Elastohydrodynamic (EHD) Lubrication

For lubricant to form a protective film between the ball and raceway, there must be space for it to flow. The correct clearance creates the right pressure profile in the contact zone to "solidify" the oil film. Incorrect clearance alters this pressure, leading to metal-to-metal contact.

3. Managing Load Zone and Stress Distribution

With correct clearance, a sufficient number of balls share the load in a well-defined zone. This distributes stress evenly. With incorrect clearance, the load zone4 shrinks (if loose) or encompasses too many balls under stress (if tight), leading to stress concentration.

4. Influencing System Dynamics

For project engineers and bearing specifiers, selecting clearance is a deliberate act. It requires answering: How hot will the inner ring get? What is the precision requirement? What are the expected loads? The industry provides standardized clearance groups5 (C2, CN, C3, C4) for this purpose. The table below is a fundamental guide:

| Clearance Group | Typical Application Context | Purpose & Benefit |

|---|---|---|

| C2 | Precision spindles, instruments, low-noise applications. | Minimal play for high accuracy and stiffness. Requires stable, cool temperatures. |

| CN (Normal) | General applications, stable temperatures, good alignment. | The default. Balances most needs for common industrial use. |

| C3 | Electric motors, applications where inner ring heats significantly, fits with slight interference. | Prevents preload3 from thermal expansion2. Common in motors and pumps. |

| C4 | High-temperature applications, very tight fits, vibrating screens. | Extra allowance for large differential expansion or where loose fit is unacceptable. |

At FYTZ Bearing, we manufacture to all these clearance groups5. Our role, through distributors like Rajesh’s company, is to educate the market. When an OEM in Vietnam designs a new generator, we can advise that the bearing on the hot end likely needs a C3 clearance, while the cooler fan end might use CN. This application-specific guidance, rooted in the fundamental importance of clearance, is what ensures our bearings deliver their full, promised life in real-world projects.

Incorrect internal clearance is a silent killer of deep groove ball bearings. It transforms a precision component into a source of impact, heat, and vibration, leading to premature failure that is often mistaken for other problems. Specifying and maintaining the correct clearance is the most effective step toward achieving design life.

Understanding bearing clearance is crucial for ensuring optimal performance and longevity of machinery. ↩ ↩ ↩ ↩ ↩ ↩ ↩

Explore how thermal expansion impacts bearing function and why it’s vital for machinery efficiency. ↩ ↩ ↩ ↩ ↩ ↩ ↩

Learn about preload and its critical role in bearing performance and longevity. ↩ ↩ ↩ ↩ ↩ ↩

Discover the significance of load zones in bearings and their impact on stress management. ↩ ↩ ↩

Get insights into clearance groups and how they influence bearing selection for various applications. ↩ ↩ ↩ ↩

Learn about internal clearance groups to select the right bearings for your applications. ↩