Your dryer or kiln runs at over 150°C. A standard bearing inside fails every few months. The heat destroys the lubricant, weakens the steel, and warps the seals. I see this costly cycle often in industries from ceramics to food processing.

High-temperature pillow block bearings use heat-stable materials like special steel cages, high-temp greases, and sometimes solid lubricants. They are designed for sustained operation from 150°C up to 350°C, preventing the rapid failures seen with standard bearings in ovens, kilns, and dryers.

Standard bearings are not built for this fight. They fail fast. This leads to unplanned stops, lost production, and high replacement costs. Choosing the right high-temperature bearing is a strategic decision for reliability. Let’s explore what makes these bearings survive where others fail.

What bearings are suitable for high temperature?

You need a bearing that won’t melt, warp, or turn to dust inside your hot machine. The solution is not one magic bearing. It is a combination of specific materials and designs chosen to fight heat at every level.

Bearings suitable for high temperatures feature heat-treated or stainless steel rings, special cages (brass, steel, or phenolic), high-temperature synthetic greases1 or solid lubricants, and often increased internal clearance (C4, C5). Common types include deep groove ball bearings, cylindrical roller bearings, and spherical roller bearings in high-temperature configurations.

Building a Bearing for the Heat Battle

Heat attacks a bearing systematically. A suitable high-temperature bearing must defend against each attack vector. It is a complete system, not just a standard bearing with different grease.

1. The Defense of the Rolling Elements and Rings

The core bearing steel must resist softening.

- Standard Chrome Steel (GCr15/52100): This steel begins to temper (lose hardness) above 120-150°C. Its structure changes, making it soft and prone to wear. It is not suitable for sustained high temperatures.

- High-Temperature Stabilized Steel2: This is standard bearing steel that undergoes a special stabilization heat treatment. This process allows it to retain its hardness at temperatures up to 250°C or even 300°C for short periods. This is the most common solution for industrial high-temp applications.

- Stainless Steel (440C)3: Used for corrosion resistance, but its high-temperature performance (up to ~250°C) is also good. It is more expensive.

2. The Defense of the Cage (Retainer)

The cage is often the weak link. Plastic cages melt.

- Brass (Copper Alloy) Cages4: Excellent for high temperatures, good durability, but heavier.

- Steel Stamped or Machined Cages: Very robust and heat resistant.

- Phenolic (Polyamide) Resin Cages: Some high-grade phenolic cages5 can withstand temperatures up to 150-180°C, but you must check the specific material grade.

3. The Defense of the Lubrication System

This is the most critical system. Oil and grease evaporate or oxidize.

- High-Temperature Synthetic Greases: These use synthetic base oils (like PAO, ester) and thickeners (like polyurea, lithium complex) designed for 150°C to 200°C continuous operation. They have high dropping points and resist oxidation.

- Solid Lubricants6: For extreme temperatures (above 250°C), grease is impossible. Bearings may use graphite, molybdenum disulfide (MoS2), or PTFE coatings on raceways. These provide dry lubrication but have a finite life.

- Oil Lubrication with Cooling: For very high-speed, high-temperature applications, a circulating oil system with an external cooler is used.

For an importer like Rajesh, understanding this breakdown is key. When a customer in Egypt’s cement industry asks for a "high-temp bearing," Rajesh’s team needs to ask: "What is the actual temperature? Is it constant or cyclic?" The answer determines the specification. The table below guides this selection:

| Application Temperature Range | Suitable Bearing Specification | Key Components & Notes |

|---|---|---|

| 120°C – 150°C | Standard bearing with High-Temp Grease upgrade. | Often sufficient if temperature is at the upper limit of standard. Use polyurea grease. |

| 150°C – 200°C | Stabilized Steel rings, Steel/Brass Cage, C4/C5 clearance7, High-Temp Synthetic Grease. | The standard industrial high-temp solution for dryers and ovens. |

| 200°C – 300°C | Stabilized Steel, Solid Lubricant coating or special graphite cages. Grease life will be very short. | For kilns, high-temp conveyors. Requires shorter relubrication intervals or dry lube design. |

| >300°C | Special Alloys, Cooling Systems8, Airflow designs. Often custom solutions. | Beyond standard industrial bearing scope; requires engineered solutions. |

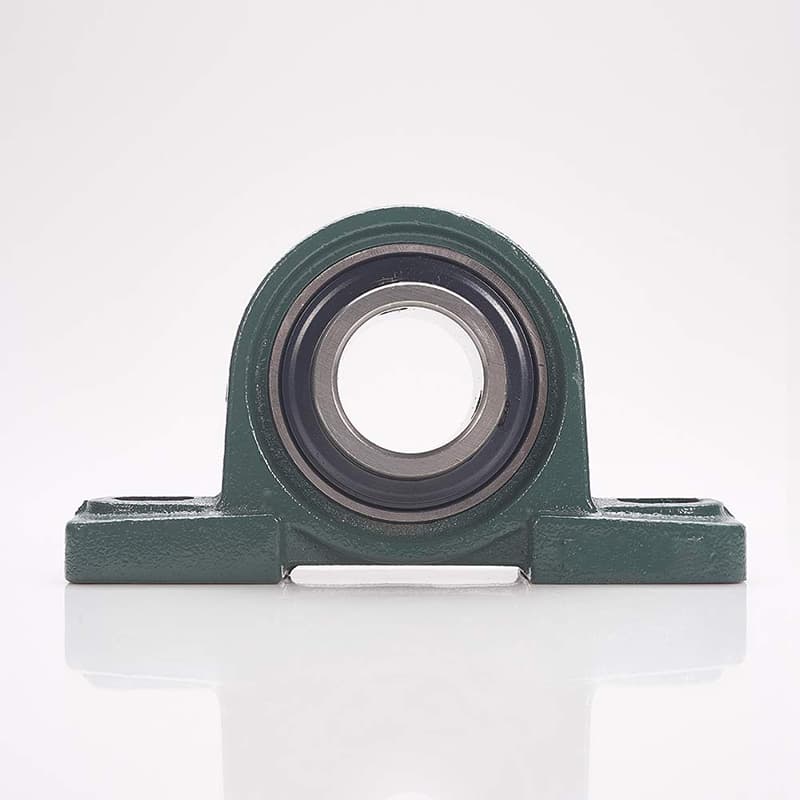

At FYTZ, we produce pillow block bearings with these high-temperature configurations. We can advise our distributors on the right specification for their customer’s specific heat challenge, moving from a generic product to a targeted solution.

What is the SKF 6204 high temperature bearing?

Many customers mention "SKF 6204 HT1" as a benchmark. It represents a common approach to the high-temperature problem. It is not a magical product, but a specific recipe of materials for a specific temperature range.

The SKF 6204 high-temperature bearing2 is a deep groove ball bearing with a 20mm bore. Its "HT" designation typically means it features heat-stabilized rings3 (for temps up to 250°C), a brass cage4, and is filled with a high-temperature polyurea grease5. It serves as a common upgrade for hot applications.

Deconstructing a Benchmark: What "HT" Really Means

The SKF 6204 HT1 is a good example to understand the industry’s standard response to moderate high temperatures. Let’s break down what "HT" covers and, just as importantly, what it does not cover.

1. The "6204" Part: Size and Basic Type

- 6: Deep Groove Ball Bearing series.

- 204: Bore diameter code. 04 x 5 = 20mm bore. It is a common, small-to-medium size.

2. The "High Temperature" (HT) Modifications:

- Heat-Stabilized Rings: The bearing rings undergo an extra thermal stabilization process after hardening. This reduces the risk of dimensional change and loss of hardness when exposed to temperatures up to 250°C for short periods (likely 150-180°C continuous).

- Brass Cage: Replaces a standard steel or polymer cage. Brass can withstand the heat without losing strength or melting.

- High-Temperature Grease: The bearing is pre-lubricated with a synthetic grease, often polyurea-based, with a high dropping point (e.g., >250°C) and good oxidation stability for the temperature range.

3. Important Limitations and Considerations:

- It’s Still a Deep Groove Ball Bearing: It is designed for radial and some axial load, but not for heavy loads or misalignment. For a pillow block on a kiln, a spherical roller bearing type might be more suitable for load and alignment.

- Temperature is a Range: "Up to 250°C" is a peak, not a recommended continuous operating temperature. Continuous operation is likely 30-50°C lower.

- Lubrication Life is Finite: Even high-temp grease degrades. Relubrication intervals are drastically shortened compared to room-temperature service.

- Clearance: High-temperature versions often come with increased radial internal clearance (C3 or C4) to account for thermal expansion of the inner ring on the shaft.

For a B2B supplier like FYTZ, we have our own equivalent products. We understand that when a customer asks for an "SKF 6204 HT1," they are asking for a set of performance characteristics, not just a brand. We can provide our FYTZ 6204 E (for Enhanced/High-Temp) bearing with the same key features: stabilized steel, brass cage4, and high-temp grease. This allows distributors like Rajesh’s company to offer a reliable, cost-effective alternative for their customers in price-sensitive markets like India or Bangladesh. We compete on providing the same material solution with competitive pricing and reliable supply.

What is the operating temperature1 of a pillow block bearing?

There is no single answer. The operating temperature1 limit depends entirely on the materials inside the bearing unit, not just the cast iron or steel housing. The housing can handle more heat than the bearing inside.

The operating temperature1 of a pillow block bearing is determined by its internal bearing2‘s limits. Standard units are typically rated for -30°C to +120°C. High-temperature pillow blocks, with special bearings and seals, can operate continuously from 150°C to 200°C, with peak ratings up to 250°C or more for short periods.

The Chain of Weakest Links in a Hot Environment

A pillow block is a system. Its operating temperature1 is the lowest maximum temperature any one of its critical components can handle. You must check each link in the chain.

1. The Internal Bearing (The Core Limiter)

As discussed, this is the primary limit. Its temperature rating comes from:

- Steel stabilization level.

- Cage material.

- Initial lubricant type and quantity.

2. The Sealing System (A Critical Failure Point)

Seals keep grease in and dirt out. Heat destroys them.

- Standard Nitrile Rubber (NBR) Seals/Lip Seals: Start to harden, crack, and lose elasticity above 100-120°C.

- High-Temperature Seals: Made from Fluoroelastomer (FKM/Viton) or Silicone. These can withstand 200°C to 250°C continuous, protecting the lubricant inside.

3. The Housing

- Gray Cast Iron (Standard): Good for most industrial temps, but can experience growth and distortion above 300-400°C.

- Ductile Iron or Steel: Better strength at higher temperatures.

- Phenomenon of Heat Soak: The housing can get much hotter than the ambient air, especially if it is in an enclosed hot space. The bearing inside will be hotter than the housing surface you measure with a thermometer.

4. The Shaft Fit and Expansion

This is a hidden danger. As the shaft heats up, it expands. A bearing with a standard fit (tight on the shaft) can have its internal clearance eliminated by this expansion, leading to preload, friction, and overheating. High-temperature applications often require a looser initial fit (like g6 instead of h6) to account for this.

Practical Temperature Assessment:

To determine if a pillow block is suitable, you must know:

- Ambient Air Temperature around the housing.

- Radiation Heat from nearby surfaces (like an oven wall).

- Internal Heat Generation from the bearing itself due to friction (higher at high speeds/loads).

The Bearing Operating Temperature = Ambient + Radiation + Frictional Heat. This is often 10-30°C hotter than the air around the housing.

For maintenance planners and distributors, this systemic view is essential. When a customer says their oven runs at 180°C, you must ask: "Is that the air temperature or the bearing housing temperature?" Recommending a high-temp pillow block requires specifying not just a "high-temp bearing," but also high-temp seals (Viton) and guidance on shaft fit3 tolerances. Providing this complete package is how FYTZ and our partners deliver real solutions, not just parts.

What are the different types of pillow block bearings?

Pillow blocks come in many shapes and sizes. Choosing the wrong type for a high-temperature application guarantees failure. The housing design must support the bearing’s fight against heat, not hinder it.

The main types of pillow block bearings are classified by the internal bearing type: Ball Bearing Units (for lighter loads), Spherical Roller Bearing Units (for heavy loads and misalignment), Tapered Roller Bearing Units (for combined loads), and CARB Toroidal Roller Bearing Units (for high misalignment). Housing designs include split (two-bolt, four-bolt) or solid.

Matching the Pillow Block Type to the High-Temperature Challenge

The choice of type affects lubrication, heat dissipation, and load handling—all critical in hot environments. A spherical roller bearing unit is often the best choice for industrial dryers and kilns, but you need to know why.

1. By Internal Bearing Type:

-

Ball Bearing Pillow Blocks (e.g., with 6204 bearing):

- Best for: Light to moderate radial loads, high speeds.

- High-Temp Consideration: Limited load capacity. Heat generation from high speed can be an issue. Often used on fan shafts in hot air streams.

-

Spherical Roller Bearing Pillow Blocks (e.g., with 222 series bearing):

- Best for: Very heavy radial loads, moderate misalignment, moderate speeds. This is the most common choice for dryers, kilns, and large ovens because it handles the load and the inevitable frame expansion/misalignment.

- High-Temp Consideration: Robust design. Can be supplied with high-temp specs (stabilized steel, brass cage, C4 clearance). The spherical roller is the workhorse of hot, heavy industry.

-

Tapered Roller Bearing Pillow Blocks:

- Best for: Applications with high combined radial and axial (thrust) loads.

- High-Temp Consideration: More complex to adjust. Thermal expansion can affect preload setting critically.

-

CARB Toroidal Roller Bearing Pillow Blocks:

- Best for: Extremely high misalignment and axial movement.

- High-Temp Consideration: A specialized solution, not typically the first choice for standard high-temp apps.

2. By Housing Design & Features:

- Split Housing vs. Solid Housing: Split housings (two-part) are much easier to install and inspect, especially on long, fixed shafts in confined hot spaces. This is a major advantage for maintenance.

- Eccentric Locking Collar vs. Set Screw vs. Adapter Sleeve: The locking mechanism matters.

- Eccentric Collar: Common, secure, but can be hard to loosen after exposure to high heat and corrosion.

- Adapter Sleeves: Provide a very secure fit and are easier to remove, often preferred for heavy-duty, high-temp applications.

Selecting for High-Temperature Service:

The goal is to choose a type that minimizes internal heat generation and maximizes heat tolerance.

| Application Example | Recommended Pillow Block Type | Key High-Temp Reasoning |

|---|---|---|

| Conveyor in Drying Oven (Moderate Load, Misalignment) | Split Housing, Spherical Roller Bearing Unit | Handles frame expansion (misalignment) and load. Split housing allows easy replacement. |

| Fan Shaft in Hot Air (High Speed, Light Load) | Solid Housing, Ball Bearing Unit (High-Temp Spec) | Sufficient for load, high-temp grease handles speed-generated heat. |

| Heavy Kiln Tire Support Roller (Very Heavy Load, Low Speed) | Solid Housing, Spherical Roller Bearing Unit (Extra Heavy-Duty) | Maximum load capacity. Low speed reduces friction heat; primary heat is external. |

For FYTZ and our global distributors, this knowledge enables precise matching. When a manufacturer in Turkey is building a new dryer, Rajesh’s company can propose the optimal FYTZ spherical roller pillow block with high-temp features, not just a generic unit. This consultative approach wins business and builds partnerships based on technical expertise and reliable performance in tough conditions.

Conclusion

Selecting a high-temperature pillow block bearing requires a system-wide view: heat-stable internals, robust seals, correct fit, and the right housing type. This holistic approach is the key to reliability in the demanding heat of dryers, kilns, and ovens.

-

Understanding the operating temperature range is crucial for selecting the right bearing for your application. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the key factors that influence the temperature limits of internal bearings. ↩ ↩ ↩

-

Explore the importance of shaft fit in preventing overheating and ensuring optimal bearing performance. ↩ ↩ ↩

-

Find out why brass cages are preferred in high-temperature bearings and their benefits over other materials. ↩ ↩ ↩

-

Learn about high-temperature polyurea grease, its properties, and why it’s essential for high-performance bearings. ↩ ↩

-

Find out how Solid Lubricants work and their importance in extreme temperature bearing applications. ↩

-

Understand the significance of C4/C5 clearance in high-temperature bearings for optimal performance. ↩

-

Discover the role of Cooling Systems in maintaining bearing performance under extreme heat. ↩