Receiving a container of bearings only to find quality issues is a costly nightmare for importers. It means delays, arguments with suppliers, and lost sales. A proactive inspection plan before shipment is your best defense, turning a risky import into a reliable supply chain partnership.

Before shipment from China, inspect deep groove ball bearings for dimensional accuracy (bore, OD, width), radial clearance, surface finish (no cracks, rust), noise/vibration levels, packaging, and marking. Also verify the HS code (e.g., 8482.10) for customs. A proper inspection ensures you receive bearings that match your specifications and perform as expected.

Waiting until the goods arrive at your port to check quality is too late. Effective inspection requires knowing what to check, how to check it, and what standards to reference. This knowledge empowers you to work with your supplier to ensure quality, from understanding customs codes to verifying critical physical properties. Let’s build a practical inspection checklist.

What is the HS code for deep groove ball bearings?

An incorrect HS code can derail your entire shipment. Customs delays, unexpected duties, and storage fees eat into profits. Using the precise code is a fundamental step in professional international trade, not just bureaucracy.

The HS (Harmonized System) code for deep groove ball bearings is 8482.10. This is the international heading. The full code may vary by country; for example, China’s export code for deep groove ball bearings with an outer diameter not exceeding 30mm is 8482.1010, while those exceeding 30mm are 8482.1090. Accurate coding ensures smooth customs clearance1 and correct tariff application2.

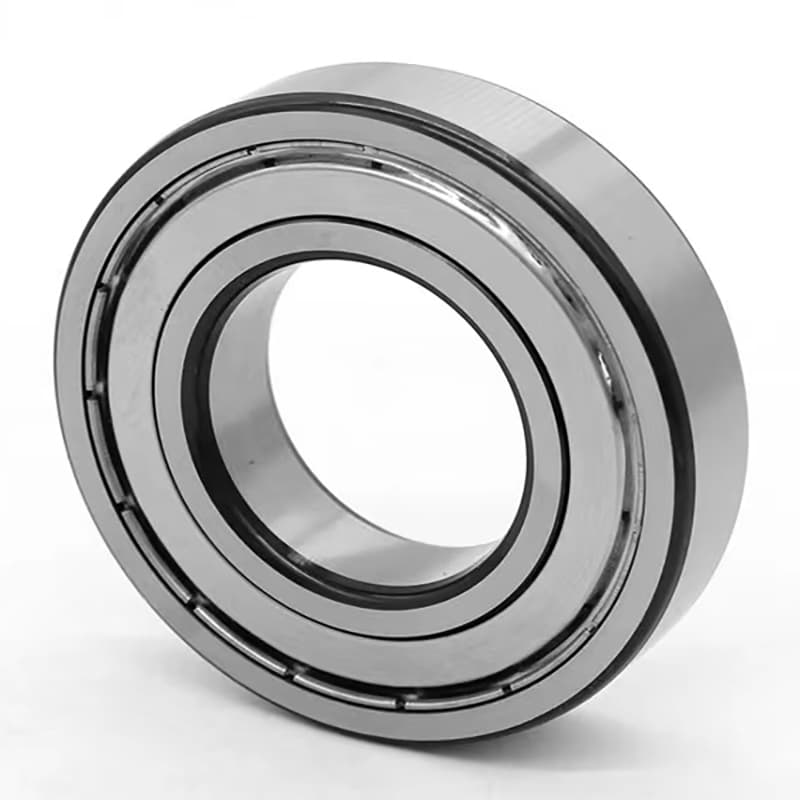

[^3] 8482.10](https://sdycbearing.com/wp-content/uploads/2025/12/Deep-Groove-Ball-Bearing-40.jpg)

Navigating Customs Classification for Smooth Logistics

The HS code3 is a universal language for traded goods. For bearing importers, using the correct code based on size is a critical logistical skill. It affects your landed cost and the speed at which your goods clear customs.

Understanding the Code Structure:

Let’s break down 8482.1090 (a common code for bearings >30mm OD from China):

- 84: Section – "Nuclear reactors, boilers, machinery and mechanical appliances; parts thereof."

- 8482: Heading – "Ball or roller bearings."

- 8482.10: Sub-heading – "Ball bearings."

- 8482.1090: National Tariff Line – In many systems, this specifies "Other ball bearings" often interpreted as deep groove and other single-row types exceeding a certain size threshold (commonly 30mm outer diameter).

Why Size Matters in Classification:

Many customs authorities differentiate between miniature/small bearings and larger industrial bearings, often at the 30mm outer diameter (OD) threshold. This is because their manufacturing processes, applications, and sometimes duty rates can differ.

| Bearing Type & Size | Example HS Code (China Export) | Notes |

|---|---|---|

| Deep Groove Ball Bearing, OD ≤ 30mm (e.g., 608, 6203) | 8482.1010 | For miniature/small bearings. |

| Deep Groove Ball Bearing, OD > 30mm (e.g., 6205, 6305) | 8482.1090 | For most standard industrial sizes. |

| Angular Contact Ball Bearing | 8482.20 | Different sub-heading. |

| Tapered/Spherical Roller Bearing | 8482.30/8482.40 | Different sub-headings. |

Inspection Point Related to HS Code:

During your pre-shipment inspection, you should verify the commercial invoice and packing list against the physical goods.

- Check the bearing size: Measure the outer diameter of a sample from the batch. Is it above or below 30mm?

- Verify the declared HS code3 on the supplier’s documents matches the actual product (deep groove ball bearing4) and its size.

- Confirm the description is accurate (e.g., "Deep Groove Ball Bearing 6205-2RS").

Getting this right prevents problems at customs. A professional supplier like FYTZ will always provide the correct HS code3 on our documents. For an importer like Rajesh, providing his customs broker with the accurate HS code3 (8482.1090 for his typical orders of 6205 bearings) ensures his shipments clear Mumbai port efficiently, avoiding demurrage and keeping his supply chain predictable.

What are the properties of deep groove ball bearings?

Inspecting a bearing without knowing its key properties is like checking a car without knowing how the engine should sound. You need to know what "good" looks and feels like to identify "bad." These properties are your inspection criteria.

The key properties of deep groove ball bearings include dimensional accuracy (bore, OD, width)1, radial internal clearance (C0, C2, C3, etc.)2, dynamic and static load ratings (C, C0)3, limiting speed, running accuracy (vibration/noise level)4, material hardness, and surface finish. These properties determine the bearing’s performance, life, and suitability for specific applications.

The Inspection Checklist: From Datasheet to Physical Verification

These properties are not just numbers in a catalog; they are measurable attributes you or a third-party inspector can verify against the supplier’s specifications and international standards (like ISO 199 for tolerances, ISO 281 for load ratings).

Here is a breakdown of inspectable properties and how to approach them:

1. Dimensional Accuracy (The Foundation):

- What to Check: Bore diameter (d), Outer diameter (D), Width (B or C).

- How to Inspect: Use calibrated micrometers, bore gauges, and height gauges. Measure multiple points on multiple bearings from the batch.

- Standard Reference: ISO 199 (Tolerances)5. Check against the specified tolerance class (e.g., Normal/P0, P6, P5). For a 6205 bearing, the bore should be 25.000mm with a tolerance of +0/-0.01mm or similar.

2. Radial Internal Clearance:

- What to Check: The amount of free movement between the inner and outer rings in the radial direction. This is crucial for fit and thermal expansion.

- How to Inspect: Can be measured with a dial indicator on a special fixture. For a basic check, you can feel for excessive play by hand, but this is not precise.

- Standard Reference: The bearing should be supplied in the clearance group ordered (e.g., C0 Normal, C3). This must match your application needs.

3. Running Accuracy (Vibration/Noise):

- What to Check: Smoothness of rotation. Excessive vibration indicates internal imperfections like poor raceway finish, ball size variation, or contamination.

- How to Inspect: The best method is a vibration tester (accelerometer). For a practical check, mount the bearing on a clean mandrel, spin it by hand or air, and listen/feel. It should spin freely and quietly with no grating or rumbling sounds. A high-precision bearing (P5) will feel noticeably smoother than a P0 bearing.

4. Material Hardness and Surface Finish:

- What to Check: Raceway and ball surface for cracks, rust, pitting, or grinding burns. General hardness.

- How to Inspect: Visual inspection under good light is first. Look for any discoloration (blue/brown from overheating), rust spots, or scratches. Use a portable hardness tester (Rockwell) on a non-functional surface if possible.

- Standard: Surfaces should be smooth and shiny, free of defects. The material should be hard (typically 58-64 HRC for through-hardened steel).

5. Marking and Packaging:

- What to Check: Are the bearings clearly marked with brand, size, and origin? Is the packaging clean, robust, and anti-rust (oil paper, vacuum packing)?

- Why it matters: Proper marking ensures traceability. Good packaging prevents corrosion during sea transit.

At FYTZ, our integrated inspection line checks these properties automatically. When a client asks for an inspection report before shipment, we can provide data on dimensions, vibration, and noise from our in-process tests. This transparency builds trust. For an importer, specifying that bearings must meet, for example, "ISO P6 tolerance and have a vibration level below VA405" gives you concrete, inspectable criteria to hold the supplier to.

What is the axial clearance of a deep groove ball bearing?

This is a common point of confusion. Deep groove ball bearings are designed for radial load, and their internal geometry does not have a defined, adjustable "axial clearance" in the same way as a tapered roller bearing. However, they do have axial play, which is a result of their radial clearance and groove design.

Deep groove ball bearings do not have a standardized axial clearance specification like radial clearance groups (C3). The axial internal clearance is typically 2 to 10 times the radial internal clearance1, depending on the bearing size and internal design. It is a derived value, not a primary design parameter. Excessive axial play can indicate incorrect radial clearance2 or wear.

Understanding Axial Play: A Consequence, Not a Control

Inspectors sometimes check axial play by pushing and pulling the inner ring. While this can give a rough indication of bearing condition, it’s important to understand what you’re measuring and what is acceptable.

Why Axial Play Exists:

The deep groove allows the balls to move along the raceway. When you apply an axial force, the balls roll slightly up the incline of the groove. The amount they can move axially before the contact angle changes significantly is the axial play. It is directly related to the radial clearance2 and the conformity (curvature) of the raceway.

How to Check It (For Informational Purposes):

- Fix the outer ring.

- Use a dial indicator on the side face of the inner ring.

- Push and pull the inner ring axially and note the total movement.

This value is not typically found on a datasheet but can be compared between samples from the same batch for consistency.

What Abnormal Axial Play Might Indicate:

- Excessive Axial Play3: Could mean the radial internal clearance1 is too large (e.g., a C4 bearing mistaken for C0, or a worn bearing). This can lead to vibration and noise under axial load.

- Very Little or No Axial Play: Could mean the bearing has insufficient radial clearance2 or has been preloaded (damaged). This causes high friction and overheating.

Inspection Focus for Deep Groove Bearings:

For deep groove ball bearings, the primary and standardized specification is Radial Internal Clearance (RIC). Your inspection should focus on verifying the RIC group (C0, C3, etc.) as agreed in the order. Checking axial play can be a supplementary, quick check for gross abnormalities or consistency within a batch, but it should not replace verification of radial clearance2.

Example for an Inspector:

If you order 6205 bearings with C3 radial clearance4e](https://ntnamericas.com/newsletter/the-importance-of-radial-clearance-when-installing-spherical-roller-bearings/)[^2], you should ensure the supplier’s inspection report confirms the RIC is within the C3 range per ISO standards. You can then do a simple axial play check on several samples. If they all feel similar, it’s likely consistent. If one feels drastically looser axially, it warrants a closer look at its radial clearance2.

For our clients, we specify and control the radial clearance2. We understand that axial capability comes from the deep groove design itself. If a client has a specific need for controlled axial movement, we might discuss alternative bearing types like double-row angular contact bearings5 which are designed for axial stiffness. This technical clarity during the ordering process prevents misunderstandings during inspection.

What is the difference between standard and deep groove ball bearing1s?

This phrasing is misleading but very common. In reality, "deep groove ball bearing1" is the standard, most common type. The confusion usually arises between standard precision deep groove bearings2 and high-precision deep groove bearings3, or between deep groove and other types like angular contact bearings4.

There is no category called "standard bearings" distinct from deep groove. The deep groove ball bearing1 is the standard bearing. The confusion often refers to the difference between standard precision (Normal/P0) deep groove bearings and high-precision (P5, P6, ABEC 5, 7) deep groove bearings, or to the difference between deep groove and other designs like angular contact or self-aligning ball bearings.

Clarifying Terminology for Accurate Inspection

As an inspector, you must know exactly what was ordered. Did the buyer order "deep groove ball bearing1s" or did they specify a particular type like "angular contact"? Did they order "standard" (meaning P0) or "P5 precision"? The packing list and product must match.

Scenario 1: "Standard" vs. High-Precision Deep Groove Bearings.

This is a difference in tolerance class5, not bearing type. Both are deep groove ball bearing1s.

- Order Says: "Deep Groove Ball Bearing 6205, Standard."

- Likely Means: 6205 bearing with Normal (P0) tolerance.

- Inspection Focus: Verify dimensions are within the wider P0 tolerance bands. Vibration/noise may be higher.

- Order Says: "Deep Groove Ball Bearing 6205, P5 Precision."

- Inspection Focus: Must verify tighter P5 tolerances and likely lower vibration levels. This often requires more sensitive equipment.

Scenario 2: Deep Groove vs. Other Ball Bearing Types.

This is a difference in bearing design and function6.

- Deep Groove Ball Bearing: Symmetrical, deep grooves. Handles radial and bilateral axial load.

- Angular Contact Ball Bearing: Asymmetric grooves with higher shoulders on one side. Designed primarily for high axial load in one direction. Often used in pairs.

- Self-Aligning Ball Bearing: Spherical outer ring. Handles misalignment, not high axial load.

Inspection Point – Visual Identification:

An inspector must be able to tell them apart:

- Deep Groove: Look into the bearing. The grooves on both rings look the same, deep and symmetrical.

- Angular Contact: The grooves are not symmetrical. One side of the groove has a visibly higher shoulder than the other.

Why This Matters for Your Shipment:

Receiving angular contact bearings4 when you ordered deep groove bearings (or vice versa) is a major error. They are not interchangeable. The machine will likely fail.

Inspection Action Table:

| If The Order Specifies… | Then During Inspection, Verify… | Critical Check |

|---|---|---|

| "Deep Groove Ball Bearing 6205-2RS" | Dimensions, presence of two rubber seals (2RS), deep symmetrical grooves. | Correct type and sealing. |

| "Deep Groove Ball Bearing 6205 P5" | Dimensions are within tighter P5 limits (may need gauge report). Running smoothness. | Precision class compliance. |

| "Angular Contact Bearing 7205" | Asymmetric raceways, marking (7205, not 6205). | Not a deep groove bearing. |

At FYTZ, we are precise in our communications. We will confirm: "You need 6205 deep groove, P5 precision, with C3 clearance, correct?" This avoids ambiguity. For an importer doing inspection, the first step is to pull the purchase order and confirmed specifications, then check the physical bearing and its markings against that document. A bearing marked "6205" is a deep groove. A bearing marked "7205" is angular contact. This simple check can catch a costly supplier error before the container is sealed.

Conclusion

Effective pre-shipment inspection of deep groove ball bearings from China requires verifying key properties (dimensions, clearance, finish) against the order spec, distinguishing between precision grades, confirming the correct HS code (8482.10), and ensuring the bearing type (deep groove vs. angular contact) is correct to avoid costly receiving errors.

-

Explore this link to understand the most common type of bearing and its applications. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the characteristics of standard precision bearings and their uses in various industries. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the advantages of high-precision bearings for better performance in machinery. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Find out how angular contact bearings differ from deep groove bearings and their specific applications. ↩ ↩ ↩ ↩ ↩

-

Explore the importance of tolerance classes in ensuring the right fit and function of bearings. ↩ ↩ ↩

-

Learn about various bearing designs and their specific functions to make informed choices. ↩