Choosing the wrong pillow block type for your shaft system is a fundamental design error. A fixed unit on a long conveyor can cause binding and premature failure as the shaft expands with heat. An adjustable unit where it’s not needed adds cost and complexity without benefit, wasting your budget.

Fixed pillow blocks provide rigid, non-movable support and are used for precise shaft positioning. Adjustable (or "floating") pillow blocks, like take-up units, allow linear movement to accommodate thermal expansion or belt/chain tensioning. The choice depends on the need for shaft stability versus the need to manage dimensional changes or tension.

This choice affects more than just installation; it dictates the long-term reliability and maintenance needs of your entire machine. Understanding the difference, along with the common pitfalls and load considerations for pillow blocks, is essential for making an informed purchase that balances performance, cost, and durability. Let’s break down the key factors.

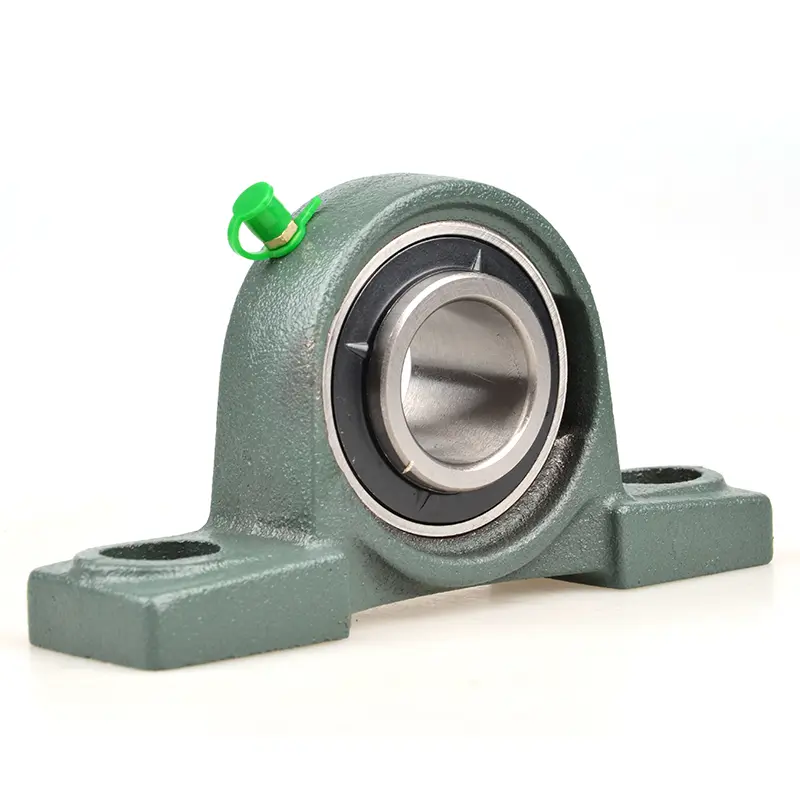

What is the difference between fixed and floating pillow block1 bearings?

Many people think all pillow blocks are the same—they just bolt down. This misunderstanding leads to machines that fight against natural forces like thermal expansion2, creating stress, wear, and unexpected breakdowns.

The key difference is in their mounting and function. A fixed pillow block3 is bolted securely in place and does not allow the bearing housing to move. It provides fixed, rigid support. A floating (or adjustable) pillow block is mounted in a way that allows the housing to slide or adjust linearly along the shaft’s axis. This accommodates thermal expansion2 of the shaft or is used for tensioning belts/chains.

The Mechanics of Constraint vs. Accommodation

The terms "fixed" and "floating" refer to the bearing’s ability to move axially relative to the machine frame. This is a critical design decision that affects how the entire shaft system handles real-world physical changes.

Fixed Pillow Block Bearings:

- Design: The housing is fastened directly to the machine frame with bolts through fixed holes. The bearing inside (often a deep groove ball bearing or cylindrical roller bearing) may have a fixed fit on the shaft (e.g., with set screws or an interference fit).

- Function: It locates the shaft axially. It prevents the shaft from moving along its length at that point. In a typical two-bearing shaft system4, one end uses a fixed bearing to control axial position.

- Consequence: If the shaft expands due to heat (from friction, process heat, or environment), it can only expand away from the fixed point. If there is no accommodation for this expansion, it creates axial compressive stress5 in the shaft and axial load on the fixed bearing, which it may not be designed to handle.

Floating (or "Non-Locating") Pillow Block Bearings:

- Design: The bearing inside is designed to allow axial movement6. This can be achieved in two ways:

- Bearing Type: Using a bearing that allows internal axial slip, like a "Cylindrical Roller Bearing7" (NU, NJ types) in its housing. The rollers can move axially within the housing.

- Housing Design: Using a standard bearing in an "adjustable" or "take-up" housing. This housing has elongated bolt holes or a sliding base, allowing the entire unit to be moved and locked in different positions.

- Function: It supports radial load but allows free axial shaft movement. It accommodates thermal expansion2 and contraction without inducing stress.

- Standard Practice: In a simple two-bearing shaft, the standard arrangement is one fixed bearing and one floating bearing. The fixed bearing sets the axial position; the floating bearing allows for expansion.

Here is a decision guide for a simple shaft:

| If Your Shaft Application… | Recommended Pillow Block Arrangement | Reason |

|---|---|---|

| Is very short and runs cool | Two fixed bearings can sometimes be used. | Thermal expansion is negligible. |

| Is long, runs hot, or experiences temperature changes | One fixed bearing, one floating bearing. | Essential to prevent destructive axial forces from thermal expansion2. |

| Requires tension adjustment (conveyor, chain drive) | Use an adjustable take-up unit8 as the floating end. | Allows for precise positioning to set and maintain tension. |

For our clients who are conveyor manufacturers in Indonesia or fan OEMs in the Middle East, this is basic but critical knowledge. We guide them to specify the correct combination. At FYTZ, we supply both types: standard fixed pillow block3s (UCP series) and adjustable take-up unit8s. For Rajesh, the distributor, understanding this helps him ask the right questions when a customer needs a replacement. He can ask, "Is this the end that moves for adjustment or the fixed end?" This ensures he sells the correct part and prevents a callback.

What are the common problems with pillow blocks?

Pillow block failure is rarely random. It follows predictable patterns based on the type of unit, its installation, and the environment. Recognizing these patterns helps buyers select better products and implement better maintenance, avoiding costly downtime.

Common problems with pillow blocks include misalignment causing uneven load and premature bearing wear1, seal failure leading to contamination ingress2, improper lubrication3 (over/under greasing, wrong grease type), corrosion from harsh environments4, and loose mounting bolts causing fretting and vibration5. These issues are often interrelated and stem from incorrect selection, installation, or maintenance.

A Proactive Approach: From Symptom to Prevention Strategy

Understanding common problems is the first step toward prevention. Each problem has a root cause that can often be addressed at the point of selection or through proper procedures. Let’s analyze the top issues and link them back to the buyer’s decisions.

1. Misalignment (Angular or Parallel):

- Symptom: Noisy operation, localized wear on the bearing raceway, overheating, short bearing life.

- Root Cause: Machine frame not flat or parallel, shims not used during installation, shaft deflection under load.

- Buyer’s Defense: Select self-aligning pillow blocks6. These use spherical roller bearings or ball bearings with spherical outer surfaces that pivot inside the housing, compensating for several degrees of misalignment. This is one of the most valuable features for real-world installations.

2. Seal Failure and Contamination:

- Symptom: Grease leaking (often discolored), gritty feeling when turning the shaft, rapid bearing wear.

- Root Cause: Inadequate seal for the environment (e.g., single lip in a dusty area), seal damaged during installation, chemical attack from cleaners.

- Buyer’s Defense: Specify the correct seal type for the environment. For dust, use contact seals (RS). For heavy dust/washdown, use triple-lip seals or labyrinth seals7. Ensure the seal material is compatible with any chemicals present.

3. Lubrication Issues:

- Symptom: Bearing seizure, discoloration from overheating, grease leaking or hardened.

- Root Cause: Over-greasing (pressure builds and blows out seals), under-greasing, using the wrong grease (e.g., standard grease in high heat or water washdown).

- Buyer’s Defense: Understand the application. For high-temperature or washdown, specify blocks pre-packed with high-temperature or water-resistant grease. For maintenance, train staff on proper purge re-lubrication techniques.

4. Corrosion:

- Symptom: Rust on housing, bolts, and shaft. Leads to seizure and difficulty in disassembly.

- Root Cause: Using standard cast iron or steel in humid, wet, or chemical environments.

- Buyer’s Defense: Specify corrosion-resistant materials8. Choose stainless steel housings (AISI 304/316) for severe environments, or plated cast iron (nickel, zinc) for moderate conditions. This is a critical upfront cost that saves many times over in replacement and downtime.

5. Loose Mounting and Fretting:

- Symptom: Vibration, elongated bolt holes, wear patterns under the housing base.

- Root Cause: Insufficient bolt torque, poor frame surface, vibration.

- Buyer’s Defense: Ensure mounting surfaces are flat and clean. Use proper torque when installing. For high-vibration applications, consider units with four-bolt bases for greater stability vs. two-bolt bases.

At FYTZ, we design our products to mitigate these issues. We offer self-aligning spherical roller bearing blocks, housings with multiple seal options, and different material grades. When a client in the mining sector in South Africa has problems with contamination and misalignment, we recommend our heavy-duty block with spherical rollers and labyrinth seals. Solving these common problems through better initial selection is a core part of the value we provide to our B2B partners.

What bearings are best for heavy loads?

Putting a deep groove ball bearing in a heavily loaded conveyor head pulley is asking for rapid failure. Its point contact cannot distribute the load, leading to plastic deformation (brinelling) and early fatigue. The bearing type inside the pillow block must match the load profile.

For pillow block applications1 with very heavy radial loads, spherical roller bearing inserts2 are the best choice. They provide the highest radial load capacity due to line contact, can handle moderate axial loads and significant misalignment. For extremely high pure radial loads with no misalignment, cylindrical roller bearing inserts3 are also excellent but are more sensitive to installation.

Matching Bearing Insert Technology to Load Demand

The "best" bearing for heavy loads depends on the nature of the load (radial, axial, shock), the presence of misalignment, and the speed. The pillow block housing is just a container; the bearing insert inside does the actual work.

1. Spherical Roller Bearings (The Heavy-Duty Champion):

- Load Profile: Exceptional radial load capacity, good axial load capacity in both directions.

- Key Feature: Self-Alignment. This is critical in heavy machinery where housings can distort under load or frames are not perfectly aligned. It prevents destructive edge loading.

- Pillow Block Use: The premier choice for mining conveyors, vibrating screens, crushers, large fans, and heavy industrial gearboxes. Their robust design handles shock loads well.

2. Cylindrical Roller Bearings (The Pure Radial Workhorse):

- Load Profile: The highest pure radial load capacity of all common bearing types.

- Key Feature: No inherent axial load capacity (unless specifically designed with flanges). Allows free axial shaft movement, making them ideal for the floating end of a shaft.

- Pillow Block Use: Excellent for the non-locating end of long shafts in heavy equipment, or in applications like rolling mills where radial load is immense and axial movement must be free.

3. Tapered Roller Bearings (For Combined Loads with Precision):

- Load Profile: High combined radial and axial load capacity (primarily one direction).

- Key Feature: Can be preloaded for high rigidity. Often used in pairs.

- Pillow Block Use: Common in heavy vehicle wheel ends and some gearboxes. Less common in general industrial pillow blocks due to need for precise adjustment and pairing.

Comparison for heavy-load pillow block selection:

| Bearing Insert Type | Radial Load | Axial Load | Misalignment Tolerance | Best Pillow Block Application |

|---|---|---|---|---|

| Spherical Roller | Very High | Good (Both Directions) | Excellent (2-3°) | Heavy, dirty, misaligned applications (e.g., aggregate conveyor). |

| Cylindrical Roller | Highest (Pure Radial) | Very Low | Poor (Nearly 0°) | Floating end of long, heavily loaded shafts (paper machine rolls). |

| Deep Groove Ball | Moderate | Moderate (Both Directions) | Poor | Not for heavy loads. For general purpose, lighter duty. |

For a buyer, this means looking beyond the housing. When sourcing a pillow block for a cement plant stacker reclaimer, you must specify a block with a spherical roller bearing insert. At FYTZ, we produce these as complete units. Our heavy-duty series features a rugged cast iron housing matched with a high-capacity spherical roller bearing, designed as a system. This ensures our distributors can provide a reliable solution for the most demanding applications their customers face.

Which is better ball bearing or sliding bearing?

This is a fundamental choice in machine design. Using a sliding (plain) bearing where speeds are high leads to rapid wear and overheating. Using a rolling (ball) bearing where loads are shock-intensive or where lubrication is impossible can lead to brinelling or seizure. Each has its domain.

There is no universal "better"; each has ideal applications. Ball (rolling) bearings1 are better for most industrial applications requiring low friction, moderate to high speed, and precise operation2 with manageable loads. Sliding (plain) bearings3 are better for very high load, low speed, shock load, or oscillating motion applications4, and where simplicity or embedded lubrication is needed.

The Friction Divide: Rolling vs. Sliding Contact

The core difference is the physics of friction. Ball bearings use rolling friction5, which is very low. Sliding bearings use sliding friction, which is higher and requires a maintained lubricant film to prevent metal-to-metal contact. This fundamental difference dictates their entire performance profile.

Ball Bearings (in a Pillow Block):

- Advantages:

- Low Starting and Running Friction: Efficient, less heat generation.

- Precision and Low Clearance: Allow for accurate shaft positioning.

- Handles Combined Loads: Deep groove types handle some axial and radial load.

- Standardization: Widely available in standard sizes and types.

- Disadvantages:

- Limited Shock Load Capacity: Point/line contact can brinell (dent) under heavy impact.

- More Complex: More parts (rings, balls, cage, seals).

- Require Precise Lubrication: Depend on specific grease or oil.

- Best For: Electric motors, conveyors, fans, pumps, gearboxes—most general industrial machinery.

Sliding Bearings (Plain Bushings, often not in a "pillow block" format):

- Advantages:

- High Load Capacity6: Load is distributed over a large area.

- Excellent Shock Load Resistance: Conformal contact absorbs impact.

- Simpler Design: Often just a sleeve of material.

- Quieter: No rolling elements to cause noise.

- Can be Self-Lubricating: Made from materials like bronze, graphite, or PTFE composites.

- Disadvantages:

- Higher Friction: Especially at start-up (boundary lubrication).

- Requires Continuous Lubrication (unless self-lubricating7) for high loads/speeds.

- Wear Over Time: Clearance increases, affecting precision.

- Best For: Heavy, slow oscillating motion (construction equipment linkages), journal bearings in engines/turbines, applications with embedded lubrication or where maintenance is difficult.

Decision Matrix for a Pillow Block Context:

| If Your Application Needs… | Choose a Pillow Block with… | Why? |

|---|---|---|

| Efficiency, Speed, and Precision | Ball Bearing or Roller Bearing Insert. | Rolling friction enables this performance. |

| To Handle Massive, Steady Loads at Low Speed | A Hydrodynamic Sliding Bearing (specialized). | Large surface area supports the load with an oil film. |

| To Handle Severe Shock Loads in Dirty Conditions | Possibly a Heavy-Duty Spherical Roller Bearing8 or, in some cases, a self-lubricating7 bushing. | Roller bearings handle shock well; bushings are simple and durable if speed is low. |

| Simple, maintenance-free operation in a low-load, low-speed pivot | A plain bearing bushing unit (not a rolling bearing pillow block). | No need for grease re-lubrication; lower cost. |

For our business at FYTZ, we focus on rolling bearing pillow blocks because they address the vast majority of industrial power transmission needs. When a client designing agricultural equipment has a linkage with pure oscillating motion, we might acknowledge that a bushing is better for that specific joint. But for the main driveline and rotating shafts, we provide the superior solution: our range of ball and roller bearing pillow blocks. This honest, application-driven guidance helps our partners make the best technical and commercial decisions.

Conclusion

Choosing between adjustable and fixed pillow blocks hinges on managing shaft expansion; selecting the correct bearing insert (spherical roller for heavy loads) and proactively addressing common failure points like seals and corrosion are essential for long-term, cost-effective performance.

-

Explore the benefits of ball bearings for efficiency and precision in various industrial settings. ↩ ↩ ↩ ↩

-

Understanding the significance of low friction can enhance performance in high-speed machinery. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover where sliding bearings excel, especially in high load and low speed scenarios. ↩ ↩ ↩ ↩ ↩

-

Learn about specific applications that benefit from the unique properties of sliding bearings. ↩ ↩ ↩

-

Understanding the physics of friction can help in selecting the right bearing for your needs. ↩ ↩ ↩

-

Explore how high load capacity bearings can improve performance in heavy-duty applications. ↩ ↩ ↩

-

Find out how self-lubricating bearings can reduce maintenance and improve reliability. ↩ ↩ ↩ ↩

-

Learn about the applications and benefits of heavy-duty spherical roller bearings in tough conditions. ↩ ↩ ↩ ↩