Water is a bearing’s enemy in two forms: as a destroyer of lubrication and as a catalyst for corrosion. In washdown areas or outdoors, standard pillow blocks fail quickly. Water washes away grease, rust seizes components, and bearing failure leads to unplanned downtime in critical food processing, pharmaceutical, or outdoor material handling operations.

Waterproof pillow block bearings for washdown and outdoor use feature multiple sealing barriers (like triple-lip seals or labyrinth seals), corrosion-resistant housings (stainless steel or coated cast iron), and waterproof greases. They are designed to withstand direct high-pressure spray, humidity, and temperature fluctuations while protecting the bearing insert from contamination.

A standard pillow block with basic seals will not survive in these conditions. The term "waterproof" in an industrial context refers to a specific level of protection, not absolute impermeability. Understanding what makes a bearing unit truly suitable for wet environments requires looking at its components, common failure modes, and even the language used to describe it globally. Let’s dive into the details.

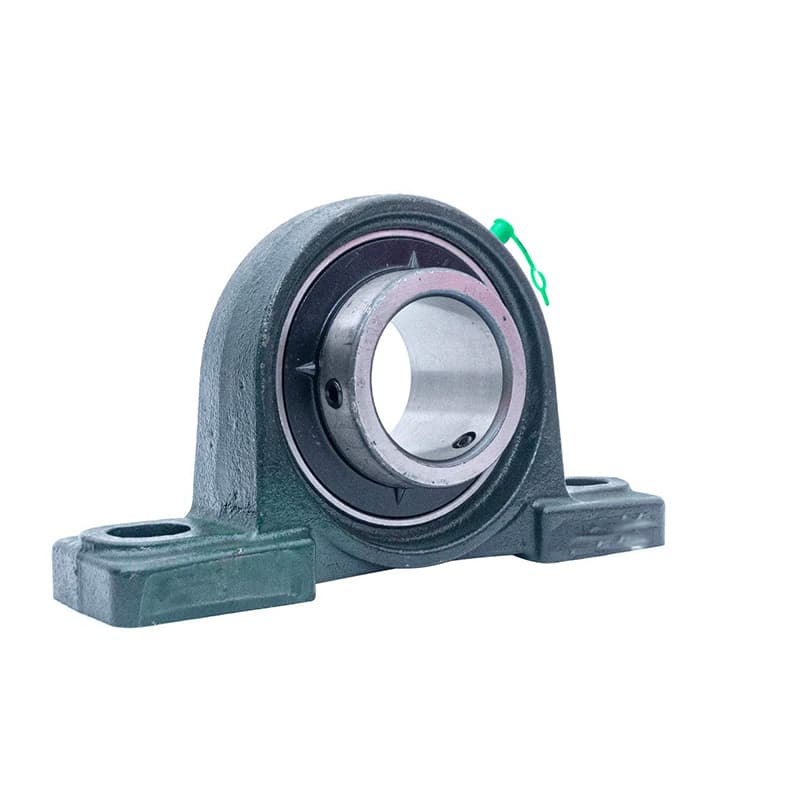

What is a pillow block bearing1 used for?

A loose bearing on a shaft is ineffective. It needs a stable base, protection, and a way to be mounted. The pillow block provides this complete package. It’s the interface between the rotating world of the shaft and the stationary world of the machine frame.

A pillow block bearing1 is a mounted unit used to support a rotating shaft. It consists of a bearing (like a ball or roller bearing) pre-assembled inside a sturdy housing with a base for bolting to a surface. Its primary use is to simplify installation, protect the bearing from the environment, and allow for easier maintenance in applications like conveyors, fans, agricultural equipment, and industrial machinery.

The Mounted Bearing System: More Than Just a Holder

The pillow block is a system that solves multiple practical problems at once. Its "use" extends beyond simple support; it integrates several critical functions into one ready-to-install component. For wet and harsh environments, each of these functions must be enhanced.

1. Simplified Installation and Alignment2:

Machinery builders don’t need to machine precise bearing seats in a large frame. They simply bolt the pillow block onto pre-drilled holes. Many blocks have self-aligning capabilities, which compensate for minor frame imperfections—a common issue in welded frames exposed to weather.

2. Integrated Environmental Protection3:

This is its most critical role in washdown and outdoor settings. The housing acts as a shield against direct spray and large debris. More importantly, it provides a structure to mount advanced sealing systems that a bare bearing cannot have.

3. Lubrication Management4:

Most pillow blocks are designed for re-lubrication. They have a grease fitting (zerk). This allows maintenance staff to purge old, contaminated grease (mixed with water or dirt) and inject fresh, clean grease without disassembly. This is vital for longevity in wet conditions.

4. Load Transfer and Support:

The housing, typically made of cast iron or pressed steel, distributes the bearing’s reaction forces over a larger area of the machine frame. This prevents stress concentrations.

In wet environments like a vegetable washing line or a outdoor stacker conveyor, the pillow block’s role is magnified. It’s not just a component; it’s the primary defense station for the bearing. For our clients building food processing equipment for export to Europe or North America, the pillow block specification is a key part of their machine’s hygiene and reliability certification. We work with them to supply blocks that meet these stringent demands. For distributors like Rajesh, understanding these uses helps him identify market opportunities beyond general industry, moving into the specialized and growing sectors of food, pharma, and outdoor logistics.

Are there waterproof bearings?

The term "waterproof" can be misleading. In engineering, we more accurately say "water-resistant1" or "sealed for washdown." No bearing is truly waterproof against indefinite immersion under pressure, but specially designed bearings and pillow blocks can provide a very high level of protection against spray, splash, and humidity.

Yes, there are bearings and pillow block units specifically engineered to be highly water-resistant1. They achieve this through multiple rubber contact seals2 (triple-lip), labyrinth seals, stainless steel components, and specialty greases. These are essential for applications in food processing (washdown), marine environments, outdoor machinery, and wastewater treatment where exposure to water is constant.

The Architecture of Water Resistance: A Multi-Layer Defense

Creating a bearing unit that can withstand water is about building layers of defense. Each layer addresses a different way water can cause failure. A single seal is rarely enough for high-pressure washdown; you need a system.

Layer 1: The Bearing Insert Itself

- Material: In corrosive environments, the bearing insert should be stainless steel (AISI 440C)3 or have a protective coating. This prevents rust from starting inside the unit.

- Grease: The bearing must be packed with a water-resistant, high-quality grease4r.com/products/bearings/ng-waterproof-bearings)1, high-quality grease. For food applications, this grease must also be NSF H1 registered. The grease acts as a hydrophobic barrier.

Layer 2: The Primary Dynamic Seal (The Critical Layer)

This is the seal at the shaft interface. Common types for waterproof applications include:

- Triple-Lip Contact Seals5: Three rubber lips in contact with the shaft. The outer lip deflects bulk water and debris. The middle and inner lips create sealed chambers filled with grease, providing multiple failure points before water reaches the bearing.

- Labyrinth Seals6: Non-contact seals with a complex, grooved path. When combined with a grease purge fitting, grease fills the labyrinth, creating an impassable viscous barrier for water. Excellent for heavy contamination but requires regular grease replenishment.

- V-Ring Seals: A rubber ring attached to the shaft that rotates with it, flinging water outward centrifugally. Often used as an additional, external seal.

Layer 3: The Housing and Static Seals

- Housing Material: The housing itself must resist corrosion. Stainless steel housings (304 or 316) are best for severe washdown. Coated cast iron (epoxy, nickel-plated) is a cost-effective alternative for less aggressive environments.

- Gaskets/O-Rings: Where the housing halves meet or where end caps attach, static rubber gaskets or O-rings prevent water from seeping through these joints.

Layer 4: The Purge and Relief System

A true washdown pillow block will have a grease fitting and a visible relief port7. During maintenance, new grease is pumped in. It flows through the bearing and seals, forcing out old grease along with any trapped water or contaminants through the relief port. This active cleaning is essential for long life.

Here’s how protection levels vary:

| Protection Level | Seal Type | Typical Use | Limitation |

|---|---|---|---|

| Basic Splash Resistance | Single or double lip seal. | Light outdoor exposure, occasional dampness. | Not for direct high-pressure spray. |

| High-Pressure Washdown | Triple-lip contact seals or labyrinth with grease purge. | Food, beverage, pharmaceutical processing. | Requires regular maintenance re-greasing. |

| Partial Immersion | Multiple seals, often with external V-ring, special housings. | Wastewater, marine (not deep submergence). | Not for continuous deep underwater use. |

At FYTZ, we manufacture pillow blocks for the middle to upper range of this spectrum. We produce units with triple-lip seals and nickel-plated cast iron housings8 that are perfect for most food plant washdowns. For more severe needs, we offer full stainless steel units. This range allows our distributors to serve a wide variety of wet-environment customers effectively.

What are the common problems with pillow blocks?

Failure in a wet environment rarely happens suddenly. It’s a process. Recognizing the early signs of these common problems allows for proactive maintenance and prevents catastrophic breakdowns during production.

The most common problems with pillow blocks in washdown/outdoor environments are seal failure leading to water and contaminant ingress1, corrosion of the housing and internal components2, lubrication washout or degradation3, and bearing failure due to the resulting contamination, rust, or lack of lubrication. Improper installation or misalignment also accelerates these issues.

A Failure Analysis: From Symptom to Root Cause

Understanding common problems is not just about listing issues; it’s about tracing the chain of causation. In wet environments, one problem typically leads to another in a predictable sequence. Let’s diagnose the most frequent failure pathways.

1. The Primary Killer: Seal Failure and Water Ingress

- Symptom: Grease leaking from the seal area appears milky or rusty (water-contaminated). Eventually, you may see rust stains.

- Root Causes:

- Seal Wear: The rubber lip wears against the shaft over time.

- Chemical Attack: Harsh sanitizers (chlorine, acids) degrade the rubber compound.

- Improper Installation: Damaging the seal during shaft insertion.

- Pressure Washer Damage: Direct high-pressure spray can force water past even good seals if aimed directly at the seal-shaft interface.

2. Corrosion: The Silent Destroyer

- Symptom: Red/brown rust on the housing, bolts, or visible on the shaft. In advanced stages, the bearing feels gritty or seizes.

- Root Causes:

- Incorrect Housing Material: Using standard cast iron in a wet environment.

- Damaged Coatings: Chips or scratches in plated housings expose bare metal.

- Galvanic Corrosion: Dissimilar metals (e.g., steel bolts in an aluminum housing) in the presence of water create a battery effect, accelerating corrosion.

3. Lubrication Failure

- Symptom: Bearing runs hot, makes noise, or seizes. The grease may be washed out entirely or turned into a hard, soapy substance.

- Root Causes:

- Washout: Water pressure displaces the grease.

- Emulsification: Water mixes with the grease, breaking down its structure and losing lubricity.

- Use of Standard Grease: Non-water-resistant grease fails quickly.

4. Bearing Insert Failure

This is usually the result of the above problems. Contamination and lack of lubrication cause:

- Abrasive Wear: Grit and rust particles grind down raceways and rolling elements.

- Fatigue (Spalling): Contaminants create stress points, leading to surface pitting.

- Corrosion Pitting: Rust on raceways creates indentations that cause vibration and noise.

Preventive Strategies vs. Common Problems:

| Problem | Preventive Strategy | FYTZ Solution Example |

|---|---|---|

| Seal Failure | Use multi-lip seals4; avoid direct high-pressure spray on seals. | Supply blocks with triple-lip nitrile rubber seals resistant to common sanitizers. |

| Corrosion | Use corrosion-resistant housing material5. | Offer nickel-plated cast iron and full AISI 304 stainless steel housings. |

| Lubrication Washout | Use water-resistant grease and re-lubricate frequently to purge water. | Pre-grease with high-quality, water-resistant lithium complex or polyurea grease6. |

| Misalignment Stress | Use self-aligning bearing inserts. | Supply blocks with spherical roller bearing inserts that tolerate misalignment. |

For a maintenance manager in a brewery, this knowledge is actionable. They know to inspect seals regularly, re-grease on schedule (using the purge method), and specify nickel-plated or stainless housings for replacements. For Rajesh, when a customer complains of frequent failures, he can diagnose the likely cause (e.g., "Are they pressure washing it directly?") and recommend an upgrade to a more suitable FYTZ waterproof block, solving the recurring issue.

What is another name for a pillow block1 bearing?

Terminology confusion causes delays and ordering mistakes. A maintenance technician might ask for a "plummer block2," while the parts system lists "pillow block1s." This simple difference can halt a repair until the correct term is clarified, wasting valuable time.

Another very common name for a pillow block1 bearing is a "plummer block2." This term is especially prevalent in British-influenced engineering circles (UK, India, Australia, South Africa). Other names include mounted bearing unit3, bearing housing4, or bearing block. These all refer to the same concept: a pre-assembled bearing and housing system ready for installation.

Global Terminology: Speaking the Same Language in International Trade

The variety of names reflects regional engineering traditions and the broad applicability of the product. For international buyers, distributors, and engineers, understanding these terms is crucial for clear communication in a global supply chain.

1. Pillow Block vs. Plummer Block: The Regional Divide

- Pillow Block: This is the dominant term in North America and is widely used in international trade catalogs. It evokes the image of a block that sits like a pillow under the shaft.

- Plummer Block: This is the traditional term in the United Kingdom and Commonwealth countries. It is equally correct and refers to the same product. When our sales team communicates with Rajesh in India, we use "plummer block2" because that’s the term his local market understands.

2. Technical and Catalog Names:

Beyond these, you will encounter more precise terms that define the style or standard:

- Mounted Bearing Unit or Bearing Housing Unit: These are generic, umbrella terms that include not just pillow block1s, but also flange blocks, take-up units, and cartridge units.

- "UCP" Series: This is a very common industry standard product code. "UCP" typically denotes a Pillow Block with a Pillow base, using a set screw locking mechanism. For example, a UCP 205 is a specific pillow block1 for a 25mm shaft.

- "SN" Series: This refers to standardized housing dimensions (e.g., SN 506, SN 607). It specifies the housing size that will accept a bearing of a certain outer diameter, regardless of the manufacturer.

This table helps translate between naming conventions:

| Term Used By Customer | What They Usually Mean | Key Identifier |

|---|---|---|

| "I need a pillow block1 for a 1-inch shaft." (USA) | A block with a base, for a 1" (25.4mm) shaft. | Base with bolt holes. |

| "We use plummer block2s on our conveyor." (India/UK) | The same as above. | Same product. |

| "Part number is UCFL 208." | A Flange Block (FL) for a 40mm shaft (208), with set screw lock. | Mounting flange instead of a base. |

| "The housing is an SN 506." | A housing for a bearing with 130mm outer diameter. | Dimension-based specification. |

In our daily operations at FYTZ, we encounter all these terms. A request from a machinery builder in Turkey might come in for "SN 506 housings." An email from a South African miner might ask for "heavy-duty plummer block2s." Our technical team is fluent in this language. We confirm the bore size, the locking method, and the seal type to ensure we supply exactly what is needed. This clarity eliminates errors in the global order process. For a distributor, using the correct local term builds trust and makes their catalog and communications clear to their end-customers.

Conclusion

Selecting a waterproof pillow block for washdown or outdoor use requires specifying a system with multi-layer sealing, corrosion-resistant materials, and water-proof grease, while understanding regional terminology like "plummer block" ensures accurate global sourcing.

-

Explore the concept of pillow block bearings and their applications in various industries. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore this link to understand the significance of the term ‘plummer block’ in engineering and its regional usage. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about mounted bearing units and their applications in various engineering contexts. ↩ ↩ ↩ ↩

-

Discover the role of bearing housings in machinery and how they contribute to performance. ↩ ↩ ↩ ↩

-

Exploring material options can lead to better choices for durability in wet environments. ↩ ↩

-

Understanding grease types can improve lubrication strategies and equipment reliability. ↩ ↩

-

Understand the critical role of grease fittings and relief ports in maintaining the longevity of pillow blocks. ↩

-

Discover the benefits of using nickel-plated cast iron housings in bearings for enhanced corrosion resistance. ↩