In textile production, vibration is the enemy. It causes yarn breaks, fabric defects, and excessive machine wear. A noisy, vibrating bearing is not just an annoyance; it’s a signal of imminent failure that can stop a production line costing thousands per hour in lost output.

Deep groove ball bearings are essential for textile machinery due to their low friction, high-speed capability, low noise, and ability to handle both radial and axial loads. Selecting high-precision grades (P5/P6) and proper seals significantly reduces vibration and unplanned downtime, ensuring smooth, efficient fabric and yarn production.

The choice of bearing in a textile machine is a direct investment in product quality and operational uptime. A standard industrial bearing is not good enough. To make the right selection, you need to understand what makes a deep groove ball bearing unique, its specific advantages for high-speed applications, and how it differs from other common bearing types. Let’s explore the fundamentals.

What is a deep groove ball bearing1?

Many people refer to any small bearing as a "ball bearing," but there are important differences. Using the wrong type, like an angular contact bearing in a simple support role, adds unnecessary cost and complexity. The deep groove design is the versatile workhorse for a reason.

A deep groove ball bearing1 is the most common type of rolling bearing. It consists of an inner ring, an outer ring, a set of steel balls, and a cage to separate the balls. Its defining feature is deep, uninterrupted raceway grooves on both rings, which allows it to support significant radial loads2 and moderate axial (thrust) loads from both directions simultaneously.

The Anatomy of Versatility: Design and Function

The name "deep groove" is the key to understanding its capabilities. The deep, continuous grooves machined into the rings are not just for holding balls; they define the bearing’s load-handling characteristics.

Key Design Elements:

- Deep, Continuous Raceways: The grooves are deep and run around the entire circumference of both rings without interruption. This geometry allows the balls to be securely guided even when the bearing is subjected to axial loads. The deep groove cradles the ball, enabling it to carry thrust from either side.

- Point Contact: The balls make point contact with the raceways. This results in very low rolling friction3, which is the foundation for high-speed operation and energy efficiency.

- Conformity: The radius of the raceway groove is slightly larger than the ball radius. This provides a good contact area to distribute load while still allowing smooth rolling.

Primary Functions in a Machine:

- Support Rotating Shafts: Their main job is to allow a shaft to rotate freely with minimal resistance against a stationary housing.

- Carry Combined Loads: They can handle radial load (like the weight of a roller) and axial load (like thrust from a drive belt or slight misalignment) without needing additional bearing arrangements.

- Provide Precise Guidance: High-precision versions offer accurate shaft positioning with minimal runout.

In textile machinery4, this versatility is crucial. A spinning spindle, for example, experiences primarily radial load from the rotating mass. But there can also be small axial forces from yarn tension or drive mechanisms. A deep groove ball bearing1 handles both simply and efficiently. Its low friction is perfect for the high speeds (often 10,000 RPM or more) required in modern textile production. At FYTZ, we produce millions of these bearings because they are the backbone of light-to-medium duty industrial motion, including the vast textile industry in countries like India, Bangladesh, and Turkey where our distributors operate.

What are the advantages of deep groove ball bearings1?

Choosing a bearing based only on load rating or price misses the bigger picture. The inherent advantages of deep groove ball bearings1 make them the default choice for a huge range of applications, especially where performance, cost, and simplicity must be balanced.

The key advantages of deep groove ball bearings1 are versatility in handling both radial and axial loads, low friction enabling high-speed operation2, simple design for easy installation3 and low cost, availability in high precision grades for smooth running4, and low noise generation5, making them ideal for applications from electric motors to precision machinery like textile spindles.

Breaking Down the Value Proposition for Textile Applications

Each advantage directly addresses a critical need in textile manufacturing. Let’s examine how these general benefits translate into specific performance on the factory floor.

1. Combined Load Capacity (Versatility):

- Textile Benefit: Simplifies machine design. A single deep groove bearing can often replace a more complex pair of bearings (like two angular contact bearings) on a shaft that sees light to moderate combined loads. This reduces parts count, cost, and assembly time.

2. Low Friction and High-Speed Capability:

- Textile Benefit: This is paramount. Spinning, winding, and weaving processes demand very high rotational speeds. The low friction of point contact means less heat generation and lower energy consumption. It allows the bearing to reach and sustain the high RPMs needed for productivity without overheating.

3. Low Noise and Vibration (With Precision Grades):

- Textile Benefit: Directly impacts product quality. Vibration from a bearing transmits to the yarn or fabric, causing imperfections. Deep groove ball bearings, especially those manufactured to precision classes P5, P6, or ABEC 5/7, have extremely tight tolerances on dimensions and running accuracy (runout). This results in exceptionally smooth, quiet rotation. For a textile OEM, specifying P5 bearings is a direct investment in a quieter, higher-quality machine.

4. Simple Design and Cost-Effectiveness:

- Textile Benefit: They are relatively simple to manufacture at scale, leading to a favorable cost. For machinery builders producing hundreds or thousands of units, this keeps the overall machine cost competitive. They are also easy for maintenance staff to handle and replace.

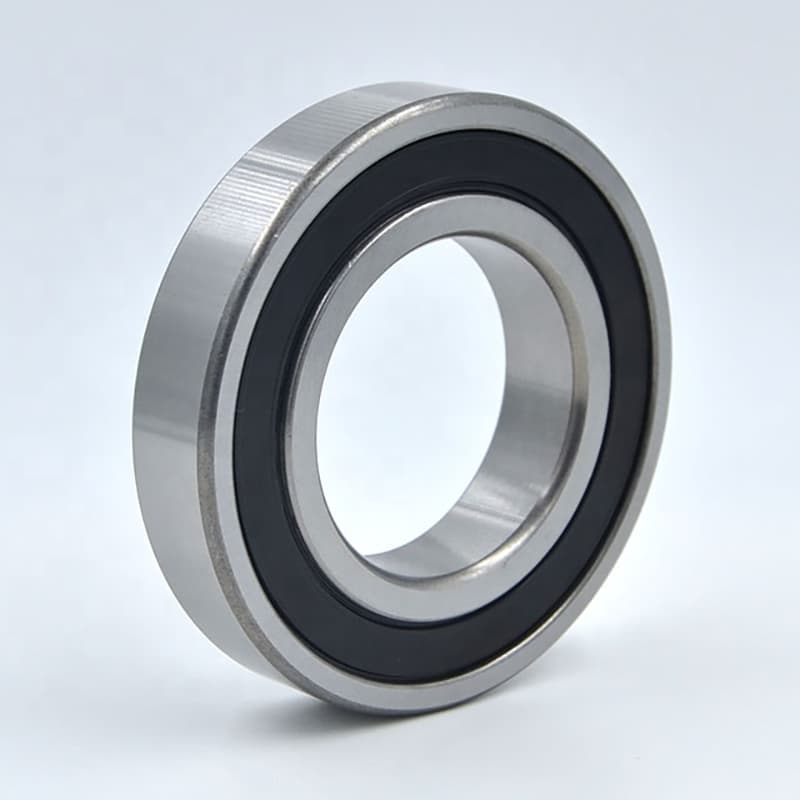

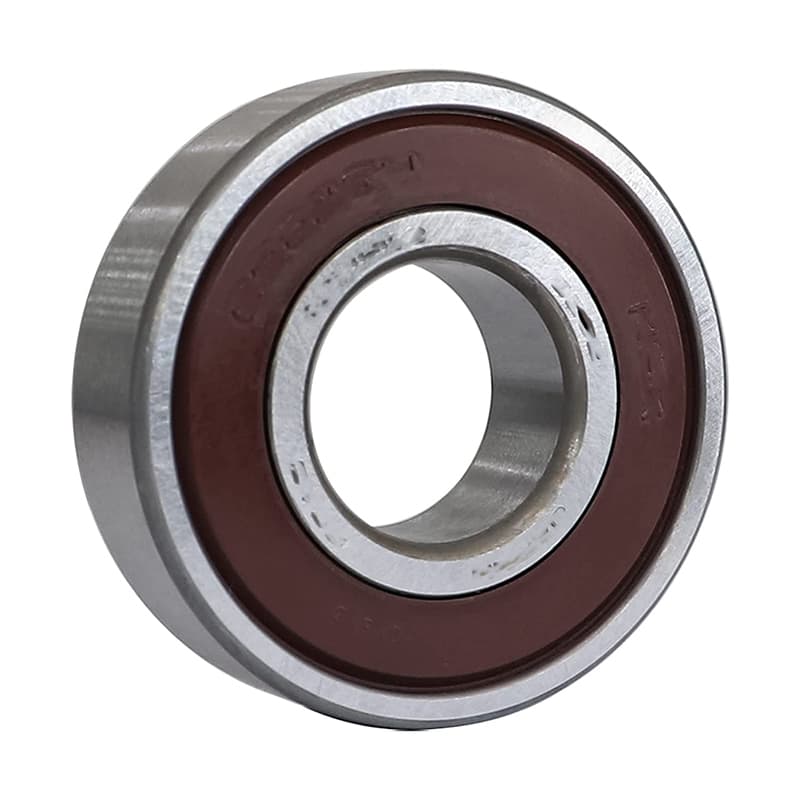

5. Availability of Sealed and Shielded Versions:

- Textile Benefit: Textile mills are full of lint and fine fibers. Bearings can be supplied with shields (ZZ) or contact seals (2RS) to prevent this contamination from entering the bearing, which would cause abrasive wear and rapid failure. Sealed-for-life versions also reduce maintenance needs.

Advantage Comparison for Textile Use:

| Advantage | Impact on Textile Machinery | Result |

|---|---|---|

| High-Speed, Low Friction | Enables fast spindle and roller speeds. | Higher production throughput, lower energy costs. |

| Low Noise/Vibration (P5/P6) | Minimizes transmission of vibration to yarn/fabric. | Improved product quality, fewer breaks, less machine wear. |

| Sealed Versions (2RS) | Protects against lint and fiber intrusion. | Longer bearing life, reduced contamination-related downtime. |

| Cost-Effectiveness | Lowers component cost for machine builders. | More competitive machine pricing. |

At FYTZ, we leverage these advantages for our clients. When a textile machinery manufacturer in Vietnam partners with us, we don’t just supply a standard bearing. We discuss their speed requirements and recommend bearings from our P5/P6 precision line6. We ask about the environment and suggest 2RS rubber-sealed versions to keep out lint. This application-specific approach ensures our bearings deliver their full potential in reducing downtime and vibration for our partners’ customers.

What is a deep groove?

The term "deep groove" is not just descriptive; it’s a specific engineering feature with a measurable purpose. A shallow groove would not allow the bearing to function as intended, particularly under axial load. Understanding this geometry explains why this bearing type is so capable.

In the context of bearings, a deep groove refers to the relatively deep, continuous, circular raceway machined into both the inner and outer rings of a deep groove ball bearing1. The depth and curvature of this groove are precisely controlled to securely guide the balls, allow for a sufficient contact area to carry load, and enable the bearing to support axial loads2 from both directions by preventing the balls from slipping out of the raceway under thrust.

The Geometry That Defines Performance

The groove’s design is a balance of several factors. It’s not arbitrarily deep; its dimensions are calculated based on ball size and desired performance characteristics. This geometry is what separates deep groove ball bearing1s from other types like angular contact or self-aligning ball bearings.

Key Aspects of the Deep Groove:

-

Depth and Conformity:

- The groove is deep enough so that the ball is nestled securely. The radius of the groove (raceway curvature3) is slightly larger than the ball’s radius. This ratio, often called the conformity4, is typically around 0.52 to 0.54. This means the groove is about 52-54% as curved as the ball itself.

- Why it matters: This slight difference creates an elliptical contact area (not a single point) between the ball and the raceway. This spreads the load over a small area, reducing contact stress and increasing load capacity compared to a theoretical single point, while still maintaining low friction.

-

Continuity:

- The groove is a continuous, unbroken circle. There are no shoulders or lips that stop the balls from moving along the groove.

- Why it matters: This continuity is what allows the bearing to handle axial loads2 from both directions. When an axial force is applied, the balls can roll along the groove to the opposite side, transmitting the thrust load. In a bearing with a shallower or shouldered groove (like some specialized types), axial load in one direction would force the balls against a shoulder, causing high stress and preventing rolling.

-

Shoulder Height:

- The sides of the groove rise to form shoulders. These shoulders help retain the balls and cage assembly, especially when the bearing is handled unmounted.

- Why it matters: Provides structural integrity and ease of handling.

Comparison with Other Groove Types:

| Bearing Type | Raceway Groove Characteristic | Axial Load Capacity |

|---|---|---|

| Deep Groove Ball Bearing | Deep, continuous, symmetrical. | Good, both directions. |

| Angular Contact Ball Bearing | Asymmetric, with one shoulder higher than the other. | Very high, one direction only (designed for thrust). |

| Self-Aligning Ball Bearing | Spherical groove on outer ring. | Limited. Primary feature is self-alignment. |

For a textile machine designer5, this deep, continuous groove is perfect. It means they can use one bearing type on a shaft that might see slight axial forces from belt drives or thermal expansion, without worrying about direction. The simplicity is elegant. In our manufacturing at FYTZ, grinding this groove to precise dimensions and smoothness is a critical step. The finish of the groove directly affects friction, noise, and fatigue life—all critical for the high-speed, quiet operation required in textile mills.

What is the difference between deep groove and normal bearings?

The term "normal bearing" is ambiguous and misleading. In technical terms, there is no "normal" bearing. People often use it to refer to the most common type, which is the deep groove ball bearing1, or to a standard-grade version versus a precision grade. Clarifying this language prevents specification errors.

There is no separate category called "normal bearings." The deep groove ball bearing1 is the standard, normal, and most common bearing type. However, a key difference exists within this category: between standard precision2 (Normal/ABEC 1 or P0) deep groove bearings and high-precision3 (e.g., ABEC 5/P5, ABEC 7/P4) deep groove bearings. The "normal" conversational reference often means the standard precision2 version, which has wider tolerances4 and may generate more vibration5 than a high-precision3 grade.

Precision Class: The Real Differentiator Within a Family

When someone asks about "normal" bearings, they are usually trying to understand why one deep groove ball bearing1 might cost significantly more than another of the same size. The answer almost always lies in the precision class6 and sometimes in special features like seals or materials.

Understanding Precision Classes (Tolerances):

All manufactured parts have tolerances4—allowed variations from perfect dimensions. Bearings are classified by how tight these tolerances4 are.

-

Standard/Commercial/Normal Grade (Often P0 or ABEC 1):

- This is the most common and cost-effective grade.

- It has the widest allowable tolerances4 for bore diameter, outer diameter, width, and radial runout (how much the inner ring "wobbles" relative to the outer ring).

- Use: Perfectly adequate for many general industrial applications like simple pulleys, idlers, or low-speed fans where smoothness is not critical.

-

High-Precision Grades (P5, P6, P4 / ABEC 5, 7, 9):

- These grades have much tighter tolerances4. For example, the allowed runout in a P5 bearing might be less than half that of a P0 bearing.

- Use: Essential for applications requiring smooth, quiet, and accurate rotation. This includes machine tool spindles, high-speed electric motors, medical devices, and textile machinery.

Why This Matters for Textile Machinery:

Vibration in a bearing comes from imperfections. A bearing with higher runout (wobble) acts like a tiny unbalanced wheel, creating vibration5 at the frequency of its rotation. In a textile spindle running at 15,000 RPM, this vibration5 is catastrophic.

- A P0 (normal) bearing will likely cause unacceptable vibration5, leading to yarn breaks, fabric defects, and noisy operation.

- A P5 or P6 precision bearing will run smoothly and quietly, directly contributing to product quality and reduced downtime.

Other Possible "Differences" People Might Mean:

- Sealed vs. Open: A "normal" bearing might be open (no seals), while a specific application might require a 2RS sealed bearing.

- Material: A "normal" bearing is chrome steel (52100). Special applications might use stainless steel7 (440C) or ceramic.

Decision Guide for Textile Applications:

| If Your Textile Machine Component… | Choose a Deep Groove Ball Bearing with… | Reason |

|---|---|---|

| Is a high-speed spindle or winder | P5 or P6 Precision Class, open or lightly sealed. | Minimizes vibration5 for quality and allows for oil lubrication if needed. |

| Is a general support roller in a dusty mill | Standard P0 Precision, with 2RS rubber seals. | Cost-effective, protected from lint. Vibration less critical. |

| Operates in a wet process (dyeing, finishing) | Stainless Steel material, with appropriate seals. | Corrosion resistance is the priority. |

At FYTZ, we produce both standard and precision deep groove ball bearing1s. For our textile machinery OEM clients, we primarily supply from our P5 and P6 precision lines. We explain that this is not an unnecessary cost but a core performance requirement for their machines. For distributors like Rajesh, when a textile mill customer complains about vibration5 or frequent bearing failure on a critical spindle, the solution is often not just a replacement bearing, but an upgrade to a P5 precision bearing from our stock. This knowledge allows him to provide true value and solve his customer’s root problem.

Conclusion

For textile machinery, deep groove ball bearings reduce downtime and vibration when selected as high-precision grades (P5/P6) with appropriate sealing, leveraging their inherent advantages of low friction, high-speed capability, and combined load handling for smooth, reliable operation.

-

Explore the benefits of deep groove ball bearings, including their versatility and common applications in various industries. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about standard precision in bearings and how it affects performance and application suitability. ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the applications and benefits of high-precision bearings in industries requiring accuracy and smooth operation. ↩ ↩ ↩ ↩ ↩

-

Gain insights into tolerances in bearing manufacturing and how they influence the quality and functionality of bearings. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore the relationship between vibration and bearing performance, and learn how to minimize it for better efficiency. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Understand the significance of precision class in bearings and its impact on performance and longevity. ↩ ↩

-

Learn about the advantages of stainless steel bearings, especially in corrosive environments and demanding applications. ↩