Speed can be a bearing’s worst enemy. At high RPM, centrifugal forces try to tear the bearing apart. Friction generates intense heat. Using a bearing not designed for speed leads to rapid overheating, lubrication failure, and a catastrophic seizure that can destroy an entire machine spindle.

High-speed deep groove ball bearings are needed when rotational speed is the primary design challenge, not load. They are essential for electric motors, machine tool spindles, turbochargers, and precision instruments where low friction, minimal heat generation, and smooth operation at high RPM are critical for performance and reliability.

The term "high-speed" is often used loosely. Not every application calling for a deep groove ball bearing truly needs a high-speed variant. Misapplication wastes money or causes failure. Understanding the real triggers for a high-speed design is key to optimal machine performance and cost control. Let’s define those triggers clearly.

What are the applications of deep groove ball bearings1?

People often think ball bearings are simple and generic. But their versatility is their strength. They are the default choice for a massive range of everyday machinery because they offer a perfect balance of capability, cost, and ease of use.

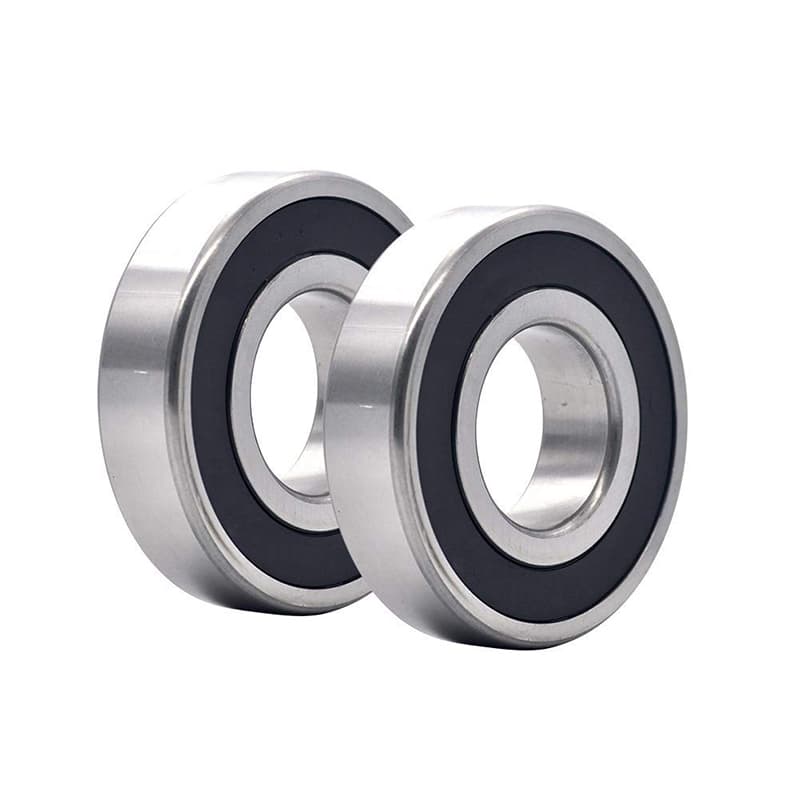

Deep groove ball bearings are used in countless applications where moderate radial and axial loads meet medium to high speeds. Their most common uses are in electric motors (from small appliances to industrial motors), automotive components (wheels, alternators), gearboxes, household appliances, pumps, fans, and general machinery where reliable, low-friction rotation is required.

The Workhorse of Industry: Where Simplicity Meets Performance

The applications for deep groove ball bearings1 are vast because they solve the most common set of problems in machine design. To understand "where" they are used, we need to look at "why" they are used. Their design offers three fundamental advantages that fit a wide spectrum of needs.

First, they are mechanically simple and cost-effective to manufacture2. Their symmetrical, deep raceway grooves allow them to handle radial loads and axial loads in both directions. This makes them a versatile, one-size-fits-many solution. A designer doesn’t need to worry about load direction in a simple shaft; a deep groove ball bearing will likely handle it.

Second, they have very low starting and running torque3. The point contact between balls and raceways creates minimal friction. This makes them highly efficient, which is crucial for electric motors where energy loss means heat and wasted power.

Third, they can achieve high rotational speeds4. With proper design (cage, lubrication, precision), they can operate at much higher RPMs than roller bearings of similar size.

We can categorize their applications by the primary demand they satisfy:

| Primary Application Demand | Typical Examples | Why Deep Groove Ball Bearings Are Used |

|---|---|---|

| High-Speed, Low/Moderate Load | Electric motor shafts (induction, servo), spindle shafts, turbochargers, dental handpieces. | Lowest friction, can be made to high precision (P5, P4) for smooth, quiet, high-RPM operation. |

| General Purpose, Cost-Sensitive | Household fans, washing machines, conveyor idlers, skateboards, office machinery. | Inexpensive, reliable, and sufficient for the loads and speeds involved. |

| Combined Radial & Axial Load | Automotive wheel hubs (supporting car weight and cornering forces), small gearboxes. | Ability to handle thrust from both directions without complex bearing arrangements. |

| Precision & Low Noise | Medical devices, computer cooling fans, precision instruments. | Can be manufactured to ABEC 5/7/9 (P5/P4/P2) tolerances for ultra-smooth, quiet running. |

For a bearing importer like Rajesh in India, this breadth is his business. He supplies deep groove ball bearings1 to car parts wholesalers for alternators and to industrial repair shops for motor rebuilds. At our FYTZ factory, we produce them in vast quantities because they are the backbone of industrial and consumer machinery worldwide. When a client from Vietnam needs bearings for a new line of electric fans, we don’t just sell a bearing; we ensure the cage material (often a polymer for quiet operation) and the grease are suited for continuous, low-torque rotation. This application knowledge is part of our standard service.

Which type of bearing is best for high speeds?

At extreme speeds, the physics change. The cage holding the balls becomes critical. The lubrication method shifts from grease to oil. The bearing’s internal geometry is optimized not for load, but for minimizing centrifugal force and friction heat. A bearing chosen for load capacity will fail here.

For the highest rotational speeds, angular contact ball bearings1 are generally considered the best. They are designed to handle primarily axial loads at high speed, and can be preloaded for extreme rigidity. For high-speed applications with combined loads, precision deep groove ball bearings2 and cylindrical roller bearings3 are also excellent choices, depending on the specific load profile.

The High-Speed Hierarchy: Matching Bearing Physics to Application Needs

Declaring one bearing "best" for high speed is too simplistic. The best choice depends on the type of high-speed application: is it a machine tool spindle (very high speed with axial load), an electric motor (high speed with light load), or a turbocharger (extreme speed with high temperature)? Each scenario favors a different bearing design.

Let’s analyze the contenders based on the key challenges of high speed: managing centrifugal forces4, minimizing friction heat5, and maintaining stability.

1. Angular Contact Ball Bearings (e.g., 70xx series):

- Why They Excel: They are the champion for very high-speed spindles. Their key feature is the contact angle. The balls contact the raceways at an angle, optimized to handle high axial (thrust) loads generated by cutting tools or grinding wheels at speed. They are almost always used in pairs, preloaded against each other. This preload eliminates all internal clearance, providing exceptional rigidity and rotational accuracy, which is vital for precision machining.

- Limitation: They are primarily for axial or combined loads. Pure high-speed radial load applications might use a different type.

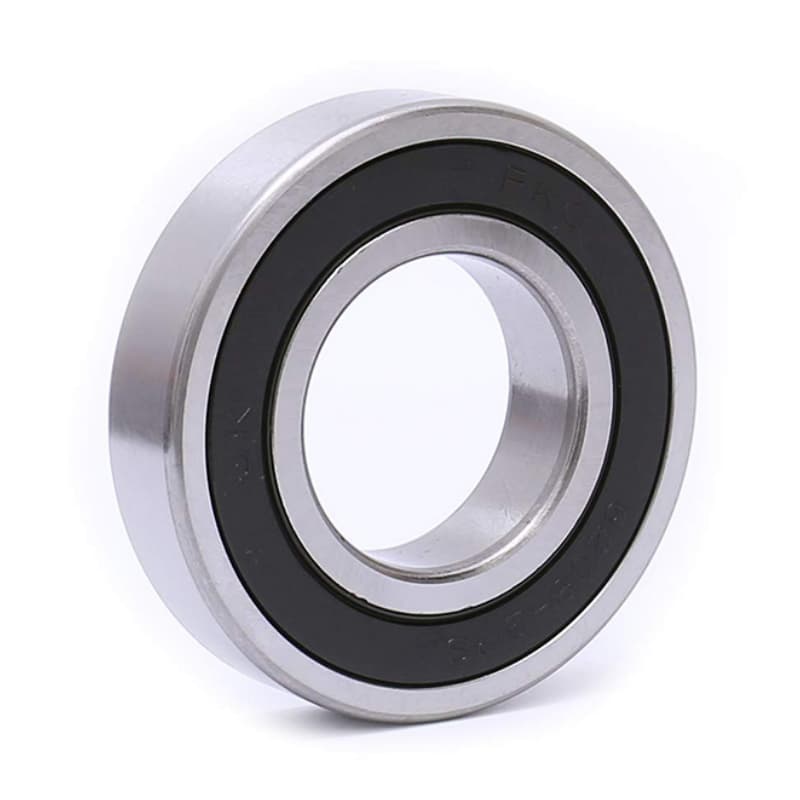

2. Precision Deep Groove Ball Bearings (ABEC 5/P5 and above):

- Why They Excel: They are the best all-rounder for high-speed, low-to-moderate load applications. Their symmetrical design handles radial and bilateral axial loads. When manufactured to high precision grades (P5, P4), they have extremely tight tolerances and smooth raceways. This minimizes vibration and heat generation. They are the standard for electric motors, high-speed spindles in routers, and pumps.

- Key for Speed: They often use lightweight polyamide (plastic) cages or specially designed brass cages to reduce centrifugal force on the balls.

3. Cylindrical Roller Bearings (e.g., NJ type with cage):

- Why They Excel: They are the best for very high-speed applications with pure radial loads. Their line contact provides high radial capacity, and a well-designed cage allows rollers to operate at high speeds with low friction. They are common in aircraft jet engines, high-speed machine tool main shafts, and high-performance gearboxes.

- Limitation: They cannot handle axial loads (unless flanged).

This comparison table clarifies the selection:

| Bearing Type | Best For High-Speed Applications Where… | Not Ideal For… |

|---|---|---|

| Angular Contact Ball Bearing | Extreme rigidity & precision are needed (machine tools). Axial load is primary. High speeds with precise preload. | Simple, cost-sensitive radial load applications. |

| Precision Deep Groove Ball Bearing | A balance of radial/axial load, high speed, and cost is needed (electric motors, fans). | Extreme axial loads or the highest possible rigidity. |

| Cylindrical Roller Bearing | The load is purely radial and very high speed is critical (jet engine main shaft). | Any axial load or applications with misalignment. |

For our clients who are electric motor manufacturers in Brazil or Turkey, the precision deep groove ball bearing is their core component. We work with them on OEM specifications6—providing bearings with the exact clearance (C3 for motor applications is common), cage material (PP or PEEK polymer for low noise and weight), and grease (specific dielectric and temperature properties). We confirm their required "dn value7" (bore x speed) to ensure our bearing’s cage and lubrication are up to the task. This technical partnership prevents field failures.

What are the disadvantages of deep groove ball bearings?

Choosing a deep groove ball bearing for the wrong job highlights its weaknesses. In a heavy shock load application, the small point contact1 can dent the raceways. In a severely misaligned setup, the balls skid and scrape instead of rolling smoothly. Knowing the limits prevents misapplication.

The main disadvantages of deep groove ball bearings are their limited load capacity2 compared to roller bearings (due to point contact1), sensitivity to misalignment3 which causes noise and premature wear, and lower stiffness which can allow more shaft deflection under load. They are also generally not suitable for very high temperatures4 or extreme contamination without special seals5.

Understanding the Trade-Offs: When to Look Beyond the Default Choice

The deep groove ball bearing’s advantages of simplicity, speed, and cost come with inherent trade-offs. A good engineer or procurement manager must recognize these limitations to know when a different bearing type is necessary. Let’s examine each key disadvantage in the context of real applications.

1. Lower Load Capacity (Point Contact vs. Line Contact):

This is the most significant limitation. The balls make point contact1 with the raceways. This concentrates stress on a very small area. In contrast, a cylindrical or spherical roller bearing has line contact, spreading the load over a longer area. Therefore, for the same physical size, a roller bearing has a much higher dynamic (C) and static (C0) load rating.

- Consequence: Using a deep groove ball bearing in a heavy-duty conveyor head pulley or a crusher bearing position will lead to rapid fatigue failure (spalling). The bearing size needed to handle the load might be impractically large.

2. Sensitivity to Misalignment:

Deep groove ball bearings are designed for precise alignment between the shaft and housing. They have very little internal ability to accommodate angular misalignment (typically less than 0.1 degrees). If the shaft deflects under load or the housing is poorly machined, the balls are forced to run on the edge of the raceway groove.

- Consequence: This causes increased friction, heat, noise (a high-pitched whine), and accelerated wear. In agricultural machinery or construction equipment where frames flex, a spherical roller bearing is a far better choice.

3. Lower Radial Stiffness:

Due to the point contact1 and internal clearances, they are less rigid than preloaded tapered roller bearings or angular contact bearings. Under load, the shaft can move slightly within the bearing (radial play).

- Consequence: In machine tool spindles or precision gearboxes where shaft position must be exact under cutting forces, this lack of rigidity is unacceptable. A preloaded bearing pair is used instead.

4. Limitations in Harsh Environments:

While sealed versions exist, the standard deep groove ball bearing design is not inherently robust against contamination or high temperatures4. The seals needed for full protection add friction, impacting the high-speed advantage.

- Consequence: In a dusty sawmill or a hot kiln, a standard deep groove ball bearing will have a very short life unless it is part of a specially designed, fully protected housing unit.

Here is a decision guide for when to consider an alternative:

| If Your Application Has… | Consider This Alternative Bearing | Reason |

|---|---|---|

| Very High Radial Loads | Cylindrical Roller Bearing | Higher load capacity via line contact. |

| High Load with Misalignment | Spherical Roller Bearing | Self-alignment protects against misalignment stress. |

| High Combined Load & Need for Rigidity | Tapered Roller Bearing (paired) | Handles heavy radial and axial load, can be preloaded for stiffness. |

| Extreme Contamination | Specialty Sealed Cartridge or Spherical Roller Pillow Block | Built-in, heavy-duty sealing and more robust design. |

At FYTZ, we produce all these bearing types6. When a client like a gearbox manufacturer in Indonesia consults us, we ask about their load, speed, and alignment conditions. If their design has heavy gears and potential housing warpage, we might suggest a spherical roller bearing instead of the deep groove ball bearing they initially considered. This honest guidance prevents future problems and builds long-term partnerships with our distributors and OEM clients.

What rpm is considered high speed for a bearing?

A number like "10,000 RPM" sounds fast, but for a small bearing in a dental drill, it’s normal. For a large bearing in a wind turbine, 200 RPM is high speed due to the immense forces involved. The question needs context; speed is relative to size.

There is no single RPM value that defines "high speed" for all bearings. It is defined by the dn value1 (bore diameter in mm multiplied by speed in RPM). Generally, dn value1s above 500,000 mm/min are considered high speed. For example, a 50mm bore bearing at 10,000 RPM (dn = 500,000) is operating at a high speed.

The dn Value: The True Measure of Bearing Speed

The concept of "high speed" is meaningless without considering the bearing’s size. The centrifugal force on a rolling element is the real enemy at high speed. This force is proportional to the mass of the element and the square of its rotational speed. Larger bearings have heavier balls or rollers, so they experience much higher centrifugal forces at the same RPM as a smaller bearing. The dn value1 (bore (d) in mm x speed (n) in RPM) is the industry’s standard metric to normalize this.

How to Use the dn Value:

- Calculate: dn = d (mm) × n (RPM). Example: A 25mm bore bearing at 20,000 RPM has a dn of 500,000.

- Classify:

- Low Speed: dn < 100,000 mm/min

- Medium Speed: 100,000 ≤ dn < 500,000 mm/min

- High Speed: 500,000 ≤ dn < 1,000,000 mm/min

- Very High Speed: dn ≥ 1,000,000 mm/min

However, the dn value1 is a starting point. The real limiting factors at high dn value1s are:

- Cage Design and Material2: At high speeds, the cage experiences tremendous stress. Pressed steel cages can fail. Machined brass cages or lightweight polymer cages (PEEK, PA66) are used for high-speed bearings. Their design is crucial for guiding the balls smoothly.

- Lubrication Method3: Grease has a maximum usable dn value1 (often around 500,000 for standard greases). Beyond this, grease cannot be retained and churns, generating heat. Oil lubrication (oil-air mist, oil jet, or oil bath) is required for very high speeds. It provides better cooling and lower churning loss.

- Internal Geometry and Precision4: High-speed bearings have optimized internal geometries. This includes smaller ball sizes (to reduce centrifugal force) and special raceway curvature (oscillation) to control ball skidding. High precision grades (P5, P4) ensure minimal vibration.

Let’s look at real-world examples across different sizes:

| Application Example | Approx. Bearing Bore (d) | Operating Speed (n) | dn Value | Classification & Key Features |

|---|---|---|---|---|

| Electric Hand Grinder | 8 mm | 25,000 RPM | 200,000 | Medium Speed. Polymer cage, grease lubricated. |

| Industrial Electric Motor (75kW) | 50 mm | 3,000 RPM | 150,000 | Medium Speed. Common industrial bearing. |

| Machine Tool Spindle | 70 mm | 15,000 RPM | 1,050,000 | Very High Speed. Angular contact pairs, oil-jet lubrication, P4 precision. |

| Turbocharger | 10 mm | 150,000 RPM | 1,500,000 | Extreme Speed. Specialized floating bearings, oil-cooled. |

For our clients, this understanding is practical. When a pump manufacturer in Egypt asks for a bearing for a new high-speed model, we don’t just ask for the RPM. We ask for the shaft diameter and the RPM to calculate the dn. If it’s above 400,000, we know to recommend a bearing with a machined brass cage (like our FYTZ "J" suffix series) and discuss lubrication options. This proactive technical discussion prevents them from selecting a standard bearing that would overheat and fail. For distributors, this knowledge helps them qualify their customers’ needs accurately, leading to correct sales and fewer returns.

Conclusion

High-speed deep groove ball bearings are specifically needed when the dn value exceeds 500,000 and low friction, heat management, and precision are paramount, typically in electric motors, spindles, and precision instruments where load is secondary to rotational velocity.

-

Understanding the dn value is crucial for selecting the right bearing for high-speed applications. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn how cage design impacts bearing durability and performance under high-speed conditions. ↩ ↩ ↩ ↩

-

Discover the best lubrication methods to enhance the performance and longevity of high speed bearings. ↩ ↩ ↩ ↩

-

Understanding internal geometry can help in selecting bearings that minimize vibration and enhance efficiency. ↩ ↩ ↩ ↩ ↩

-

Discover how special seals can enhance the performance and lifespan of bearings in challenging environments. ↩ ↩

-

Exploring various bearing types helps in making informed decisions for specific engineering needs. ↩ ↩

-

Discover the significance of the dn value in bearing applications and its impact on performance and reliability. ↩