Dust and dirt don’t just sit on your equipment; they actively seek to destroy it. In a dirty environment, a standard pillow block bearing fails not from load, but from contamination. Grit works its way inside, grinding away at precision surfaces until the bearing seizes, halting your entire production line.

For high dust conditions, select pillow block bearings with superior sealing systems (like triple-lip or labyrinth seals), choose a self-aligning spherical roller bearing insert for heavy loads, ensure ample grease capacity for purging, and opt for a robust cast iron housing. This combination protects against ingress and ensures longevity.

Selecting the right bearing is more than just matching a part number. It’s about building a defense system against your specific operating conditions. The wrong choice leads to constant downtime and replacement costs. The right choice gives you reliability. Let’s break down the selection process into clear, actionable steps.

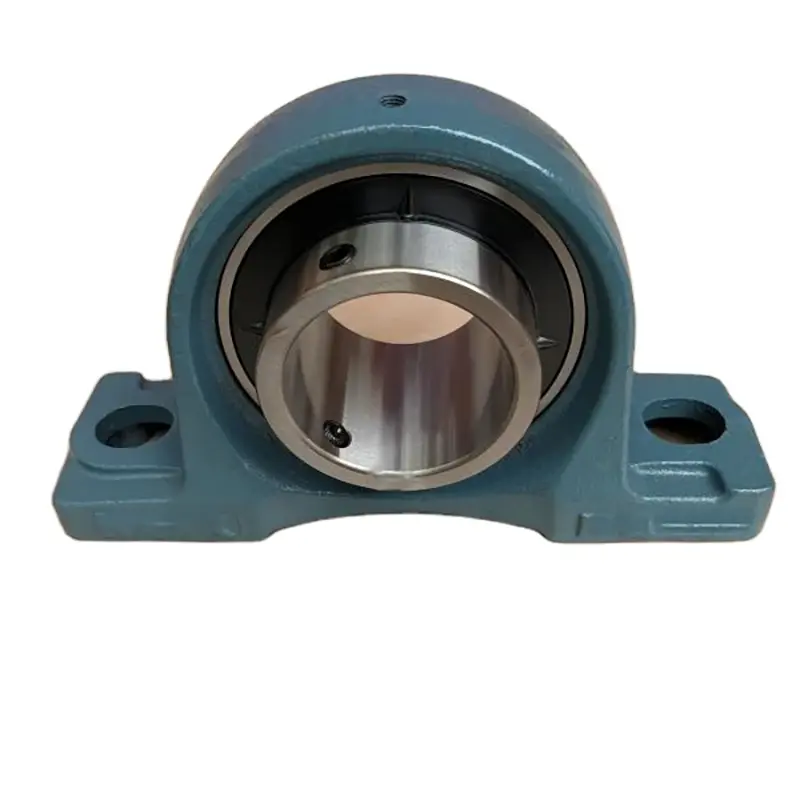

How to select a pillow block bearing1?

Many people select a pillow block by shaft size2 alone. This is a mistake. A bearing that fits the shaft might fail quickly if it cannot handle the environment. Selection is a process of matching several key factors to your application’s reality.

You select a pillow block bearing1 by first determining the shaft size2 and load type (radial/axial). Then, consider the operating environment3 (dust, moisture, temperature) to choose the seal type. Next, select the appropriate bearing insert type4 (ball, spherical roller) for the load and speed. Finally, confirm the housing material5 and mounting style suit your machine frame.

A Structured Selection Framework for Real-World Conditions

Selecting a pillow block is not guesswork. It is a logical sequence of decisions. Each decision narrows down the options until you find the optimal unit. For dirty environments, we must give extra weight to the factors that fight contamination. Let’s build this framework step by step.

Step 1: Define the Basic Parameters (Shaft & Load)

This is your starting point. You must know:

- Shaft Diameter (d): Measure the shaft accurately. This determines the bore size of the bearing insert (e.g., 25mm, 1 inch).

- Load Characteristics:

- Radial Load (Pᵣ): The primary weight or force perpendicular to the shaft. Is it steady, variable, or shock load?

- Axial Load (Pₐ): Any pushing or pulling force along the shaft’s length.

- Speed (n): The rotational speed of the shaft in RPM.

Step 2: Analyze the Operating Environment

This step is critical for dirty conditions. Ask:

- Contamination Level: Is it fine dust, abrasive grit, mud, or slurry?

- Moisture: Is there water splash, steam, or high humidity?

- Temperature: What is the ambient and operating temperature range?

Step 3: Choose the Bearing Insert Type Based on Steps 1 & 2

The insert is the heart of the pillow block. Your load, speed, and environmental needs point to the best type.

| Bearing Insert Type | Best For These Load/Speed Conditions | Suitability for Dirty Environments |

|---|---|---|

| Deep Groove Ball Bearing | Moderate radial & axial loads, higher speeds. | Fair. Requires excellent sealing. Good for lighter dust if well-sealed. |

| Spherical Roller Bearing | Very high radial loads, moderate axial loads, low-to-medium speeds, misalignment. | Excellent. Robust design, often used in heavy-duty dirty apps (mining, ag). |

| Tapered Roller Bearing | High combined radial & axial loads (one direction), medium speeds. | Good. But sensitive to misalignment and requires precise sealing. |

| Cylindrical Roller Bearing | Very high pure radial loads, high speeds. | Poor. Complex seals needed, cannot handle misalignment common in harsh settings. |

Step 4: Specify the Sealing Solution

This is your primary defense. For high dust, never use an open or lightly shielded bearing.

- Contact Seals (e.g., Rubber Lip Seals): Provide a physical barrier. Look for triple-lip seals for superior protection. They create multiple barriers for dust and moisture.

- Labyrinth Seals: Non-contact, complex paths that block contaminants. Often used with grease purging. Excellent for very abrasive, dry dust.

- Combination Seals: A labyrinth with a grease purge fitting and a contact lip. This is often the best choice for severe conditions.

Step 5: Finalize Housing and Mounting

- Housing Material: Choose cast iron for strength, vibration damping, and durability. Pressed steel is lighter but less robust.

- Locking Method: Eccentric locking collars are simple and robust for dirty environments. Set screws can clog with dirt.

- Relubrication: Ensure the unit has a standard grease fitting (zerk) and a clear relief path for purging old grease.

In our factory, when an equipment maker from South Africa sends us their requirements for a conveyor in a coal mine, we follow this exact process with them. We don’t just quote a price. We recommend a specific configuration: a cast iron SN housing, a spherical roller bearing6 insert with C3 clearance, and a triple-lip contact seal with a grease purge. This consultative approach is part of our OEM service and helps distributors like Rajesh provide expert advice to their customers.

What bearings are best for heavy loads?

Heavy loads test the very structure of a bearing. A bearing not designed for heavy loads will suffer from plastic deformation. This means the rollers or balls will permanently dent the raceways, creating vibration, noise, and a rapid path to total failure.

For pillow block applications with heavy radial loads, spherical roller bearing inserts1 are the best choice. They offer the highest radial load capacity due to line contact, can handle moderate axial loads from both directions, and their self-aligning feature protects against misalignment-induced stress concentrations.

Why Spherical Rollers Dominate in Heavy-Duty Pillow Blocks

The superiority of spherical roller bearings in heavy-load scenarios is rooted in physics and design. When we talk about "heavy loads" in industrial settings—like on a vibrating screen or a rock crusher conveyor—we are usually talking about high radial forces, potential shock, and less-than-perfect alignment. Spherical rollers are engineered for this exact combination.

First, consider load capacity and contact type2. A ball bearing has point contact. A spherical roller bearing has line contact. Imagine pressing a pin versus a ruler against your skin. The ruler (line contact) distributes the force over a much larger area. This dramatically reduces the stress on the raceway material. The bearing’s dynamic load rating3 (C) is therefore much higher for a given size.

Second, consider misalignment. In real machinery, especially under heavy load, shafts deflect and housings can warp. A rigid bearing like a cylindrical roller bearing sees this as misalignment. The load then concentrates on a small edge of the roller, causing extremely high localized stress (edge loading). This leads to premature spalling. The spherical roller bearing pivots within its spherical outer ring raceway, maintaining full line contact and even load distribution. This self-alignment is a built-in survival mechanism.

Let’s compare the heavy-load contenders for pillow blocks4:

| Bearing Insert Type | Radial Load Capacity | Axial Load Capacity | Tolerance for Misalignment | Typical Limiting Speed |

|---|---|---|---|---|

| Spherical Roller Bearing | Very High (Best) | Good (Both Directions) | Excellent (2-3°) | Low to Medium |

| Cylindrical Roller Bearing | Very High | Very Low | Poor (Nearly 0°) | Medium to High |

| Tapered Roller Bearing | High | High (One Direction) | Poor (Requires precise setup) | Medium |

| Deep Groove Ball Bearing | Moderate | Moderate (Both Directions) | Poor | High |

For a dirty environment, this comparison becomes even clearer. A cylindrical roller bearing, while having high radial capacity, is a poor choice because it cannot handle misalignment and is very sensitive to contamination in its precise roller-guide flanges. A tapered roller bearing is excellent for defined loads but requires precise adjustment and sealing; dirt can disrupt its preload.

Therefore, for a pillow block on a conveyor in a quarry, the spherical roller bearing is the undisputed champion. Its robust design, combined with a well-sealed housing, provides the necessary load-carrying muscle and environmental resistance5. At FYTZ, we supply these as complete units. Our integrated production means we control the quality of both the spherical roller insert and the cast iron housing, ensuring they work together perfectly to deliver the promised load capacity to our clients in the mining and construction sectors worldwide.

Which is the best bearing for quieter operation at high-speed?

Noise in a bearing is more than an annoyance; it’s a symptom. In a high-speed application, excessive noise often points to vibration, poor lubrication, or impending failure. A quiet bearing is a healthy, efficient, and long-lasting bearing.

For quieter operation at high speeds in a pillow block, deep groove ball bearings with precision grades (P5, P6) are typically the best choice.1 They generate less friction and vibration than roller bearings at high RPMs. Angular contact ball bearings are also excellent for very high-speed, precision applications where axial loads are present.

Balancing Speed, Noise, and Environmental Challenges

The quest for quiet, high-speed operation presents a different set of priorities compared to heavy-load selection. Here, friction, heat generation, and precision become paramount. However, we cannot ignore the environment. A bearing perfect for a clean laboratory may fail instantly in a dusty factory.

First, understand why ball bearings are quieter at high speed2. Their point contact creates lower rolling friction than the line contact of a roller bearing. Less friction means less heat and less vibration—the primary sources of bearing noise. Furthermore, deep groove ball bearings can be manufactured to very high precision classes (ABEC/P5/P6). These bearings have extremely tight tolerances on dimensions and running accuracy (runout). This results in smoother rotation with minimal "wobble" or vibration.

Now, let’s evaluate the options for high-speed pillow blocks, considering both performance and harsh environment suitability:

| Bearing Type for High Speed | Noise & Speed Performance | Suitability for Dusty/Dirty Conditions |

|---|---|---|

| Deep Groove Ball Bearing (Precision P5/P6) | Excellent. Lowest friction, suitable for very high speeds, inherently quiet. | Good, if well-sealed. This is the most common choice for sealed, high-speed industrial fans, pumps, and blowers in moderately dirty environments. |

| Angular Contact Ball Bearing | Superior for very high-speed with axial load. Can be preloaded for ultra-stiff, quiet operation. | Fair to Good. Requires complex sealing. Common in machine tool spindles, which are usually in controlled environments. |

| Cylindrical Roller Bearing (Precision) | Good for high radial speed, but generates more noise than ball bearings. | Poor. Very sensitive to contamination and misalignment. |

| Spherical Roller Bearing | Poor. Higher friction and mass limit speed and increase noise. | Excellent. But chosen for load, not for high-speed quiet operation. |

The critical link is the seal. A high-speed bearing needs a seal that provides protection without creating too much friction. For this, non-contact labyrinth seals3 or low-friction, lightly loaded contact seals are used. A standard heavy-duty triple-lip seal might create too much drag and heat at very high RPMs.

Therefore, the selection becomes a compromise. For a high-speed industrial exhaust fan in a dusty cement plant4, the best practical choice is often a pillow block with a deep groove ball bearing insert (P6 precision) housed in a unit with effective labyrinth or dual-lipped seals. This balances the need for speed and quietness with the need for dust protection.

At FYTZ, we offer this configuration. We can assemble pillow blocks with our low-noise, P5/P6 precision deep groove ball bearings5. For a client in Vietnam manufacturing industrial blowers, this is a key requirement. We ensure the seals are appropriate for the specified speed to prevent overheating. This attention to application-specific details is what differentiates a generic supplier from a technical partner.

What protects the bearings from dirt and moisture?

A bearing’s seals1 are its immune system. When this system fails, contaminants invade. Abrasive particles act like sandpaper, cutting into smooth raceways. Water washes away lubricant and causes rust. The result is always the same: increased wear, heat, and catastrophic failure.

Bearings are protected from dirt and moisture primarily by seals1 integrated into the pillow block housing. These can be contact seals2s](https://www.bdsbearing.com/blog/guide-to-bearings-seals-types-functions-and-applications)[^1] (rubber lips pressing against the shaft), labyrinth seals1 (complex non-contact paths), or a combination of both. Additional protection comes from the housing itself, proper grease purging3, and sometimes external protective covers4.

The Multi-Layer Defense Strategy Against Contamination

Protection is not a single feature; it is a system. Relying on just one layer is risky. In a high-dust environment, you need a defense-in-depth strategy. Each layer has a specific role in stopping or managing contaminants before they reach the bearing’s rolling elements.

Layer 1: The Housing and Static Seals

The pillow block housing itself is the first barrier. The fit between the housing and the bearing outer ring should be tight to prevent "breathing"—where dust is sucked in due to pressure changes from temperature. Gaskets or O-rings between housing halves provide static sealing.

Layer 2: The Primary Dynamic Seal (The Critical Layer)

This seal sits where the shaft rotates through the housing. Its job is to block contaminants at this moving interface.

| Seal Type | How It Protects | Best For | Drawbacks |

|---|---|---|---|

| Lip Contact Seals (NBR, FKM rubber) | A flexible lip presses against the shaft, forming a physical wipe. Multi-lip designs (e.g., Triple-Lip) create multiple barriers. | Excellent for fine dust, mud, slurry. Provides the most positive seal. | Creates friction, can wear the shaft, generates heat at very high speeds. |

| Labyrinth Seals | A complex, narrow gap with grooves that fill with grease. Contaminants must change direction many times to enter. | Excellent for dry, abrasive dust. Very low friction, no wear. | Less effective against pressurized water or fine slurry. Requires grease barrier. |

| V-Ring Seals | A rubber ring that spins with the shaft, flinging contaminants outward centrifugally. | Good for repelling water and coarse dirt. Simple, effective. | Must be installed correctly. Less effective against fine, pervasive dust. |

Layer 3: Grease as a Barrier and Purge Agent

Grease is not just a lubricant; it is a sealant. In a greased-for-life or re-lubricatable pillow block, the grease fills cavities and creates a viscous barrier. More importantly, with a grease fitting and a relief hole, you can perform purging re-lubrication. New grease is pumped in under pressure. It flows through the bearing, picks up fine contaminants, and pushes the old, dirty grease out through the seal relief. This actively cleans the bearing interior.

Layer 4: External Protection (For Extreme Cases)

In the most severe environments, like a mining crusher, additional measures are used:

- Protective Covers: Metal or rubber covers that bolt over the seal area.

- Grease Purge Systems: Automated systems that inject a small amount of grease at intervals to maintain positive pressure inside the housing, pushing contaminants out.

For our clients building equipment for harsh climates—like a manufacturer of agricultural tractors for Russia or road sweepers for the Middle East—we emphasize the seal specification. We might recommend a pillow block with a labyrinth seal combined with an inner lip seal and a grease purge port. This multi-layer approach ensures protection even if one layer is compromised. For distributors, understanding this allows them to stock and recommend the right protection level. A customer with a mildly dusty warehouse needs a standard lip seal. A customer with a sand and gravel plant needs the heavy-duty combination. Selling the correct protection builds trust and prevents premature failures.

Conclusion

Selecting the right pillow block for dirty conditions means prioritizing superior sealing (like triple-lip or labyrinth), choosing a robust bearing insert (spherical roller for load, precision ball for speed), and ensuring the housing and lubrication system support a proactive defense against contamination.

-

Understanding seal types can help you choose the right protection for your bearings. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn how contact seals provide effective protection against contaminants in bearings. ↩ ↩ ↩ ↩ ↩

-

Explore the significance of grease purging in maintaining bearing performance and cleanliness. ↩ ↩ ↩ ↩

-

Learn about protective covers and their importance in extreme environments for bearings. ↩ ↩ ↩ ↩

-

Explore the features of low-noise bearings that make them ideal for high-speed industrial applications. ↩ ↩ ↩

-

Spherical roller bearings offer unique benefits for heavy-duty applications, making them worth exploring. ↩