In an office, hospital, or hotel, a noisy fan bearing is more than a maintenance issue. It’s a complaint waiting to happen, signaling poor quality and discomfort.

For quieter operation in HVAC and ventilation fans, choose deep groove ball bearings with a polyamide (PA66) cage (suffix TN9), higher precision grades (P6 or P5), optimized internal geometry, and proper internal clearance (C3). These features reduce vibration and mechanical noise, which is critical for acoustic comfort in buildings.

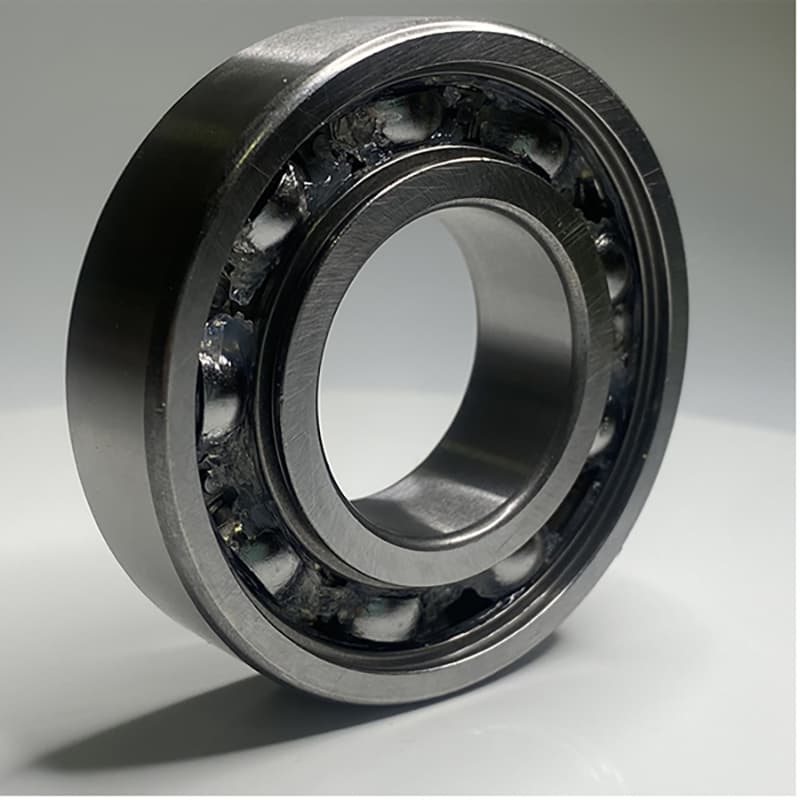

HVAC systems are designed for human comfort, and noise is a primary enemy of comfort. The fan motor and its bearings are often the main source of mechanical noise in the system. While all deep groove bearings are relatively quiet compared to roller bearings, there is a specific subset engineered for "low-noise" or "quiet-running" performance. For OEMs building fans and for maintenance buyers like Rajesh, selecting these specialized bearings is a key differentiator. Let’s explore what makes a bearing quiet and how to choose the right one.

This is the core question for any noise-sensitive application. The answer lies in specific design and manufacturing choices, not just the bearing type.

A deep groove ball bearing with a polyamide (plastic) cage1 (e.g., suffix TN9), higher precision grade2 (P6 or better), optimized raceway finishing, and proper lubrication will run quieter than a standard bearing with a steel cage and normal precision. The cage material is often the most significant factor in reducing audible noise.

Quiet operation isn’t an accident. It’s the result of mitigating specific sources of vibration and sound within the bearing.

Bearing noise is essentially vibration in the audible frequency range. Let’s identify the sources and the bearing features that control them.

Primary Sources of Bearing Noise

How Low-Noise Bearings Address These Issues

A Practical Selection Guide for Quieter Fans

| Bearing Specification | Standard Bearing | Low-Noise Bearing for HVAC | Why It’s Quieter |

|---|---|---|---|

| Cage Type | Stamped Steel (no suffix or J/ JJ) | Polyamide Cage (TN9) | Damping, lighter weight, reduced impact. |

| Precision Grade | P0 (Normal, often unmarked) | P6 or P5 | Tolerances reduce vibration from runout. |

| Internal Clearance | CN (Normal) | C3 (or sometimes CM, a special motor clearance) | Prevents preload-induced noise from heat. |

| Seals | ZZ (Shields) or 2RS (Rubber Seals) | 2RS (with low-friction lip design) | Rubber seals can dampen some vibration compared to ZZ. Avoids grease churn. |

| Vibration Level | Z3 or unclassified | Z1 or Z2 (Lower vibration class) | Manufacturer-tested and graded for low vibration. |

For Rajesh, this is a clear value proposition. When a fan manufacturer or maintenance company asks for a "quiet bearing," he shouldn’t just send a standard 6205-2RS. He should recommend a 6205-2RS TN9 P6 or a similar variant from FYTZ’s low-noise series. This targeted recommendation solves the customer’s core problem (noise) and justifies a potential price premium with a clear technical benefit.

This is a common question from engineers and buyers influenced by brand reputation. However, for HVAC applications, "better" must be defined by specific performance needs and value.

Neither NSK nor SKF is universally better. Both are top-tier manufacturers with excellent quality. The "better" choice depends on specific factors like availability, technical support, price for the required specification (e.g., low-noise TN9 P6), and the exact bearing series needed. For many HVAC applications, a high-quality bearing from a reliable supplier like FYTZ, meeting the same low-noise specifications, can provide equal performance and better value.

The brand debate often overshadows the more critical discussion about specifications. In the global bearing market, many factories produce bearings to identical international standards.

NSK (Japan) and SKF (Sweden) have earned their reputations through decades of innovation and consistent quality. However, for a standard deep groove ball bearing in an HVAC fan, the performance difference between their equivalent products (e.g., both offering a 6205-2RS TN9 P6 C3) is often negligible for the application.

What Really Matters for HVAC Fan Bearings?

The Role of Quality Manufacturers like FYTZ

Factories like FYTZ in China produce bearings to the same ISO standards (ISO 15 for dimensions, ISO 281 for load ratings). We have integrated production lines and inspection equipment. For the HVAC market, we produce dedicated low-noise series that directly compete with the standard offerings from NSK and SKF.

A Strategic Perspective for Distributors and Buyers

For Rajesh, competing on brand alone against NSK or SKF is difficult. His strategy should be to compete on specification and value.

Ultimately, for an HVAC fan running 24/7, the bearing that reliably delivers low noise and long life at a fair price is the "better" bearing, regardless of the logo on its shield.

This question contains a common misconception. "Deep groove" is a standard type of ball bearing. The real comparison is between a generic standard bearing and a specialized deep groove bearing for a specific purpose like low-noise.

All deep groove ball bearings are a "standard" type of radial ball bearing. The key difference lies in the specifications within that type. A ‘standard’ off-the-shelf deep groove bearing might have a steel cage and normal precision (P0). A specialized low-noise deep groove bearing for HVAC will have a polyamide cage (TN9), higher precision (P6), and possibly optimized internal geometry for quieter operation.

The term "standard" is ambiguous. In bearing catalogs, it often refers to the most common, no-frills variant of a given type. Let’s clarify the spectrum.

Think of "deep groove ball bearing" as a car model. The "standard" model has basic features. The "quiet" or "low-noise" model has upgraded sound insulation, a smoother engine, and better tires.

The "Standard" Deep Groove Ball Bearing (Common Catalog Item)

The "Low-Noise" or "Quiet-Running" Deep Groove Ball Bearing (Specialized Variant)

Key Takeaway for Buyers

The physical dimensions (bore, OD, width) of a standard 6205 and a low-noise 6205 are identical. They are directly interchangeable on the shaft and in the housing. The difference is entirely in the internal components and manufacturing tolerances, which affect performance, not fit.

Impact on Procurement

For Rajesh, this means his inventory strategy should reflect his market. If he supplies mostly to heavy industry, standard bearings are his bread and butter. If he targets the growing HVAC and appliance repair market in cities like Mumbai and Bangalore, he needs to stock the low-noise variants. He must educate his customers: "For your fan motor repair, you need a 6205-2RS, but to make it quiet, you should get the version with the plastic cage and P6 precision. It costs a little more but will keep the noise down." This builds his reputation as a specialist in comfort-driven applications.

HVAC bearings1 aren’t a unique bearing type; they are deep groove ball bearings2 selected and sometimes customized for the specific demands of heating, ventilation, and air conditioning equipment.

HVAC bearings1 are deep groove ball bearings2 optimized for the environmental and operational needs of fans and blowers. They prioritize low noise, long life at continuous operation, resistance to temperature fluctuations, and often have enhanced sealing to handle humidity and light dust. Common specifications include polyamide cages (TN9), C3 clearance, and P6 precision.

They are workhorse components in a multi-billion dollar industry. Their failure means loss of climate control, comfort, and in some cases, safety (e.g., hospital ventilation).

Let’s examine why standard industrial bearings might not be ideal and what makes an "HVAC-optimized" bearing.

Operating Environment and Challenges:

| How Bearings are Optimized for HVAC Duty | Challenge | Bearing Solution | Reason |

|---|---|---|---|

| Low Noise | Polyamide (PA66) Cage (TN9), P6 Precision. | Dampens vibration, reduces audible hum from cage and ball passage. | |

| Long Life, Continuous Run | High-quality vacuum-degassed steel, optimized internal geometry. | Maximizes fatigue life under constant load. Stable grease for long lubricant life. | |

| Thermal Cycles | C3 Internal Clearance. | Prevents preload and noise when the inner ring expands from motor heat. | |

| Humidity & Contamination | Effective Sealing (2RS with good lip design). | Keeps moisture and light dust out, retains grease. In very humid environments, stainless steel versions may be used. | |

| Maintenance-Free Operation | Pre-greased, Sealed-for-Life design (2RS). | Most HVAC fan bearings are not designed for re-lubrication. They must last the design life of the unit (often 5-10 years) without service. |

Common HVAC Bearing Applications

Sourcing and Supplying HVAC Bearings

For a distributor, the HVAC market is attractive. It’s large, has recurring replacement demand, and values technical specification over pure lowest price.

By understanding that "HVAC bearings1" are a performance-specific subset of deep groove ball bearings2, Rajesh can position himself as a knowledgeable supplier for a profitable and growing niche.

Selecting the right bearing for HVAC and ventilation fans requires moving beyond generic deep groove bearings to specify low-noise variants with polyamide cages, higher precision, and appropriate clearance. Focusing on these performance-driven specifications, rather than brand names alone, ensures quiet, reliable operation and delivers the acoustic comfort that defines quality in modern building systems.

Explore this link to understand the specific features and applications of HVAC bearings in climate control systems. ↩ ↩ ↩ ↩ ↩

Learn about deep groove ball bearings and their versatility in various applications, including HVAC systems. ↩ ↩ ↩ ↩

Understand the sources of cage noise and effective solutions to minimize it. ↩

Discover the role of lubrication in bearing performance and noise reduction. ↩

Explore the unique benefits of polyamide cages in reducing noise and vibration. ↩

Find out how super-finishing improves bearing smoothness and reduces noise. ↩

Learn how internal geometry design enhances bearing efficiency and quiet operation. ↩

Understand the importance of selecting the right grease for quieter bearing operation. ↩