Choosing the wrong seal is the fastest way to kill a perfectly good bearing. Contamination doesn’t wait for you to notice the mistake.

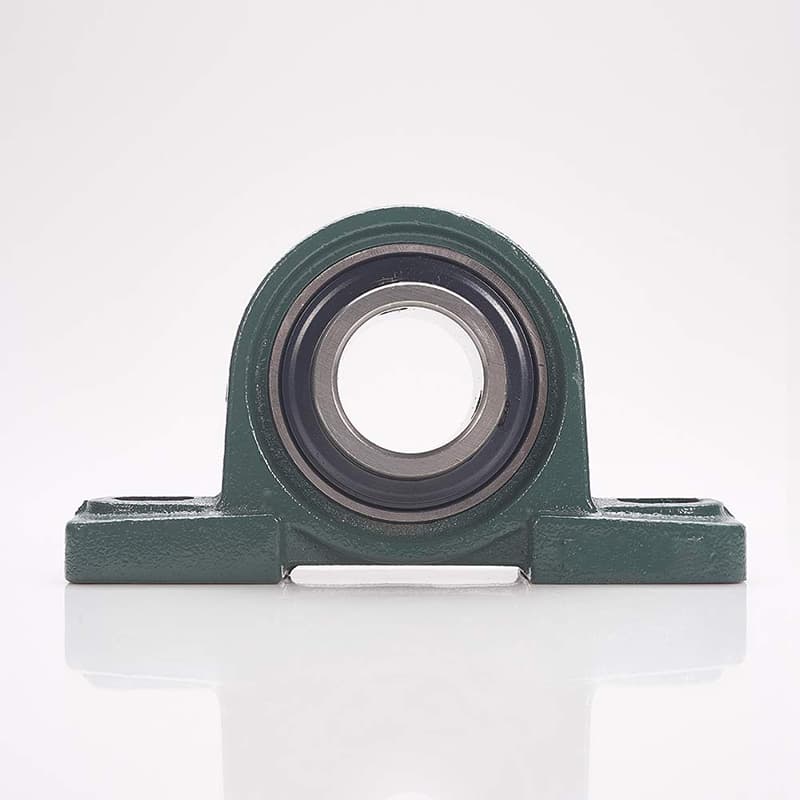

Pillow block bearings come with various sealing options: standard lip seals for general dust, triple-lip seals for better protection in dirty/wet environments, and non-contact labyrinth seals for high-speed or harsh contaminant exclusion. The correct seal choice directly determines bearing life in any given application.

The bearing inside a pillow block can be identical, but its lifespan can vary by 500% or more based solely on the seal that protects it. Seals are the gatekeepers. They keep lubricant in and contaminants out. In the real world of factories, farms, and processing plants, the environment is rarely clean. Understanding sealing options isn’t a minor detail; it’s a primary factor in achieving reliable, low-maintenance operation. Let’s explore the common types and how to choose.

Are pillow block bearings sealed?

This is a common point of confusion. Buyers often assume a "pillow block" is a sealed unit, but the reality is more nuanced and crucial for selection.

Most standard pillow block bearings (like UCP, UCFL series) come pre-lubricated and equipped with some form of seal or shield, typically contact lip seals. However, the level of protection varies widely. "Sealed" does not mean "waterproof" or "maintenance-free forever." The seal’s effectiveness depends entirely on its design and the operating environment.

The short answer is yes, but the critical question is: "How well are they sealed, and is it enough for my specific conditions?" Let’s clarify what "sealed" really means.

Understanding the Spectrum of "Sealed" Protection

When a catalog says a pillow block is "sealed," it typically refers to the bearing insert being protected. The housing itself provides additional, but not perfect, environmental protection.

The Two Layers of Defense

- Bearing Insert Seals/Shields: This is the primary seal. It is attached to the bearing itself and rotates with the inner ring or is fixed to the outer ring.

- Shields (ZZ): Metal plates with a small gap. Keep out large debris but allow grease to potentially leak and contaminants to slowly ingress. For clean, high-speed applications.

- Contact Lip Seals (2RS): Rubber lips that press against a sealing land. Provide good protection against dust and some moisture. Common in standard pillow blocks.

- Housing Design & Auxiliary Seals: The pillow block housing has gaps where the shaft enters. Some housings have additional built-in labyrinth paths or grooves to make contaminant entry more difficult.

What "Sealed" Does NOT Mean

- It does not mean submersible. A standard lip seal will fail quickly under direct water spray or immersion.

- It does not mean it excludes fine dust. Fine abrasive powders can work their way past a standard single-lip seal over time.

- It does not eliminate maintenance. Grease eventually degrades. The seal itself can wear out. Relubrication may still be necessary and possible through a grease fitting.

The Practical Implication for Buyers

For someone like Rajesh, this is a key sales conversation. When a customer in a flour mill asks for a "sealed UCP 205," Rajesh needs to ask about the environment. If the mill is very dusty, the standard seal may not be sufficient. He should then recommend a pillow block with enhanced sealing, such as a triple-lip seal option. By clarifying that "sealed" has grades, he prevents a premature failure and provides a better solution. At FYTZ, we offer pillow blocks with different seal grades, so our distributors can match the product to the need, not just sell a standard part.

What is the difference between labyrinth seal and lip seal?

This is the classic choice between a non-contact, low-friction defender and a contact, high-security guard. Each has a dominant territory.

A lip seal uses a flexible rubber lip that contacts the shaft or a sealing land to create a physical barrier, offering good sealing but with friction and wear. A labyrinth seal uses a series of narrow, non-contact gaps and turns to create a tortuous path that blocks contaminants, offering excellent protection with virtually no friction, but it is more complex and typically larger.

The core difference is contact. This single difference drives all other performance characteristics, making each seal ideal for opposite types of applications.

A Head-to-Head Comparison of Principles and Performance

Let’s break down how each seal works and where it excels or fails.

Lip Seal (Contact Seal)

- Principle: A molded rubber ring with one or more flexible lips. The lip is spring-loaded or designed to press tightly against a smooth shaft surface or a dedicated sealing land on the inner ring.

- How it Works: The contact creates a wiping and blocking action. It physically scrapes contaminants off the shaft and blocks their entry.

- Advantages:

- Effective sealing against dust, dirt, and light splashes.

- Helps retain grease inside the bearing.

- Compact and relatively inexpensive.

- Simple design.

- Disadvantages:

- Friction: Contact creates drag, which increases with speed and generates heat. This limits maximum operating speed (lower

dm•nvalue). - Wear: The lip wears over time, reducing sealing effectiveness. It can wear a groove into the shaft.

- Heat Sensitivity: Standard rubber (NBR) lips harden and crack at high temperatures (>100°C).

- Pressure Sensitivity: Can be deformed by external pressure, breaking the seal.

- Friction: Contact creates drag, which increases with speed and generates heat. This limits maximum operating speed (lower

Labyrinth Seal (Non-Contact Seal)

- Principle: Two interlocking metal (or plastic) components with a very small, zigzag gap between them. One part rotates with the shaft, the other is stationary in the housing.

- How it Works: Contaminants (dust, water) must navigate a long, narrow, changing-direction path to enter. Centrifugal force throws particles outward. The design does not rely on tight contact.

- Advantages:

- Very low friction and heat generation, allowing for very high speeds.

- Excellent long-term reliability with no wearing parts in contact.

- Effective against fine dust, water spray, and even some pressurized contaminants.

- Handles high temperatures well (metal construction).

- Disadvantages:

- Does not positively retain grease; grease can slowly migrate out.

- Generally larger and more expensive than lip seals.

- More complex to manufacture and assemble.

- Less effective in submerged or high-pressure jet conditions without special designs.

Application-Based Decision Guide

| Application Environment | Recommended Seal Type | Why? |

|---|---|---|

| General factory, moderate dust | Single or Double Lip Seal (2RS) | Cost-effective, good enough protection. |

| Food & Beverage washdown, frequent hosing | Triple-Lip Seal or PTFE Lip Seal | Multiple barriers against water, chemical resistance. |

| Very dusty environment (cement, grain, mining) | Labyrinth Seal | Stops fine abrasive dust without wear. Can be purged with grease. |

| High-speed fan, turbine, or motor | Labyrinth Seal or Non-Contact Isolator | Minimal friction prevents overheating at high RPM. |

| Submerged or extreme pressure wash | Mechanical Face Seal | Creates a positive seal through axial pressure. |

Sourcing and Specification Advice

For distributors, this knowledge is critical for inventory. Rajesh should stock standard lip-seal pillow blocks for general purpose sales. But for key industrial sectors in his region—like mining in South Africa or food processing in Vietnam—he should also stock or be able to source units with labyrinth or triple-lip seals. When a mining customer complains about short bearing life on a conveyor, Rajesh’s first question should be about dust. His first recommendation should be to upgrade to a labyrinth-sealed pillow block. This targeted advice solves the root problem.

What is the standard seal for insert bearings?

Insert bearings are the removable core of a pillow block. Their standard sealing sets the baseline for the entire unit’s protection.

The standard seal for most common insert bearings (like those in UCP, UCF series pillow blocks) is the RS type, specifically a low-friction, nitrile rubber (NBR) contact lip seal on one or both sides. "2RS" means two rubber contact seals, which is the typical, factory-filled, and "sealed-for-life" configuration for these units.

When you order a standard pillow block off the shelf, the bearing inside will almost certainly have this type of seal. It’s the industry’s default for a reason, but knowing its limits is key.

The Anatomy and Performance of the Standard RS Seal

The "RS" seal is a workhorse design. Understanding its construction helps you predict where it will succeed and where it will need help or replacement.

Construction Details

- Material: The sealing lip is typically made of Nitrile Butadiene Rubber (NBR). This is a good all-purpose elastomer with decent resistance to oils, greases, and moderate temperatures (up to ~100°C continuous).

- Design: The seal is a steel-reinforced rubber ring. The lip is often angled and may have a light spring (garter spring) behind it to maintain contact pressure against the shaft. In "low-friction" RS designs, the lip contact pressure is optimized to balance sealing and drag.

- Configuration:

- RS: A seal on one side. Rare for pillow blocks.

- 2RS or 2RSA: Seals on both sides. This is the standard. The bearing is pre-greased and considered "sealed for life" under good conditions.

Performance Profile of the Standard Seal

- Protection Level: Good protection against coarse to medium dust and dirt. Fair protection against light splashes and occasional moisture. Poor protection against fine abrasive dust, direct water jets, steam, or chemical splashes.

- Speed Limitation: The contact creates friction. This limits the permissible speed of the bearing compared to an open or shielded (ZZ) version. The

dm•nvalue for a 2RS bearing is lower. - Temperature Range: Standard NBR is suitable for -30°C to +100°C. For higher temperatures, seals made from Fluorocarbon (FKM/Viton) or Acrylic (ACM) are used, but they are not "standard" and must be specified.

- Chemical Compatibility: NBR is resistant to many mineral oils and greases but can be attacked by certain chemicals, solvents, and ozone.

When the "Standard" Seal is Not Enough

The standard 2RS seal is adequate for probably 60% of industrial applications: indoor machinery, light-duty conveyors, fans in clean environments. Failure occurs when it is used outside its design envelope. Common mismatch scenarios include:

- Using a standard UCP block on an agricultural implement exposed to mud and rain.

- Using it on a sawmill conveyor exposed to fine sawdust.

- Using it in a food processing line with daily high-pressure washdowns.

The Upgrade Path

When the standard seal is insufficient, you don’t need a different bearing; you need a different seal configuration on the same bearing. This is where options come in:

- Upgraded Lip Seals: Triple-lip seals (often denoted as TTS or similar) provide multiple barriers. PTFE (Teflon) lip seals offer chemical resistance and can handle drier environments.

- Non-Contact Seals: As discussed, labyrinth seals can be added to the housing or as part of a specialized end cover.

- Hybrid Solutions: Some pillow blocks have a labyrinth path built into the housing, combined with a standard lip seal on the bearing itself, creating a two-stage defense.

For Rajesh, this means his catalog should list pillow blocks not just by size (UCP 205), but by seal type (e.g., UCP 205-2RS Standard, UCP 205-TTS Triple Lip, UCP 205-LAB Labyrinth). This allows his customers to select the exact level of protection they need, and it allows Rajesh to capture more value by selling the appropriate solution rather than the cheapest part.

What do z and zz mean on a bearing?

These are the most basic sealing/shielding codes. They appear on bearing packages and stamps, and misunderstanding them leads to misapplication.

"Z" means a metal shield on one side of the bearing. "ZZ" or "2Z" means metal shields on both sides. Shields are non-contact metal plates that keep out large debris and contain grease, but they do not provide a tight seal. They are for clean, high-speed applications where low friction is critical.

Z and ZZ are about containment and coarse exclusion, not true sealing. Choosing ZZ when you need RS is a guaranteed path to contamination failure.

Decoding Shield Designations and Their Proper Use

Shields and seals are fundamentally different. Confusing them is a common and costly error in bearing selection.

Detailed Look at Metal Shields (Z, ZZ)

- Construction: A thin steel plate is stamped and pressed into a groove on the bearing’s outer ring. There is a very small running clearance (a few tenths of a millimeter) between the shield and the inner ring. It does not touch.

- Function:

- Containment: Primarily, it keeps the bearing’s pre-packed grease from easily leaking out.

- Coarse Exclusion: It blocks large chunks of debris (like wood chips, large dirt particles) from entering the bearing.

- What it Does NOT Do:

- It does not keep out fine dust, powder, or moisture. These can easily pass through the gap.

- It does not provide a positive seal against water or chemical splash.

- Advantages:

- Very low friction (non-contact), allowing for the highest possible operating speeds for that bearing type.

- No wear, so performance doesn’t degrade over time.

- Handles higher temperatures than rubber seals.

Comparison with Rubber Seals (RS, 2RS)

| Feature | Metal Shield (ZZ) | Rubber Contact Seal (2RS) |

|---|---|---|

| Contact | Non-contact. Clearance gap. | Contact. Lip rubs on sealing surface. |

| Friction | Very low. Ideal for high speed. | Higher. Limits maximum speed. |

| Protection | Coarse debris only. Fine dust & water can enter. | Good for dust & light moisture. |

| Grease Retention | Good, but grease can slowly migrate out. | Excellent. |

| Temperature | High (metal). | Limited by rubber material (usually <100°C for NBR). |

| Typical Application | Electric motors, indoor gearboxes, clean, high-speed machinery. | General industrial, conveyors, fans, dusty/dirty environments. |

How to Identify and Specify

- The codes are usually stamped on the bearing ring itself. You might see 6208 ZZ (deep groove ball bearing, 40mm bore, two shields) or 6208 2RS (same bearing, two rubber seals).

- In a pillow block catalog, the bearing insert is often specified. A standard UCP block likely contains a 2RS bearing. A block specified for high-speed motors might contain a ZZ or open bearing.

Critical Selection Advice

For a bearing distributor, this is a fundamental consultation point. Rajesh must train his team to ask about speed and environment.

- Scenario A: A customer needs a bearing for a 3000 RPM electric motor repair in a clean factory. Recommend a ZZ or open bearing for low friction and heat.

- Scenario B: A customer needs a bearing for a conveyor idler in a gravel yard. Recommend a 2RS or better sealed bearing. Offering a ZZ bearing here would lead to rapid failure from dust ingress.

Furthermore, Rajesh should be cautious with very low-cost bearings. Sometimes, a bearing stamped "ZZ" might have a shield that is poorly fitted or has excessive clearance, offering almost no protection. Sourcing from a quality-controlled manufacturer like FYTZ ensures that a "ZZ" bearing has the proper, consistent clearance to perform as intended. This attention to detail prevents field failures and protects his reputation.

Conclusion

The sealing system on a pillow block bearing is its first and most important line of defense. Matching the seal type—from standard lip to triple-lip or labyrinth—to the specific contaminants and operating conditions of your application is not an option; it is the fundamental requirement for achieving long bearing life and reliable operation.