A wrong bearing clearance can destroy a perfect machine. I’ve seen it cause overheating, seizure, and catastrophic failures in just hours of operation.

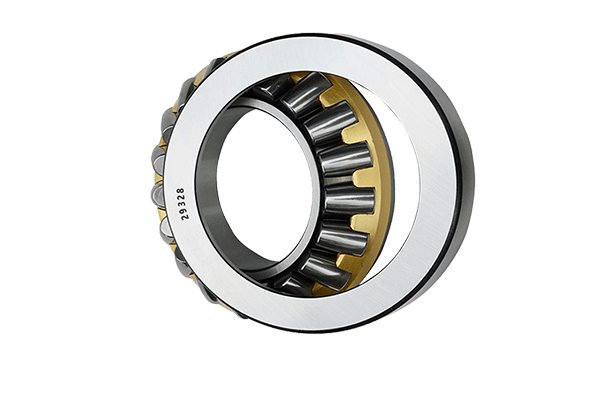

Internal clearance in spherical roller bearings is the space inside the bearing between the rollers and raceways. C3, C4, and C5 are standardized clearance groups, each larger than the previous one. You must specify the correct group to account for operating temperature, shaft fits, and load conditions for optimal bearing life.

Clearance is not just a number on a catalog page. It is a critical operational parameter. If it’s too small, the bearing can overheat and seize under load. If it’s too large, the bearing becomes noisy, loses precision, and suffers from impact loads. For buyers and engineers like Rajesh’s clients, specifying the wrong clearance is a common and costly mistake. This guide will help you choose correctly.

What is C3 and C4 clearance in bearings?

These codes appear on almost every bearing box and specification sheet. But what do they really mean for the performance inside your machine?

C3 and C4 are standardized groups of radial internal clearance (RIC). C3 is a ‘greater than normal’ clearance. C4 is a clearance ‘greater than C3’. They are not exact measurements but ranges that ensure consistent performance across different bearing sizes and manufacturers.

C3 and C4 are not about bearing quality. They are about engineering fit for the application’s environment. Let’s break down the concept.

Demystifying Clearance Groups: From Theory to Practice

Internal clearance is a pre-set condition before the bearing is installed. It directly influences the "operational clearance" after installation and during running.

Understanding the "Standard" (CN) Baseline

First, you need to know what "normal" is. Most bearing catalogs define a "Normal" or "CN" clearance group. This is the standard clearance for a bearing at room temperature with standard fits. C3, C4, and C5 are all measured relative to this "Normal" group. C3 means the bearing is manufactured with internal space that is greater than the Normal range.

Why We Need More Than "Normal" Clearance

A bearing does not operate in a perfect, room-temperature lab. In real machines, several factors reduce the internal clearance after installation:

- Interference Fit: The inner ring is pressed onto a shaft. It expands slightly, reducing clearance. The outer ring is pressed into a housing. It contracts slightly, also reducing clearance.

- Thermal Expansion: When the bearing runs, it gets hot. The inner ring (usually on the faster-rotating shaft) gets hotter than the outer ring (in the cooler housing). This temperature difference makes the inner ring expand more than the outer ring, further reducing clearance.

If you start with a "Normal" clearance bearing, these two factors can consume all the internal space. The bearing can become preloaded (negative clearance). This creates enormous friction and heat, leading to rapid failure.

The Role of C3 and C4

C3 and C4 clearances are "insurance policies." They provide extra internal space from the start. This extra space is designed to be taken up by the interference fit and thermal expansion during operation. The goal is to arrive at a small, positive operational clearance when the machine is running at its normal temperature. This ideal clearance ensures smooth rolling, proper lubrication flow, and long life.

A Practical Example for a Distributor

Imagine Rajesh gets an order from a local sugar mill. They need replacement spherical roller bearings for their large crushing rollers. These rollers have heavy loads and run hot. The original bearings failed from overheating. If Rajesh supplies standard clearance bearings (CN), they will likely fail again. The heat and press-fit will eliminate all clearance. Instead, he should recommend C3 or even C4 clearance bearings. The extra initial space compensates for the harsh conditions. The new bearings will run cooler and last longer. By understanding this, Rajesh moves from being an order-taker to a trusted technical advisor, preventing costly repeat failures for his customer.

What is the difference between C3 and C5 bearings?

C3 is common, but C5 appears in extreme applications. Knowing the difference prevents under- or over-specifying.

The difference between C3 and C5 bearings is the amount of internal space. C5 clearance is significantly larger than C3 clearance. C5 is used in the most severe applications where very high temperatures, heavy interference fits, or shaft/housing materials with different expansion rates are expected.

C5 is not just a "bigger C3." It is a specific solution for specific, demanding problems. Using it where it’s not needed can cause other issues.

Choosing Between C3 and C5: A Decision Guide

This choice is critical. It balances the risk of seizure from too little clearance against the risk of instability from too much clearance.

Quantifying the Difference

While exact values depend on bearing size, the relationship is consistent. For a given bearing bore diameter:

- C3 clearance is typically about 1.5 to 2 times larger than the "Normal" (CN) clearance range.

- C5 clearance is typically about 2 to 3 times larger than the "Normal" (CN) clearance range, and is noticeably larger than C3.

When to Specify C3 Clearance (The Industrial Workhorse)

C3 is the most commonly specified clearance for industrial spherical roller bearings. It is the safe, recommended choice for the majority of applications. Use C3 when:

- The operating temperature is moderately elevated.

- Standard shaft and housing interference fits (like m6 for the shaft, H7 for the housing) are used.

- The machine has expected, moderate shaft misalignment.

- The load is heavy but consistent.

- Examples: Conveyor pulleys, industrial fans, gearboxes, standard pumps, crushers in normal duty.

When to Specify C5 Clearance (The Heavy-Duty Specialist)

C5 is for special, often harsh, conditions. Use C5 when:

- Very High Operating Temperatures: The inner ring runs much hotter than the outer ring. This is common in dryer bearings, kiln supports, or applications near heat sources.

- Very Heavy Interference Fits: The shaft or housing fit is exceptionally tight, which greatly reduces clearance upon installation.

- Dissimilar Materials: The shaft is made of a material (like aluminum) that expands much more than the steel bearing when heated, creating extra squeeze on the inner ring.

- Specific Vibratory Machinery: Some vibratory screen and shaker applications require extra clearance to function correctly and prevent brinelling from oscillating loads.

- Examples: Rotary kiln support rollers, large dryer drums, some types of vibrating screens, marine stern tube bearings.

The Trade-Offs of Larger Clearance

More clearance is not always better. C5 bearings come with compromises:

- Reduced Rotational Accuracy: The larger internal play can lead to more shaft runout or vibration, which is unacceptable in precision spindles.

- Increased Noise: The rollers can move more freely, potentially causing more operational noise.

- Sensitivity to Light Loads: Under very light loads, the bearing might not position the rollers optimally, leading to skidding and wear.

Guidance for Procurement

For a bearing importer like Rajesh, stocking mostly C3 clearance spherical rollers is logical, as it covers 80-90% of industrial needs. However, he should know when to ask his supplier (like FYTZ) for C5. If a customer in the cement or steel industry asks for bearings for a kiln or dryer, Rajesh must inquire about the temperature and fits. Supplying the standard C3 from stock could lead to a failure and a lost customer. We often keep C5 bearings for specific OEM projects or can produce them on demand for our distributors facing these extreme applications.

How much bearing clearance is acceptable?

This is the core question for every maintenance engineer. The answer is not a fixed number, but a "Goldilocks" zone that is "just right."

The acceptable bearing clearance is the ‘operational clearance’ when the machine is running at normal temperature. It should be a small, positive value. This value is achieved by selecting the correct initial clearance group (like C3) that, after accounting for fits and thermal effects, leaves the ideal running gap.

"Acceptable" means the clearance supports long bearing life and stable operation. It is a dynamic target, not a static measurement.

The Journey from Initial to Operational Clearance

To find the "acceptable" zone, you must follow the clearance through three stages.

Stage 1: Initial Clearance (As Manufactured)

This is the C3, C4, or C5 value measured in the box. It is your starting capital.

Stage 2: Installed Clearance (After Press-Fit)

This is the clearance after you press the bearing onto the shaft and into the housing. Interference fits consume a significant portion of the initial clearance. The amount lost depends on the fit tolerances (shaft diameter, housing bore). A tight fit takes more clearance than a loose fit.

Stage 3: Operational Clearance (Running at Temperature)

This is the final, most important clearance. It is the installed clearance further reduced by the differential thermal expansion between the hot inner ring and the cooler outer ring. The goal is for this final value to be slightly greater than zero.

The "Ideal" Operational Clearance

For spherical roller bearings, a good rule of thumb is that the operational radial clearance should be roughly between 0.0001 x d and 0.0003 x d, where d is the bearing bore diameter in millimeters.

- For a 100mm bore bearing: Acceptable operational clearance ≈ 0.01mm to 0.03mm.

This small, positive gap ensures: - All rollers share the load evenly.

- A lubricant film can form properly.

- There is no metallic contact causing friction heat.

- The bearing can accommodate minor misalignment.

Signs of Unacceptable Clearance

| How do you know if the clearance is wrong? Look for these symptoms: | Symptom | Likely Clearance Problem | What Happens Inside |

|---|---|---|---|

| Bearing runs very hot, seizes | Clearance is too small (Negative). | Interference fit and heat used up all space. The bearing is preloaded. Metal-to-metal contact creates extreme friction. | |

| Bearing is noisy, vibrates excessively | Clearance is too large. | Rollers have too much play. They can skid, impact the cage, and cause uneven rolling. The shaft may also have too much movement. | |

| Fatigue failure happens very early | Clearance is wrong (often too small). | Incorrect load distribution causes stress concentrations on a few rollers, speeding up spalling. |

Practical Advice for Buyers and Maintainers

For someone like Rajesh, or his customers doing repairs, here is the simple approach:

- Check the Original Specification: Always try to match the clearance code (C3, C4) of the original bearing that worked well.

- Consider the Operating Environment: If the machine runs hotter than usual, or if you are using a tighter fit, consider the next larger clearance group (e.g., from C3 to C4).

- Consult the Supplier: When in doubt, ask your bearing supplier. At FYTZ, our engineers help distributors like Rajesh analyze the application. We ask about temperatures, speeds, and fits to recommend the correct clearance. This service prevents costly mistakes and builds reliable partnerships.

Which bearing is better, C3 or C4?

Buyers often ask for the "best" bearing. For clearance, "better" depends entirely on the machine’s needs, not the bearing itself.

Neither C3 nor C4 is universally better. C3 is better for standard industrial applications with moderate heat and standard fits. C4 is better for more severe conditions with higher temperatures, heavier fits, or where more misalignment accommodation is needed from the internal clearance.

Calling one "better" is like asking if a winter tire is better than a summer tire. The answer depends on the road conditions. Let’s compare their applications.

A Head-to-Head Comparison for Decision Making

To make an informed choice, we must put C3 and C4 side by side and see where each excels.

Direct Comparison Table

| Feature / Application | C3 Clearance Bearing | C4 Clearance Bearing |

|---|---|---|

| Internal Space | Greater than Normal. | Greater than C3. |

| Typical Use Case | The standard, all-round choice for most heavy machinery. | For more severe or specific conditions. |

| Operating Temperature | Suitable for moderate temperature rise. | Better for high temperature differentials. |

| Shaft/Housing Fit | Compatible with standard interference fits (e.g., m6/H7). | Can accommodate heavier interference fits. |

| Misalignment | Provides some accommodation via clearance. | Provides slightly more internal room for the inner ring to pivot, aiding self-alignment. |

| Risk of Seizure | Low, if applied correctly. | Even lower in severe conditions. |

| Risk of Noise/Play | Low in correct application. | Slightly higher risk if used in a mild application not needing it. |

| Market Availability | Very high. Most common stock item. | Readily available, but may be less common in general stock. |

Scenario Analysis: Making the Right Call

Let’s walk through common situations Rajesh might encounter with his customers:

-

Scenario 1: Replacement for a Standard Conveyor Drive.

- The old bearing was C3 and lasted 3 years. The machine runs normally.

- Choice: C3. There is no reason to change. Stick with what worked.

-

Scenario 2: Bearing for a Hot Running Industrial Fan.

- The customer says the fan housing gets very warm. Previous bearings failed from overheating.

- Choice: C4. The extra clearance of C4 will better compensate for the high thermal expansion, reducing the risk of seizure.

-

Scenario 3: Bearing for a Vibrating Screen.

- The application has oscillating loads and some inherent misalignment.

- Choice: This depends on the screen design. Often C3 is sufficient, but some manufacturers specify C4 to ensure the rollers never bind under the complex motion. Check the manual or consult the OEM.

-

Scenario 4: Customer Asks for "The Best Quality" and Assumes C4 is Higher Grade.

- This is a misconception. C4 is not a higher quality grade; it’s a different fit.

- Action: Educate the customer. Explain that using a C4 in a standard application might lead to increased noise and reduced precision. Recommend C3 for their standard use, as it is the optimal fit, not a compromise.

The Role of the Knowledgeable Distributor

This is where Rajesh can truly add value. When a customer places an order, he can ask a few simple questions: "Is this a direct replacement?" "Does the machine run particularly hot?" "Were there any issues with the old bearing like overheating or noise?" Based on the answers, he can confirm if the standard C3 is correct or if he should propose C4. This proactive approach reduces returns, increases customer satisfaction, and establishes his company as a technical expert, not just a warehouse.

Conclusion

Specifying the correct internal clearance (C3, C4, C5) is not a minor detail. It is a fundamental engineering decision that directly determines bearing performance, temperature, noise, and service life. Always match the clearance to the application’s thermal and mechanical environment.