I see bearings fail every day. Many times, the root cause is not a bad bearing, but a silent killer called misalignment. It shortens bearing life dramatically.

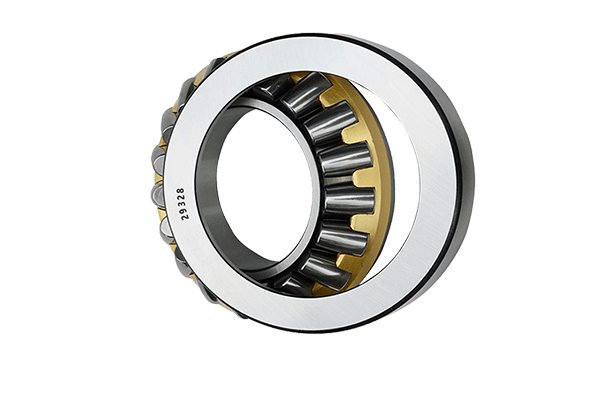

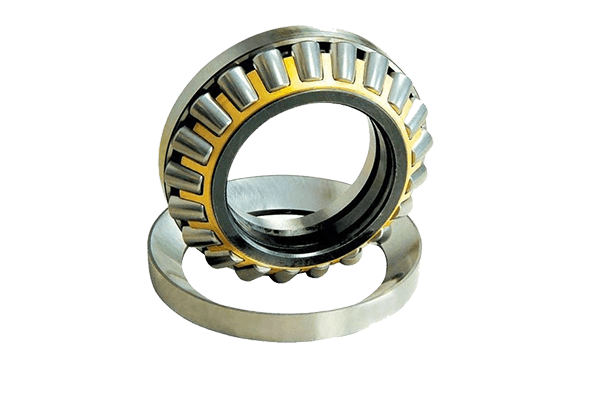

Spherical roller bearings compensate for misalignment through their unique design. The outer ring has a spherical raceway, and the rollers are barrel-shaped. This allows the inner ring, rollers, and cage to tilt or pivot inside the outer ring, accommodating angular shaft misalignment without creating destructive internal forces.

Misalignment is inevitable in the real world of machinery. Frames bend, shafts sag under load, and foundations settle. A rigid bearing cannot tolerate these shifts. It fights against them, leading to heat, noise, and premature failure. Understanding how spherical roller bearings solve this fundamental problem is key to selecting the right component for reliable operation. Let’s explore this critical feature in detail.

This is the first question many engineers and buyers like Rajesh ask. They have a noisy pump or a hot-running conveyor idler and suspect alignment issues.

Yes, spherical roller bearings are specifically designed to handle misalignment. They are known as "self-aligning" bearings because they can accommodate angular misalignment between the shaft and the housing, typically between 1.5 to 3 degrees, depending on the series and size.

The simple answer is yes, but the "how" is what makes them special. They don’t just endure misalignment; they actively accommodate it.

Let’s break down exactly what happens inside the bearing when the shaft is not perfectly straight. This is not magic; it’s precise mechanical engineering.

The Core Design Elements

Two features work together:

The Compensation Process in Action

Imagine mounting the bearing. The outer ring is fixed in the housing. The inner ring is pressed onto the shaft. If the shaft deflects under load or was installed at a slight angle, here is what occurs:

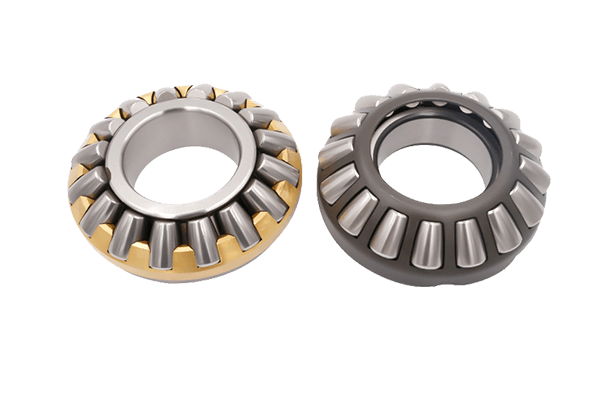

Contrast with a Non-Self-Aligning Bearing

For comparison, think of a standard cylindrical roller bearing. Its outer ring raceway is a straight cylinder. If the shaft tries to tilt, the inner ring tilts, but the outer ring cannot. The rollers get pinched. Their ends dig into the raceway shoulders. This causes severe edge loading, rapid heat generation, high friction, and ultimately, spalling (surface fatigue) and failure. The bearing fights the misalignment until it loses.

A Real-World Example from Our Clients

A distributor in Egypt supplies bearings to large agricultural irrigation systems. The long pump shafts often deflect due to water pressure and uneven ground. They used to have constant failures with deep groove ball bearings on these pumps. The bearings would overheat and seize within months. We recommended switching to spherical roller bearings for the main pump support. The self-alignment feature absorbed the shaft deflection. The bearing failures stopped. The client’s maintenance costs dropped significantly. For Rajesh in India, this is a powerful story. When his customers in factories complain about frequent bearing changes on equipment with long shafts or flexible frames, suggesting a self-aligning spherical roller bearing isn’t just a sale—it’s providing a lasting solution.

Knowing a bearing can handle misalignment is good. Knowing exactly how much is critical for engineering design and troubleshooting.

The typical angular misalignment tolerance for spherical roller bearings is between 0.5 and 3 degrees. For most standard series (like 21300, 22200, 22300), the practical allowance is about 1.5 to 2.5 degrees. This is significantly higher than the near-zero tolerance of bearings like cylindrical rollers.

Tolerance is not a single number. It depends on many factors. Pushing a bearing to its theoretical limit in daily operation is a recipe for reduced life.

The catalog number is a starting point. In the field, other elements come into play. Let’s examine them.

Bearing Design and Series

Different spherical roller bearing series are optimized for different things. A bearing designed for extremely high load capacity might have a slightly lower misalignment allowance than one designed for general industry use. The curvature radius of the outer ring raceway determines the pivot point and range.

| Operating Conditions: The Big Variables | Factor | Effect on Misalignment Tolerance | Reason |

|---|---|---|---|

| Load | High load reduces effective tolerance. | Under heavy load, the rollers press deeply into the raceways. This makes it mechanically harder for the inner assembly to pivot smoothly. The bearing becomes "stiffer." | |

| Speed | High speed reduces effective tolerance. | At high RPMs, centrifugal force throws the rollers outward against the outer ring. This also restricts the free pivoting motion needed for alignment. | |

| Internal Clearance | Larger clearance allows for more alignment. | A bearing with a C3 or C4 radial internal clearance group has more space between the rollers and raceways. This extra space can be used to accommodate misalignment before the components bind. | |

| Lubrication | Inadequate lubrication reduces tolerance. | Proper lubrication forms a film that allows surfaces to slide slightly during the self-aligning action. Poor lubrication increases friction and can cause scuffing during alignment movement. |

The Cost of Exceeding the Limit

Even self-aligning bearings have a breaking point. If misalignment exceeds the design tolerance, several problems occur:

Guidance for Procurement and Application

For a buyer like Rajesh, this information is practical. When a customer asks for a spherical roller bearing, Rajesh should ask about the application. Is it for a slow-moving, heavily loaded mining cart? Or is it for a faster-running fan shaft? The expected misalignment might be similar, but the operating conditions change which bearing series or internal clearance is best. We often advise our distributors to recommend a bearing with a C3 clearance for most industrial applications where some misalignment and heat expansion are expected. This gives a better safety margin. The tolerance isn’t just a number on paper; it’s a living parameter that interacts with the machine’s entire environment.

Spherical rollers are excellent, but they are not the only self-aligning option. The "best" choice depends on the specific mix of load, speed, and cost.

For handling significant misalignment under heavy radial loads, spherical roller bearings are the best. For lighter loads and higher speeds, self-aligning ball bearings are a good choice. For simple support with very high misalignment in low-load situations, spherical plain bearings or rod ends may be used.

Choosing the right tool means looking at the whole toolbox. Let’s compare the main contenders in the "misalignment compensation" category.

We will look at four common bearing types that offer some form of misalignment accommodation. Each has its champion application area.

1. Spherical Roller Bearings (The Heavyweight Champion)

2. Self-Aligning Ball Bearings (The All-Rounder)

3. Spherical Plain Bearings / Rod Ends (The Articulation Specialist)

4. CARB Toroidal Roller Bearings (The Niche Innovator)

Making the Choice for Your Business

For an importer/distributor, stocking decisions matter. If Rajesh’s main market is industrial maintenance (conveyors, crushers), focusing on spherical roller bearings is smart. If he also supplies lighter machinery workshops, having self-aligning ball bearings in stock completes his portfolio. The "best" bearing is the one that solves the customer’s specific problem most reliably and cost-effectively. I always tell our partners: "Don’t just sell a bearing. Sell the right bearing for the job." This builds long-term trust and reduces costly returns from failed applications.

Before we can fix a problem, we must define it clearly. Misalignment is often invisible to the naked eye but devastating to bearings.

Bearing misalignment is the condition where the axes of the bearing’s inner ring (shaft) and outer ring (housing) are not perfectly parallel or collinear. This creates uneven load distribution inside the bearing, leading to increased stress, heat, vibration, and premature failure.

Misalignment is a silent enemy. A few thousandths of an inch or a fraction of a degree off can cut a bearing’s life by 80% or more. It’s crucial for anyone involved in machinery maintenance or parts supply to recognize its forms and causes.

Misalignment isn’t just one thing. It manifests in different ways, each with its own challenges. Understanding these types helps in diagnosis and prevention.

The Three Main Types of Misalignment

Common Sources of Misalignment in Industrial Settings

Misalignment doesn’t always start during installation. It develops over time. Here are the usual suspects:

The Direct Consequences of Misalignment

Let’s trace the cause-and-effect chain inside a non-self-aligning bearing:

The Role of the Bearing Distributor

For someone like Rajesh, this knowledge is power. When a customer from a local cement plant brings in a failed bearing that shows clear signs of edge loading (wear marks only on one side), Rajesh can do more than just sell a replacement. He can ask intelligent questions: "Was the shaft checked for straightness?" "Could the foundation have shifted?" By educating his customers about the root causes of failure, he moves from being a parts vendor to a technical advisor. This is how strong, long-term business partnerships are built. At FYTZ, we train our distributors on these fundamentals so they can add value to their own customers.

Bearing misalignment is a major cause of premature failure, but it doesn’t have to be. By understanding its types, causes, and especially by selecting bearings designed to compensate for it—like spherical roller bearings—you can build more reliable and durable machinery.