Your machine is down. You need a replacement bearing fast. But the options are confusing, and picking the wrong one means more downtime and cost. This is a daily stress for maintenance managers and buyers. I help people like Rajesh solve this exact problem every week.

To choose the right deep groove ball bearing, you need four key pieces of information: the shaft size, the load type and magnitude, the required speed, and the operating environment. Match these to the bearing’s dimensions (bore, OD, width), load ratings, cage type, and seal options. Standard series like 6000 or 6200 are common starters.

The basic selection process is clear. But knowing what to choose is different from knowing how to figure it out. You might have an old, unmarked bearing or a new design on your desk. The next sections will guide you through the practical steps. We will cover how to identify a bearing, where to use it, how to read sizes, and how to compare common types.

How do you figure out what bearing you need?

A broken bearing sits on your bench with no markings. Or you are designing a new product and must specify a bearing from scratch. The uncertainty is frustrating. A wrong guess leads to wasted time and money. I have seen many clients order the wrong bearing because they missed one critical detail.

You figure out what bearing you need by gathering key application data: measure the old bearing’s dimensions (bore, outer diameter, width), estimate the loads and speed, and note environmental factors like heat or dust. For new designs, calculate the loads and consult bearing manufacturer catalogs or engineers to select the appropriate type, size, and configuration.

This process seems straightforward. But each step has potential pitfalls that can derail your selection. To do this reliably, we need a systematic checklist. This checklist turns a guessing game into a clear procedure.

A Step-by-Step Bearing Identification Checklist

Think of selecting a bearing like solving a puzzle. You need all the pieces in the right place. Follow this structured approach to find the correct bearing every time.

Step 1: Gather Physical Dimensions (For Replacement).

If you have an old bearing, precise measurement is your first and most reliable step. Use calipers, not a ruler.

| Dimension to Measure | How to Measure | Why It’s Important |

|---|---|---|

| Bore Diameter (d) | Measure the inner ring’s inside diameter. | This must fit your shaft perfectly. A loose or tight fit causes failure. |

| Outer Diameter (D) | Measure the outer ring’s outside diameter. | This must fit your housing perfectly. |

| Width (B) | Measure the total height/thickness of the bearing. | This ensures the bearing fits in the axial space provided. |

Step 2: Understand the Application Context.

The dimensions tell you the size, but not the bearing’s capability. You must ask questions about the job it does.

- What kind of loads are present? Is it mainly radial (like a pulley), axial (like a vertical fan), or both? How heavy are the loads? Light, moderate, or heavy?

- What is the operating speed? Is it a low-speed conveyor or a high-speed electric motor?

- What is the environment? Is it dry, dusty, wet, or exposed to chemicals? What is the temperature range?

Step 3: Identify the Bearing Type & Features.

Now, match your findings to bearing characteristics.

- Type Confirmation: Deep groove ball bearings are the most common. They handle moderate radial and light axial loads. If your load is very heavy or mostly axial, you might need a different type (like a tapered roller bearing).

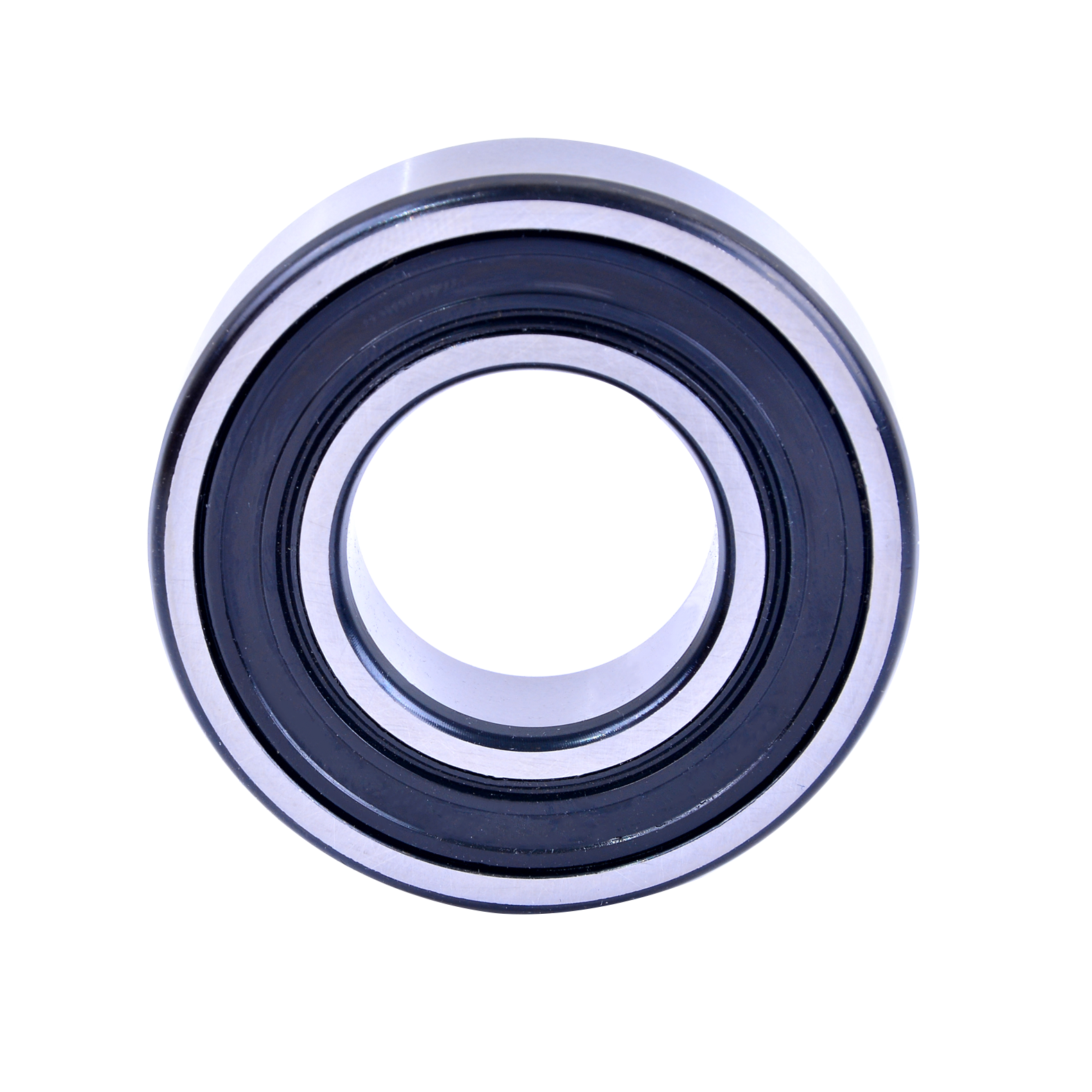

- Seal/Shield Type: Look at the old bearing. Does it have rubber seals (RS, 2RS) or metal shields (Z, ZZ)? Seals keep grease in and dirt out. This is critical for life.

- Cage Material: Is the cage metal (steel, brass) or plastic (often nylon)? Plastic cages are quieter and better for high speeds but have temperature limits.

- Precision Class: For most industrial repairs, a standard (P0) class is fine. For precision spindles or high-speed applications, you may need P6 or P5.

Step 4: Consult Reference or an Expert.

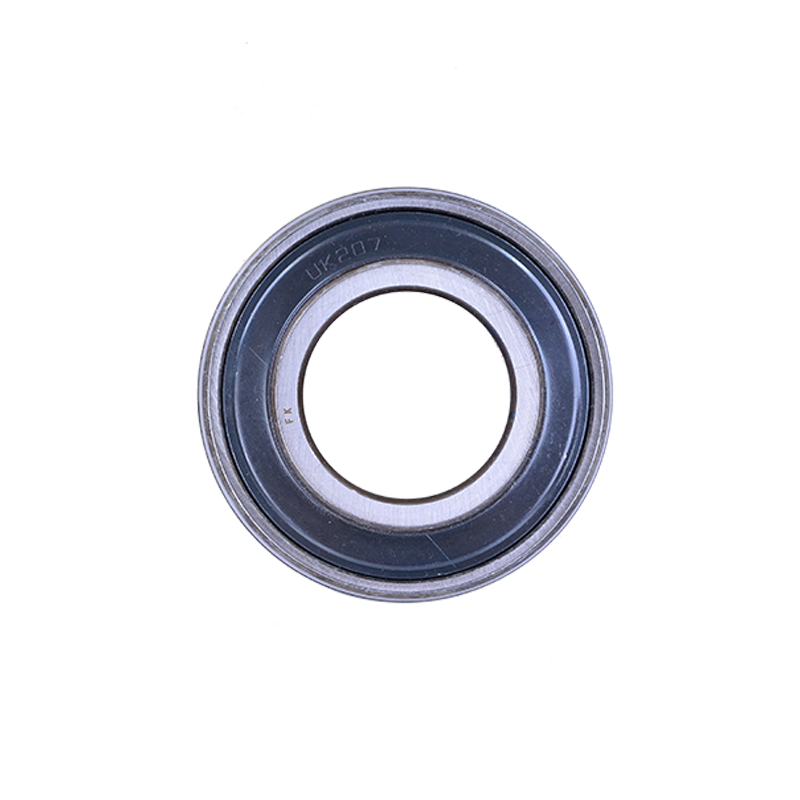

Use your measurements (e.g., 25mm bore, 52mm OD, 15mm width) to look up a standard bearing number (e.g., 6205). Cross-check this number with the application needs. If you are unsure, send the details and photos to a bearing supplier. A good supplier, like our team at FYTZ, can identify it quickly.

From my experience, the most common mistake is only measuring the bore. A client in Egypt once ordered bearings based on shaft size alone. The bearings arrived, and the outer diameter was too large for the housing. We had to re-ship the correct size, causing a two-week delay. Now, we always ask for all three dimensions and a photo. A systematic approach saves everyone time and trouble.

What are the applications of deep groove ball bearings?

You see deep groove ball bearings everywhere. They are cheap and common. But this leads to a problem: people use them for everything, even when another bearing would work better. Misapplication causes premature failure. You need to know their true strengths and limits.

Deep groove ball bearings are versatile. Their main applications are in electric motors, household appliances, automotive components (like alternators and pumps), general machinery, and power tools. They are ideal for moderate radial loads, high speeds, and applications requiring low noise and friction.

Saying they are "versatile" is true but vague. To use them correctly, you must understand exactly why they fit these applications and where they should not be used. Let’s map their capabilities to real-world uses and warn against common misapplications.

The Right and Wrong Jobs for Deep Groove Ball Bearings

Deep groove ball bearings are the "general-purpose" soldier of the bearing world. They perform well in many standard battles but are not equipped for every war.

Ideal Applications (Where They Excel):

| Application Category | Specific Examples | Why Deep Groove Ball Bearings Are a Good Fit |

|---|---|---|

| Electric Motors & Generators | Small to medium AC/DC motors, fan motors, pump motors. | They handle moderate radial loads from the rotor, run at high speeds with low friction, and generate little noise. Sealed versions keep grease in for long life. |

| Appliance & Consumer Goods | Washing machine drums, dryer idler pulleys, power tool gearboxes, skateboards. | They are cost-effective, reliable, and can handle the loads and speeds in these products. Plastic cage versions (like our low-noise series) are very quiet. |

| Automotive Auxiliary Systems | Alternators, water pumps, air conditioning compressors, tensioner pulleys. | They manage the radial loads from belts and pulleys and can handle the under-hood temperatures when properly specified. |

| General Industrial Machinery | Light conveyor rollers, gearbox shafts, small agricultural equipment. | Their simplicity, availability, and ability to handle some misalignment make them a safe, standard choice for many designs. |

Poor Applications (Where to Choose Another Bearing):

This is the critical knowledge that prevents failure.

- Very Heavy Radial Loads: For heavy-duty conveyors, crushers, or large gearboxes, the point contact in ball bearings creates too much stress. Cylindrical or spherical roller bearings are better. They have line contact for higher capacity.

- Significant Axial (Thrust) Loads: While deep groove bearings can handle some axial load, they are not designed for continuous, heavy thrust. Applications like vertical pumps or screw conveyors with strong axial force need angular contact ball bearings or tapered roller bearings.

- Severe Misalignment: If the shaft is likely to bend or the mounting is not perfect, deep groove bearings will suffer. Self-aligning ball bearings or spherical roller bearings are designed for this.

- High-Precision Spindles: Standard deep groove bearings have too much runout for machine tool spindles. High-precision angular contact ball bearings (P4/P2 grade) are required.

A story from our client Rajesh illustrates this. He supplies bearings to local repair shops. A shop was repeatedly replacing the deep groove ball bearing in a heavy farm equipment gearbox. It failed every few months. Rajesh asked us for advice. We looked at the load and realized it was too high for a standard 6205 bearing. We recommended a 6305 bearing from our stock. The 6305 has the same bore but a larger outer diameter and width, giving it a much higher load rating. The failure stopped. The lesson is simple: deep groove ball bearings have a wide range, but you must select the right size and series for the job. Just because it fits the shaft doesn’t mean it fits the load.

What are the dimensions of a deep groove ball bearing to fit a 12mm shaft?

You have a 12mm shaft. You need a bearing. You search online and find many numbers: 6001, 6201, 6301. They all fit a 12mm shaft. This creates confusion. Which one is right? Choosing based only on the bore size is a common and costly error.

A deep groove ball bearing for a 12mm shaft has a standard bore diameter (d) of 12mm. However, it comes in several common series with different outer diameters (OD) and widths. The most common dimensions are: 6001 series (28mm OD, 8mm width), 6201 series (32mm OD, 10mm width), and 6301 series (37mm OD, 12mm width). You must choose based on the required load capacity and available housing space.

The bore is just one number. The complete dimensions and, more importantly, the load capacity change dramatically with the series. Picking the wrong series means your bearing will be either too weak or too large. Let’s break down the options to show you how to decide.

Decoding the "Series" for a 12mm Bore

The number after the "6" in a bearing code (like 6001, 6201, 6301) indicates the "width series" and indirectly the "diameter series." This code defines the bearing’s cross-sectional size and its load-carrying capability.

Comparison of Common 12mm Bore Bearings:

| Bearing Number | Bore (d) | Outer Diameter (D) | Width (B) | Key Difference: Load Capacity | Typical Use Case |

|---|---|---|---|---|---|

| 6001 | 12 mm | 28 mm | 8 mm | Lightest load capacity. Smallest cross-section. | Very compact spaces with minimal loads. Small fans, miniature motors, instruments. |

| 6201 | 12 mm | 32 mm | 10 mm | Moderate load capacity. The most common, standard series. | Electric motors (fractional horsepower), appliances, general machinery. Our best-seller. |

| 6301 | 12 mm | 37 mm | 12 mm | Heavy load capacity. Largest cross-section for this bore size. | Applications needing more strength: tougher gearboxes, heavier pulleys, small pumps with higher loads. |

| 61801 (Thin Section) | 12 mm | 21 mm | 5 mm | Very low capacity, ultra-thin. | Where space is extremely limited radially, but loads are minimal. |

How to Choose Among Them:

- Check Your Housing: First, measure the housing bore. A 6001 bearing (28mm OD) will rattle in a housing made for a 6301 (37mm OD). The housing must match the bearing’s outer diameter.

- Consider the Load: If you are replacing a bearing that failed from overload, you should upsize the series. For example, if a 6201 failed, try a 6301. It has roughly 50-70% higher dynamic load rating. This often solves chronic failure problems.

- Consider the Width (Axial Space): Make sure there is enough room for the bearing’s width. A 6301 (12mm wide) is thicker than a 6001 (8mm wide).

In our factory, we produce all these series. When a customer like a small motor manufacturer in Vietnam asks for bearings for a 12mm shaft, we never just send 6201. We ask: "What is the housing diameter? What is the load? What failed before?" Often, they are using a 6001 to save cost, but the motor runs hot and the bearing life is short. We suggest moving to a 6201. The small increase in cost leads to a large increase in reliability and customer satisfaction. The dimensions for a 12mm shaft are not a single answer. They are a menu. You choose from the menu based on the strength you need and the space you have.

What is the difference between 6205 and 6206 bearing?

You have two bearing numbers: 6205 and 6206. They look almost the same. It’s easy to mix them up. Using the wrong one will stop your machine from assembling or cause it to fail. Understanding the numbering system is key to avoiding simple, expensive mistakes.

The difference between a 6205 and a 6206 bearing is their size. Both are from the common "02" width series. The 6205 has a 25mm bore, 52mm outer diameter, and 15mm width. The 6206 has a 30mm bore, 62mm outer diameter, and 16mm width. The 6206 is larger in all dimensions and has a significantly higher load capacity.

The size difference is clear. But this comparison teaches a much more valuable lesson: how to read any standard bearing number. Once you understand the code, you can decode the specifications of thousands of bearings without a catalog. Let’s crack this code.

Understanding the Bearing Numbering System (ISO)

The numbers are not random. They follow an international standard (ISO). The code "6205" or "6206" is a compact set of instructions.

Breaking Down the Code: 6 2 05

- First Digit (Type Code):

6means Deep Groove Ball Bearing. (Example:3would be a Tapered Roller Bearing,2a Spherical Roller Bearing). - Second Digit (Width/Profile Series):

2refers to the "light" or "02" width series. This defines the proportional relationship between the bore, outer diameter, and width. A3would be a "medium" series, and a4a "heavy" series. - Last Two Digits (Bore Size Code): This is the most important part for identification.

- For bore sizes from 20mm to 480mm, the rule is: Multiply the last two digits by 5 to get the bore diameter in mm.

05x 5 = 25mm bore.06x 5 = 30mm bore.

Applying the Code to Compare 6205 vs. 6206:

| Feature | Bearing 6205 | Bearing 6206 | What This Means |

|---|---|---|---|

| Decoded Meaning | Type 6 (Deep Groove), Series 2 (Light), Bore 05 (25mm) |

Type 6 (Deep Groove), Series 2 (Light), Bore 06 (30mm) |

They are the same type and series, just for different shaft sizes. |

| Bore (d) | 25 mm | 30 mm | They fit different shafts. They are not interchangeable. |

| Outer Diameter (D) | 52 mm | 62 mm | The housing must be machined to the correct size. |

| Width (B) | 15 mm | 16 mm | The 6206 is slightly wider, needing a bit more axial space. |

| Dynamic Load Rating (C) | ~14 kN (example) | ~19.5 kN (example) | The 6206, being larger, can handle about 40% more load. |

Why This Matters for Your Business:

For a distributor like Rajesh, understanding this is crucial for inventory management. If a customer asks for a "25mm bearing," Rajesh knows to look for numbers ending in 05 (like 6005, 6205, 6305). He then asks about the housing size to pick the correct series. It also helps avoid errors. I once had a client in Brazil who urgently ordered "100pcs of 6205." We shipped them. He called back, angry, saying they were too small. After checking, he realized his mechanic had written down the wrong number from the old bearing. The actual needed part was 6206. We had to manage a costly cross-shipment. Now, we always advise clients to double-check the number and physically measure the old part if possible. The difference between 6205 and 6206 is just 5mm in bore, but in the world of machinery, that small difference is everything.

Conclusion

Choosing the right bearing is a logical process. Measure carefully, understand the application, decode the part numbers, and match the bearing’s capabilities to the job’s demands. This ensures reliability and saves time and money.