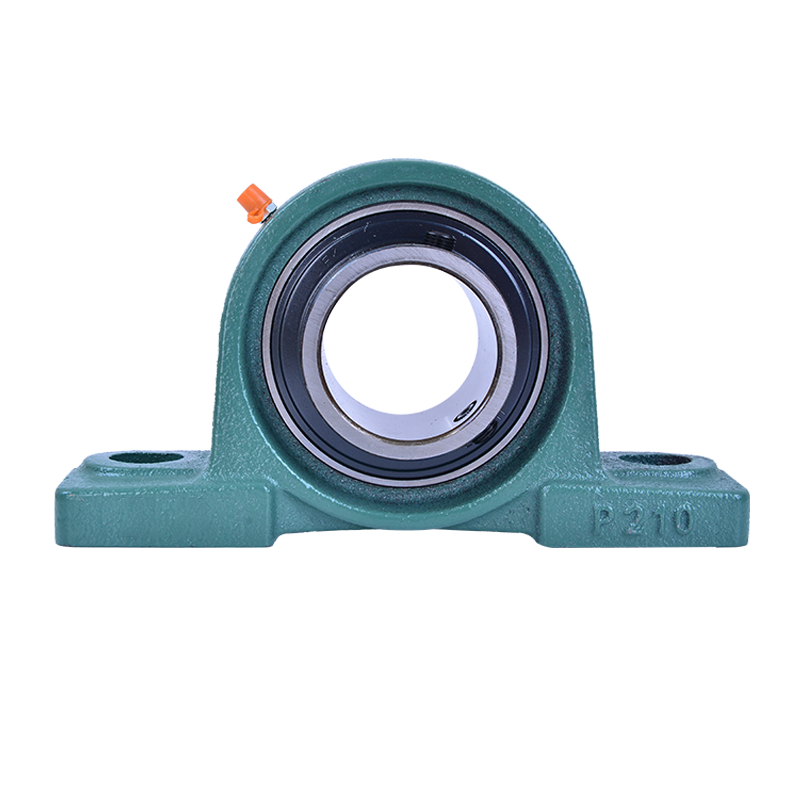

Choosing the wrong pillow block housing can lead to misalignment, vibration, and premature bearing failure. I have seen equipment damaged because of this simple choice. The housing is not just a cover; it’s the foundation for your entire bearing assembly.

The choice between cast iron and pressed steel pillow block housings depends on your specific needs. Cast iron offers superior vibration damping, strength, and heat dissipation for heavy-duty, high-load applications. Pressed steel provides a lighter weight, cost-effective, and corrosion-resistant solution for medium-duty, high-speed, or washdown environments. Knowing the difference protects your investment.

This decision impacts cost, performance, and maintenance. Let’s look beyond the surface. We will examine the materials, solve common problems, and even explore related bearing choices. This knowledge helps you specify the right component for every job and avoid costly mistakes.

Which is better cast iron or steel iron?

This question is common, but it’s not about which material is universally "better." I’ve had clients insist on cast iron for a lightweight conveyor, wasting money and adding stress to the frame. The real question is: which material is better for your specific situation? The answer lies in their inherent properties.

Neither cast iron nor pressed steel is inherently better; each excels in different scenarios. Cast iron is superior for applications demanding high rigidity, vibration damping, and heat dissipation under heavy loads. Pressed steel is better for applications prioritizing lightweight construction, cost efficiency, and resistance to corrosion in less demanding environments.

Breaking Down the Material Showdown

To choose wisely, you need to understand why these materials behave so differently. Let’s compare them across the key factors that matter for a pillow block housing.

1. The Core Difference: How They Are Made

This manufacturing process defines their structure.

- Cast Iron: It is melted and poured into a mold (a sand casting). As it cools, carbon forms into flakes of graphite within the iron matrix. These graphite flakes are key. They give cast iron its unique ability to dampen vibrations. The process allows for complex, thick, and rigid shapes.

- Pressed Steel (Steel Plate): It starts as a flat sheet or coil of low-carbon steel. This sheet is stamped, pressed, and welded into shape. The result is a uniform, dense structure without the internal graphite. It is inherently lighter and more consistent in thickness.

2. Performance Comparison: A Detailed Look

Here is how they stack up in a real application:

| Property / Characteristic | Cast Iron Housing | Pressed Steel Housing | Why It Matters for Your Application |

|---|---|---|---|

| Vibration Damping | Excellent. Graphite flakes absorb vibrational energy. | Poor. Steel transmits vibrations more easily. | Critical for motors, gearboxes, and heavy machinery. Reduces noise and prevents bearing damage from resonance. |

| Strength & Rigidity | High compressive strength, good rigidity. Brittle under impact. | High tensile strength, good rigidity. More ductile, can deform under impact without cracking. | Cast iron handles heavy, steady loads well. Pressed steel better resists shock loads and bending forces. |

| Weight | Heavy. Significant mass. | Light. Can be 40-60% lighter for a similar size. | Impacts frame design, portability, and energy use in moving parts (e.g., conveyor rollers). |

| Heat Dissipation | Good. The mass and thermal properties help spread heat from the bearing. | Fair. Less mass means less heat capacity, but steel conducts heat well. | Important for high-speed or high-friction applications to prevent lubricant breakdown. |

| Corrosion Resistance | Poor. Prone to rust unless painted or coated. | Better. Can be made from pre-galvanized or stainless steel sheets for excellent corrosion resistance. | A deciding factor for food processing, chemical, marine, or washdown environments. |

| Cost | Higher. Due to material, molding, and machining costs. | Lower. Efficient stamping process and less material. | Impacts your project budget and final product cost, especially for high-volume orders. |

| Machinability & Complexity | Easy to machine after casting. Complex shapes are possible. | Shapes are limited by stamping/pressing tools. Simple, consistent geometries. | Cast iron allows for integrated features like cooling fins or special mounting lugs. Pressed steel is ideal for standardized, high-volume parts. |

3. Making the Practical Choice

Think about your application like my client Rajesh does for his customers in India.

- Choose Cast Iron For: Large industrial fans, heavy-duty conveyor head/tail pulleys, mining equipment, pump bases, and motor mounts. Anywhere you need mass to resist movement and dampen operational shocks.

- Choose Pressed Steel For: Light to medium-duty conveyors, agricultural machinery, packaging equipment, food-grade applications (with proper coating), and any situation where weight savings or corrosion resistance is a priority.

Remember, at FYTZ Bearing, we offer both. Our advice is based on helping you match the housing to the job’s real demands, not just a material preference.

What are the common problems with pillow blocks?

A failed pillow block can stop a production line. Over the years, I’ve diagnosed hundreds of failures. The problem is rarely just "a bad bearing." Often, the housing or its installation is at fault. Knowing these common issues helps you prevent them, saving time and money on maintenance.

Common pillow block problems include bearing failure from contamination or poor lubrication, housing damage from misalignment or improper mounting, and loosening due to inadequate locking or thermal expansion. Many issues stem not from the component itself, but from incorrect selection, installation, or maintenance practices.

Diagnosing and Preventing Frequent Failures

Let’s move from listing problems to understanding their root causes. This knowledge turns you from a parts replacer into a problem solver.

1. Bearing-Specific Failures Inside the Housing

The bearing is the heart, but the housing is its environment.

- Contamination Ingress: This is the number one cause of premature wear. Dust, grit, and water enter through damaged seals, gaps between the housing and shaft, or even through the breather hole if installed in a dirty environment. The abrasive particles act like lapping compound, quickly wearing down races and balls. Solution: Select housings with effective sealing solutions (labyrinth seals, V-ring seals for harsh conditions). Ensure seals are in good condition during installation.

- Improper Lubrication: Too much, too little, or the wrong type of grease. Over-greasing creates heat from churning. Under-greasing leads to metal-on-metal contact. Incompatible greases can break down or react chemically. Solution: Follow the manufacturer’s lubrication guidelines. Use a grease gun with a pressure gauge. For food-grade or high-temperature applications, specify the correct lubricant from the start.

- Electrical Arcing (Fluting): In motors or applications with stray electrical currents, current can pass through the bearing, causing tiny pits or a washboard pattern on the races. This creates noise and rapid failure. Solution: Use insulated bearings or grounding brushes to divert current away from the bearing.

2. Housing and Mounting-Related Problems

The housing must provide a stable, aligned foundation.

- Misalignment: This is a silent killer. It happens when the shaft and housing bore are not perfectly parallel (angular misalignment) or when two pillow blocks supporting one shaft are not in line (offset misalignment). This forces the bearing to run under constant stress, leading to overheating and early fatigue. Solution: Use a straight edge or laser alignment tool during installation. For applications prone to shaft deflection, consider self-aligning bearing inserts (like those in spherical roller bearings) within the housing.

- Improper Mounting (Brute Force): Hammering a bearing into place or using the wrong tools damages both the bearing and the housing seat. It can dent races, crack cages, or distort the housing. Solution: Always use proper mounting tools—induction heaters for inner rings, presses, or specialized sleeve tools. Never apply force through the rolling elements.

- "Walking" or Creeping: The housing or the bearing inner ring can slowly rotate on its seat due to vibration or insufficient fit. This wears down the mounting surfaces. Solution: Ensure the correct fit (interference fit for the inner ring on the shaft, snug fit for the housing in its base). Use locking collars or adapter sleeves correctly, tightening them to the specified torque.

- Corrosion of the Housing: Especially for cast iron, rust can expand and seize mounting bolts or even distort the housing bore. Solution: Specify painted, coated, or stainless-steel housings for corrosive environments. Ensure proper storage before installation.

3. The Importance of Proactive Practices

Many problems are avoided before the pillow block is even installed.

- Wrong Selection: Using a light-duty pressed steel housing for a heavy shock-load application. Solution: Refer to the housing’s load rating and match it to the application, considering static and dynamic forces.

- Poor Storage: Storing bearings and housings in damp, dirty conditions invites corrosion and contamination before use. Solution: Keep original packaging intact until installation. Store in a clean, dry environment.

At our factory, we see these issues in returned parts. Our quality control helps, but correct application is the final, critical step. We provide technical data to help you make the right choice from the beginning.

Which type of ball bearing is best suited for applications with very high axial load and very high speed?

This question goes beyond pillow block housings, but it’s crucial. I often get asked for a "high-speed, high-thrust" bearing solution. A standard deep groove ball bearing will fail quickly here. You need a specialist bearing, and the housing must support its needs.

For applications with very high axial load and very high speed, Angular Contact Ball Bearings are the best-suited type. They are specifically designed with a built-in contact angle between the balls and raceways to manage substantial axial forces efficiently while maintaining high-speed rotational capability.

Why Angular Contact Bearings Dominate This Niche

Deep groove ball bearings are generalists. Angular contact bearings are specialists for combined loads. Let’s explore their design and how to use them correctly.

1. The Design Principle: The Contact Angle

This is the key feature. In an angular contact bearing, the races are offset. This creates a defined contact angle (common ones are 15°, 25°, 30°, or 40°). This angle allows the bearing to resolve axial loads into radial forces that the balls can carry effectively.

- High Axial Load Capacity: The steeper the contact angle (e.g., 40°), the greater the axial load capacity. The bearing is literally designed to "shoulder" the thrust.

- High-Speed Operation: Despite the contact angle, they maintain the ball bearing’s advantage of low friction. They can achieve very high speeds, especially when paired with a phenolic resin cage or similar high-speed cage design. Precision grades (like the P5 we offer) are standard for these applications.

2. Configuration and Mounting: Critical for Success

You rarely use a single angular contact bearing. Their power comes from specific arrangements.

- Preload: Angular contact bearings are usually installed with a preload—a small, constant axial force applied internally. This eliminates internal clearance, increases rigidity, and improves rotational accuracy. This is essential for machine tools and spindles.

- Paired Mounting: They are commonly used in pairs (duplex), facing the same direction (DF) for very high axial load in one direction, or facing opposite directions (DB) to handle axial load in both directions. Sometimes, they are used in a tandem arrangement (DT) for extreme axial capacity in one direction. The housing and shaft must be machined to very tight tolerances to accommodate these precise setups.

3. Comparison with Other Options

It’s helpful to see why other bearings are less suitable for this specific combination of high speed and high axial load.

| Bearing Type | Suitability for High Axial Load | Suitability for Very High Speed | Key Limitation for This Combo |

|---|---|---|---|

| Deep Groove Ball Bearing | Poor/Moderate. No designed contact angle. | Excellent. | Under high axial load, balls can skid, causing extreme heat and failure at high speeds. |

| Cylindrical Roller Bearing | Very Poor (axial load must be handled separately). | Good/High. | Cannot handle any significant axial load by design. |

| Tapered Roller Bearing | Excellent. The best for extremely heavy axial loads. | Moderate. | Higher friction from line contact limits maximum speed compared to ball bearings. Not ideal for "very high speed." |

| Thrust Ball Bearing | Excellent for pure axial load. | Low/Moderate. | Designed only for axial loads. Cannot handle any radial load. Speed is limited. |

| Angular Contact Ball Bearing | Excellent. | Excellent. | The optimal balance for high axial load AND very high speed. |

4. Application Examples

Where would you specify an angular contact bearing in a pillow block? Typically, in high-performance applications:

- Machine Tool Spindles: High speed with axial cutting forces.

- High-Speed Pumps: Handling both radial impeller loads and axial thrust.

- Turbochargers: Extreme speeds with axial thrust from the turbine.

While a standard pillow block might not be used, specialized high-precision housings are designed for these bearings. At FYTZ, we understand these needs and can advise on or supply the complete bearing solution, from the high-performance bearing to a suitable housing.

Which type of cast iron is the hardest, most brittle, wear resistant, and difficult to grind?

This is a deep technical question about material science. While not all pillow blocks use this type, understanding cast iron grades matters. I specify materials for custom housing solutions. Knowing the extremes helps you appreciate the balance in standard grades like gray iron.

White Cast Iron is the hardest, most brittle, and most wear-resistant type, and it is notoriously difficult to machine or grind. Its extreme properties come from its unique microstructure, where nearly all carbon is locked into a hard, brittle compound called cementite, instead of forming graphite flakes.

The World of Cast Iron: From Gray to White

Cast iron isn’t one material. It’s a family. The different types are created by controlling the chemistry and cooling rate, which changes the form of carbon inside.

1. The Cast Iron Family Tree

The key difference is how the carbon is distributed:

- Gray Cast Iron (Flake Graphite Iron): This is the most common type for general machinery, including most cast iron pillow blocks. Carbon exists as graphite flakes. These flakes give it good strength, excellent vibration damping, and good machinability. The flakes act as chip breakers during cutting.

- Ductile Iron (Nodular Iron): Carbon forms into spherical nodules (tiny balls) through a special treatment. This makes it much stronger and more ductile (less brittle) than gray iron. It has good wear resistance and better impact toughness. It’s used for higher-stress components like crankshafts or heavy-duty gearboxes.

- Malleable Iron: Heat-treated white iron where the cementite breaks down into a more ductile form of carbon. It has good strength and some ability to deform without breaking.

- White Cast Iron: This is the outlier. It is not "white" in color visibly, but named for its white, crystalline fracture surface.

2. Why White Cast Iron Has Extreme Properties

Let’s break down its characteristics:

- Hardness & Wear Resistance: When molten iron with a certain composition cools very rapidly, the carbon has no time to form graphite. Instead, it combines with iron to form iron carbide (Fe3C), called cementite. Cementite is extremely hard (around 70 HRC). This hard network makes white iron incredibly resistant to abrasive wear. It’s used for the liner plates in ore crushers, slurry pump parts, and mill rolls.

- Brittleness: The continuous network of hard, brittle cementite makes the material prone to cracking under impact or tension. It has almost no ductility.

- Difficulty in Machining/Grinding: Its extreme hardness means standard cutting tools wear out instantly. It can only be shaped by grinding with special abrasive wheels, which is a slow and expensive process. It is often cast to near-net shape to minimize machining.

3. Practical Implications for Housings and Components

This table summarizes where you encounter these irons:

| Cast Iron Type | Key Characteristics | Common Uses in Industry | Relevance to Pillow Blocks & Bearings |

|---|---|---|---|

| Gray Cast Iron | Good strength, excellent vibration damping, good machinability, moderate wear resistance. | Machine bases, engine blocks, standard pillow block housings, gearbox cases. | The standard, balanced choice for most industrial pillow blocks. Absorbs vibration, is easy to machine to precision bores. |

| Ductile Iron | High strength, good ductility/toughness, good wear resistance, good machinability. | Crankshafts, heavy-duty gears, high-pressure valve bodies, heavy-duty truck components. | Used for high-load, high-stress pillow blocks where impact resistance is needed, but it is less common than gray iron. |

| White Cast Iron | Extreme hardness, extreme wear resistance, very brittle, very difficult to machine. | Crusher liners, shot blasting equipment, mill rolls, wear plates in mining. | Almost never used for complete pillow blocks. However, wear-resistant inserts or sleeves inside a housing might be made from a similar material (like chilled iron) in extreme abrasive environments. |

Conclusion for Your Application:

For a pillow block housing, you want Gray Cast Iron. It provides the perfect balance: it dampens vibration to protect the bearing, has enough strength for mounting loads, and can be accurately machined to provide a perfect, round seat for the bearing insert. The extreme properties of white iron are undesirable for a housing that needs to be bolted down and machined. At FYTZ, our standard cast iron housings use high-quality gray iron to ensure reliable performance and ease of installation for our clients worldwide.

Conclusion

Choose cast iron for heavy-duty stability and vibration control. Choose pressed steel for lightweight, cost-sensitive, or corrosive environments. Always match the housing and bearing to your application’s true demands for lasting performance.